Chlorine-magnesium battery and energy storage method thereof

A battery and magnesium chloride technology, applied in the direction of fuel cell half-cells and primary battery-type half-cells, can solve problems such as power supply and demand imbalances, achieve significant economic and social benefits, stabilize energy storage, and improve power grids Economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Electrolyte preparation: MgCl 2 , tetrahydrofuran and dimethoxymethane were mixed uniformly to make an electrolyte solution.

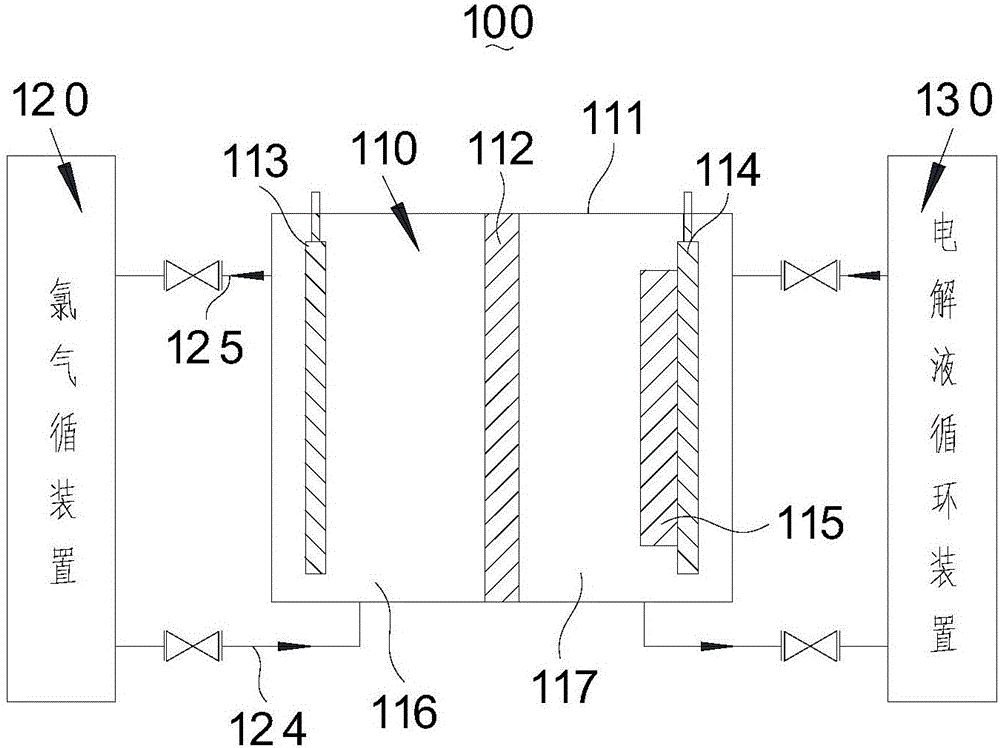

[0053] Preparation of the negative electrode plate 114: the negative electrode plate 114 is obtained by cold pressing and rolling iron and aluminum.

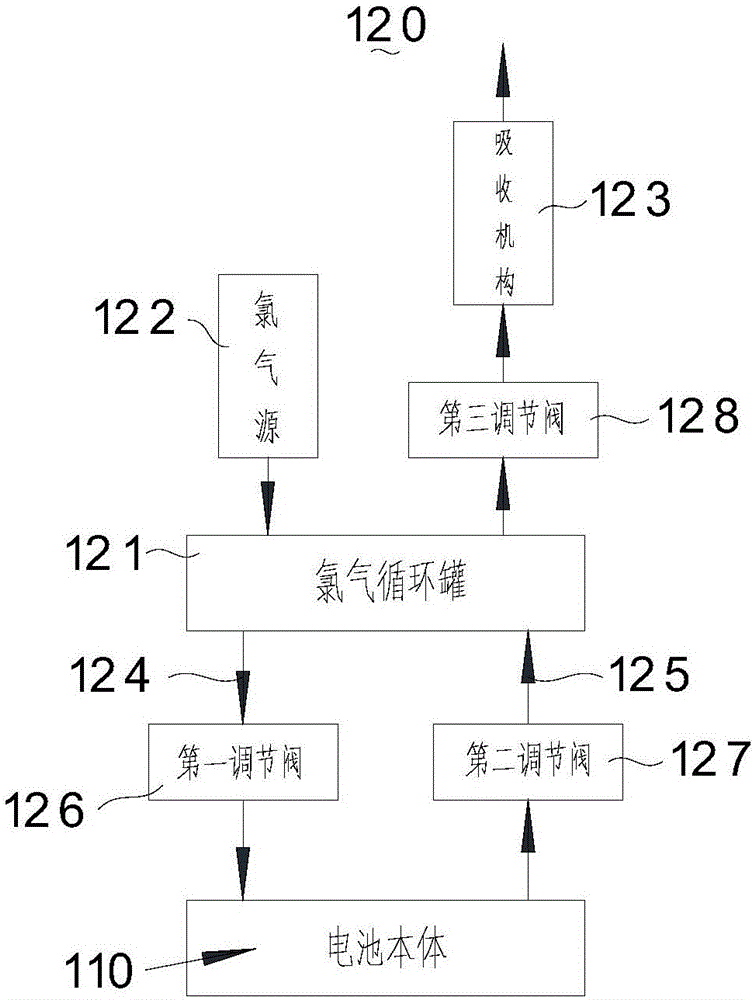

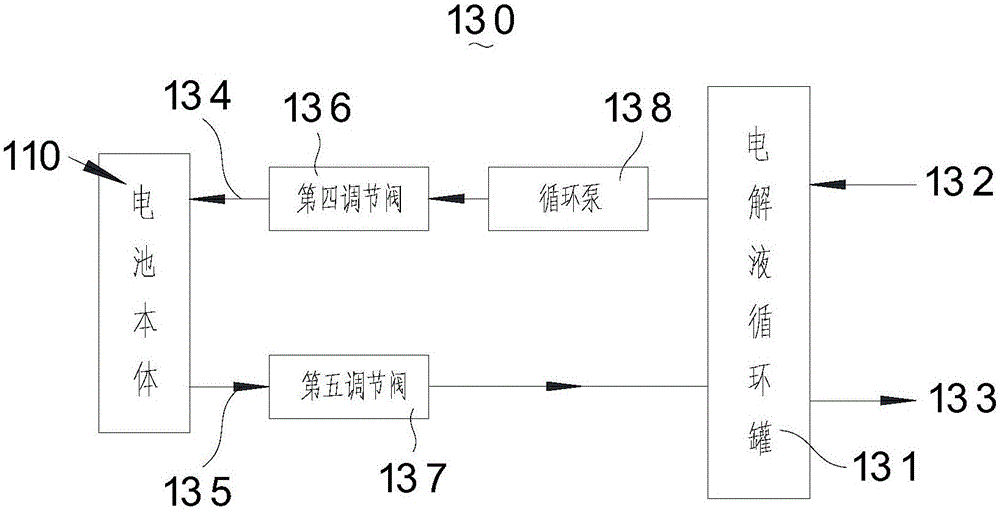

[0054] Assembling the magnesium chloride battery 100 : the platinum electrode is used as the positive plate 113 , the negative plate 114 prepared in the above steps and the membrane module 112 are packaged in the casing 111 and assembled into the battery body 110 . In an inert gas environment, electrolyte solution is injected into the battery body 110 and sealed. The assembled battery bodies 110 are connected in series and installed in the battery container, and the positive electrode area 116 of each battery body 110 is communicated with the chlorine gas circulation device 120 . The negative electrode region 117 of each battery body 110 is communicated with the electrolyte circulation device 13...

Embodiment 2

[0057] Electrolyte preparation: MgCl 2 , MgClO 4 , diethylene glycol dimethoxy ether, and tetraethylene glycol dimethyl ether were mixed evenly to make an electrolyte solution.

[0058] Preparation of the negative electrode plate 114: the negative electrode plate 114 is obtained by cold pressing and rolling iron and aluminum.

[0059] Assembling the magnesium chloride battery 100 : the platinum electrode is used as the positive plate 113 , the negative plate 114 prepared in the above steps and the membrane module 112 are packaged in the casing 111 and assembled into the battery body 110 . In an inert gas environment, electrolyte solution is injected into the battery body 110 and sealed. The assembled battery bodies 110 are connected in series and installed in the battery container, and the positive electrode area 116 of each battery body 110 is communicated with the chlorine gas circulation device 120 . The negative electrode region 117 of each battery body 110 is communica...

Embodiment 3

[0062] Electrolyte preparation: MgCl 2 , Mg(ClO 4 ) 2 , diethylene glycol dimethoxy ether and dimethoxymethane are mixed evenly to make an electrolyte solution.

[0063] Preparation of the negative electrode plate 114: the negative electrode plate 114 is obtained by cold pressing and rolling iron and aluminum.

[0064] Assembling the magnesium chloride battery 100 : the platinum electrode is used as the positive plate 113 , the negative plate 114 prepared in the above steps and the membrane module 112 are packaged in the casing 111 and assembled into the battery body 110 . In an inert gas environment, electrolyte solution is injected into the battery body 110 and sealed. The assembled battery bodies 110 are connected in series and installed in the battery container, and the positive electrode area 116 of each battery body 110 is communicated with the chlorine gas circulation device 120 . The negative electrode region 117 of each battery body 110 is communicated with the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com