Preparation method of slurry for lithium titanate battery

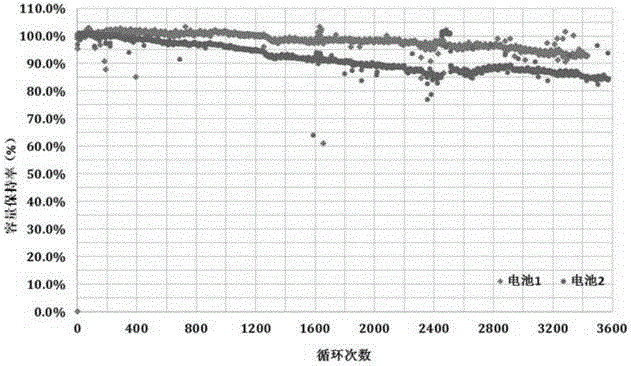

A lithium titanate battery and slurry technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as poor cycle performance, large irreversible capacity, hidden danger service life, etc., to improve long-term cycle performance and save preparation Time, the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment one, adopt stirring technique of the present invention:

[0030] In this embodiment, the positive electrode active material is lithium nickel cobalt manganese oxide, the negative electrode active material is lithium titanate, the binder is polyvinylidene fluoride (PVDF), the solvent is NMP, and the conductive agent is SP and KS-6. Among them, the positive electrode NCM: SP: KS-6: PVDF = 91:4:1:3; the negative electrode LTO: SP: KS-6: PVDF = 90:4:1:5.

[0031] Prepare positive electrode slurry:

[0032] (1) Add 3% of PVDF and 40% of the total amount of NMP solvent into the clean mixing tank A, revolutionize 20RPM, disperse at 1000RPM, vacuum degree -0.085MPa~-0.095MPa, stir for 1.5h, in the middle process Scrape twice with a Teflon scraper;

[0033] (2) At the same time, add 91% NCM, 4% SP and 1% KS-6 into the clean mixing tank B, revolutionize 20RPM, disperse at 800RPM, do not vacuum, and ensure that the mixing tank is in a sealed state, stir 1.5h, then st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com