High integration motor controller assembly

A technology that integrates motors and controllers. It is applied in the direction of connection with control/drive circuits, electrical components, and electromechanical devices. It can solve problems such as poor working environment of motor systems, and achieve convenient integration, improved flexibility, and optimized heat dissipation paths. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

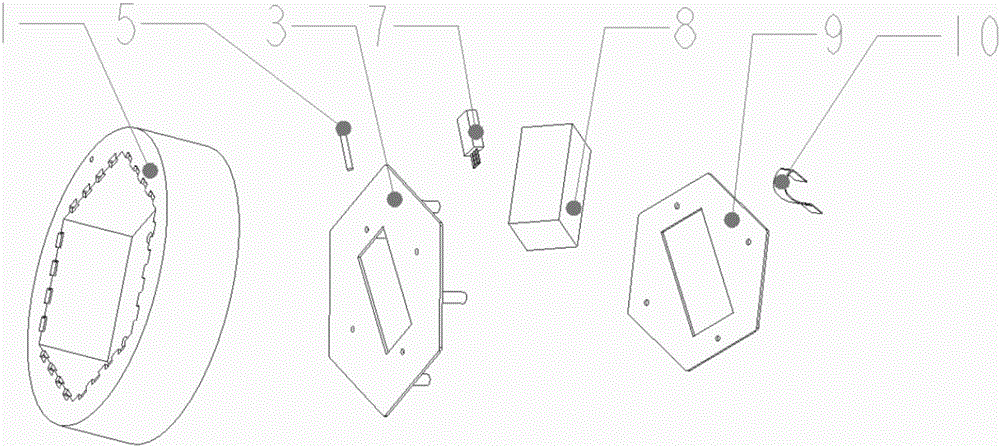

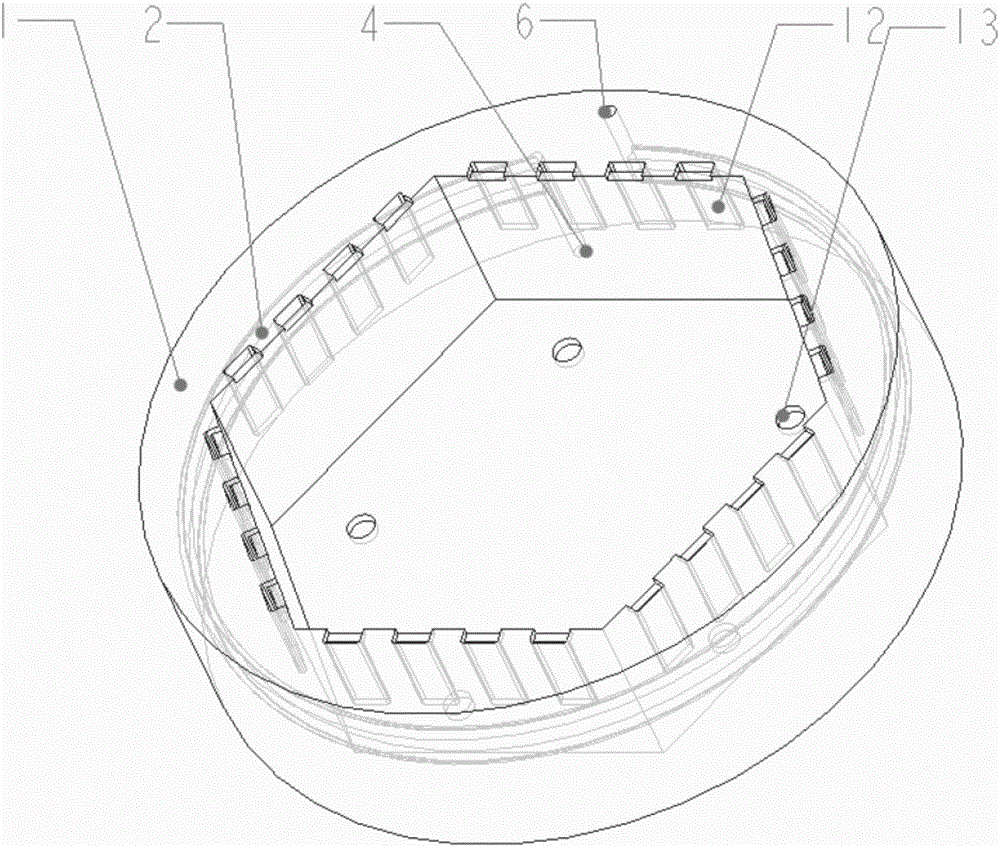

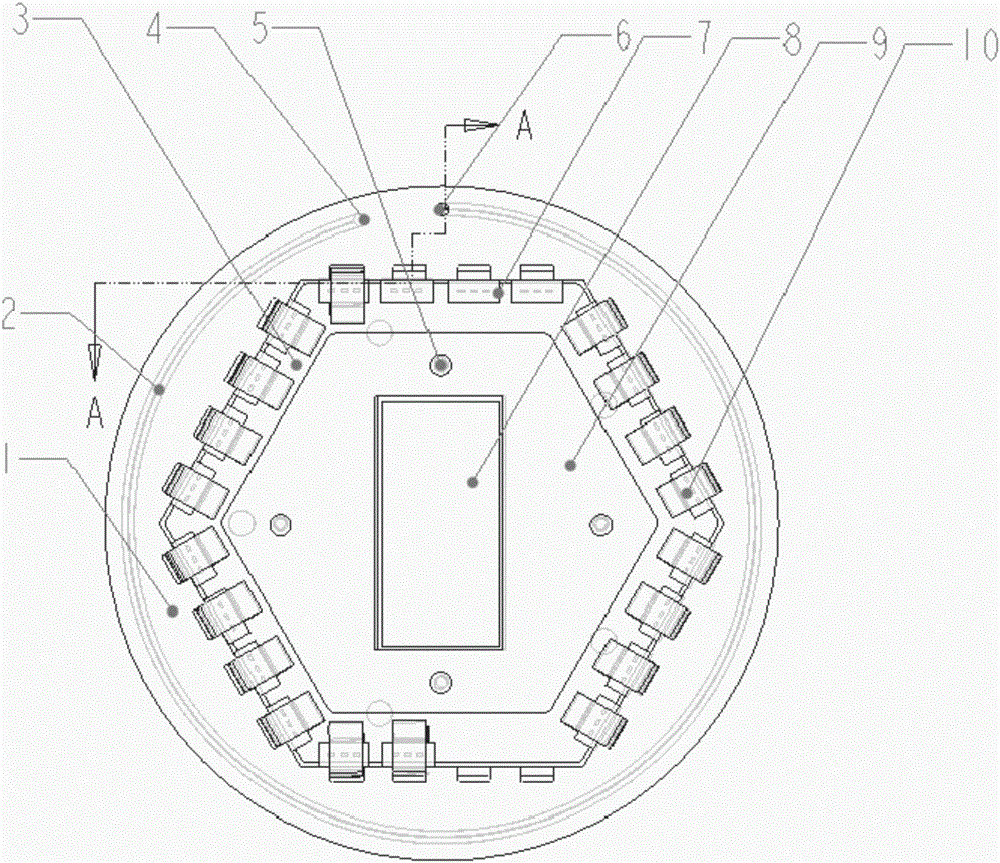

[0027] figure 1 It is an exploded schematic diagram of the highly integrated motor controller of the present invention. figure 2 It is a schematic diagram of the casing of the highly integrated motor controller of the present invention. image 3 It is a schematic diagram of the arrangement structure of the highly integrated motor controller of the present invention. Figure 4 for image 3 A schematic diagram viewed from the A-A direction in . Figure 5 for Figure 4 An enlarged schematic view of part B in .

[0028] Such as figure 1 and figure 2 As shown, the highly integrated motor controller provided by the embodiment of the present invention has a cylindrical structure as a whole and is used to realize the power conversion function, including...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com