Preparation method and application of iodine-doped graphene

A graphene and iodine doping technology, applied in the field of materials, can solve the problems of reduced electrical conductivity, insufficient contact between electrolyte and materials, and unsatisfactory electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method for iodine-doped graphene, comprising the following steps:

[0029] S1 Dissolve the iodine source in deionized water to prepare a solution I with a certain concentration;

[0030] S2 Prepare a certain concentration of graphene oxide suspension and add it to solution I. The mass ratio of graphene oxide in the graphene oxide suspension to iodide anions in solution I is 1:4 to 1:60, and mix well. Formation of mixed liquid II;

[0031] S3 Treat the mixed solution II with ultrasonic waves for 3-6 minutes;

[0032] S4 is transferred to a high-pressure reactor with a polytetrafluoroethylene liner for hydrothermal reaction at a temperature of 150°C to 200°C for 10 to 14 hours to reduce graphene oxide to graphene, and at the same time dope iodine into graphite In ene, adjust the layer spacing of graphene;

[0033] S5 washing the obtained product several times with deionized water, removing excess salt therein, and freeze-drying to obtain iodine-doped grap...

Embodiment 1

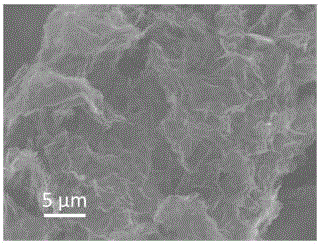

[0035] Example 1: Weigh 0.375 g of sodium iodide and dissolve it in 28 ml of deionized water, then add 12 ml of graphene oxide suspension (4.2 mg ml-1) into the solution, ultrasonicate for 5 min, and mix The solution was transferred to a 50 ml polytetrafluoroethylene liner autoclave, and reacted at 180 °C for 12 h. The resulting product was washed several times with deionized water to remove excess salt, and then freeze-dried to obtain iodine-doped composites of graphene. For the scanning electron microscope image of the prepared doped graphene, please refer to figure 1 , it can be seen from the figure that the iodine-doped graphene is relatively loose.

Embodiment 2

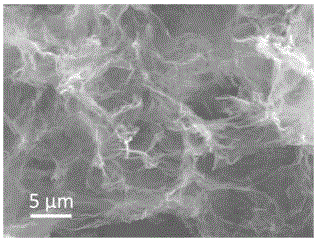

[0036] Example 2: Weigh 0.75 g of sodium iodide and dissolve it in 28 ml of deionized water, then add 12 ml of graphene oxide suspension (4.2 mg ml-1) into the solution, ultrasonicate for 5 min, and mix The solution was transferred to a 50 ml polytetrafluoroethylene liner autoclave, and reacted at 180 °C for 12 h. The resulting product was washed several times with deionized water to remove excess salt, and then freeze-dried to obtain iodine-doped composites of graphene. For the scanning electron microscope image of the prepared doped graphene, please refer to figure 2 , it can be seen from the figure that the iodine-doped graphene is relatively loose and wrinkled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com