Oxygen-doped molybdenum disulfide material and preparation method thereof

A molybdenum disulfide and oxygen doping technology, which is applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., to achieve the effect of large specific surface area and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

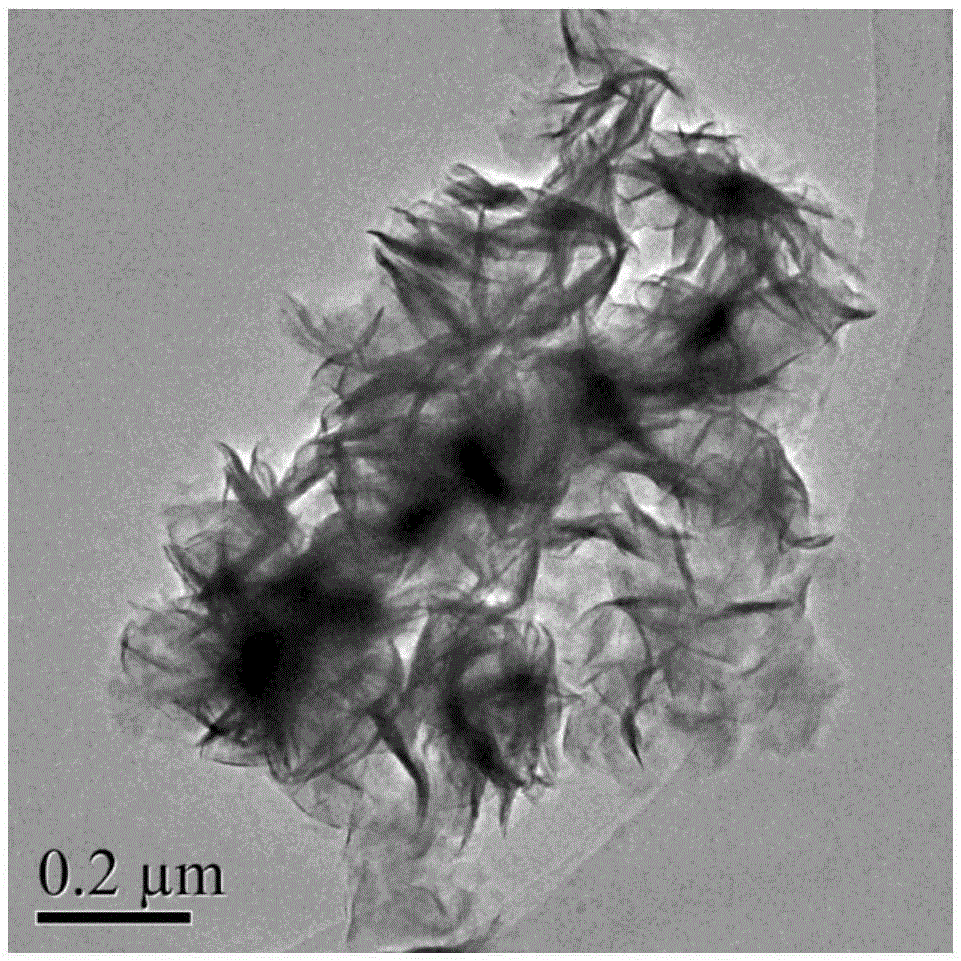

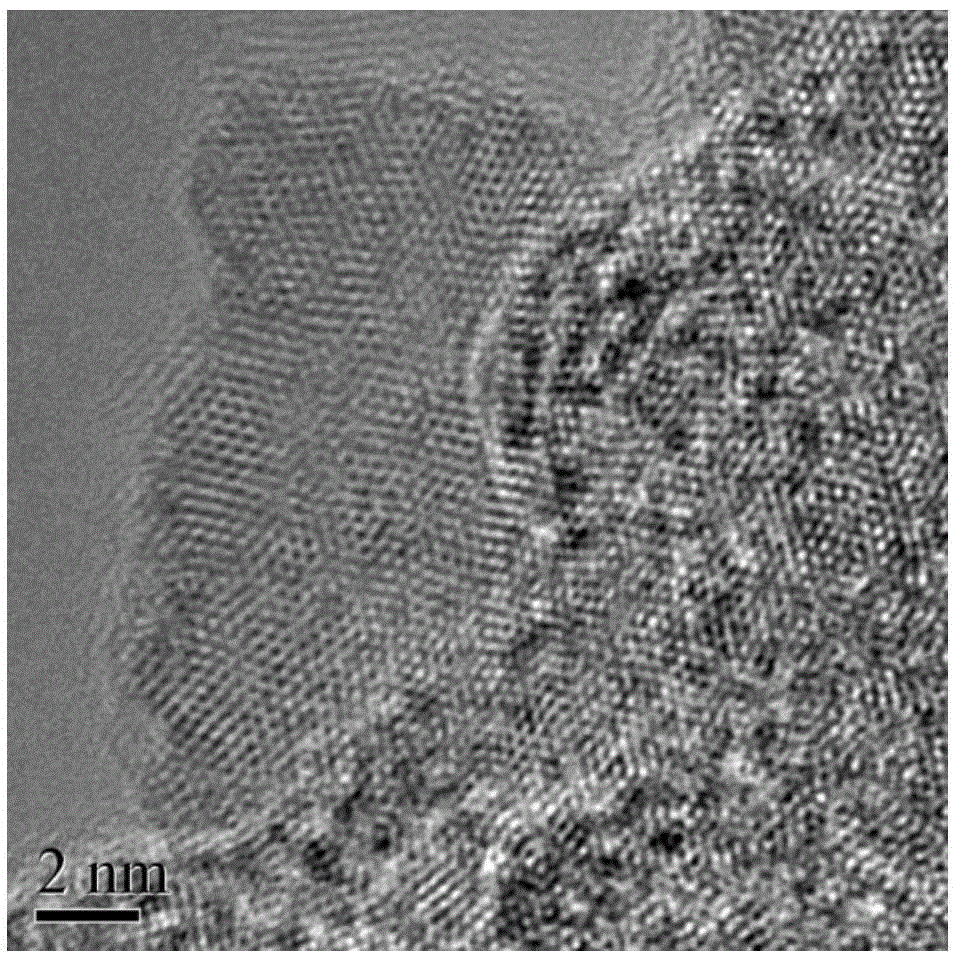

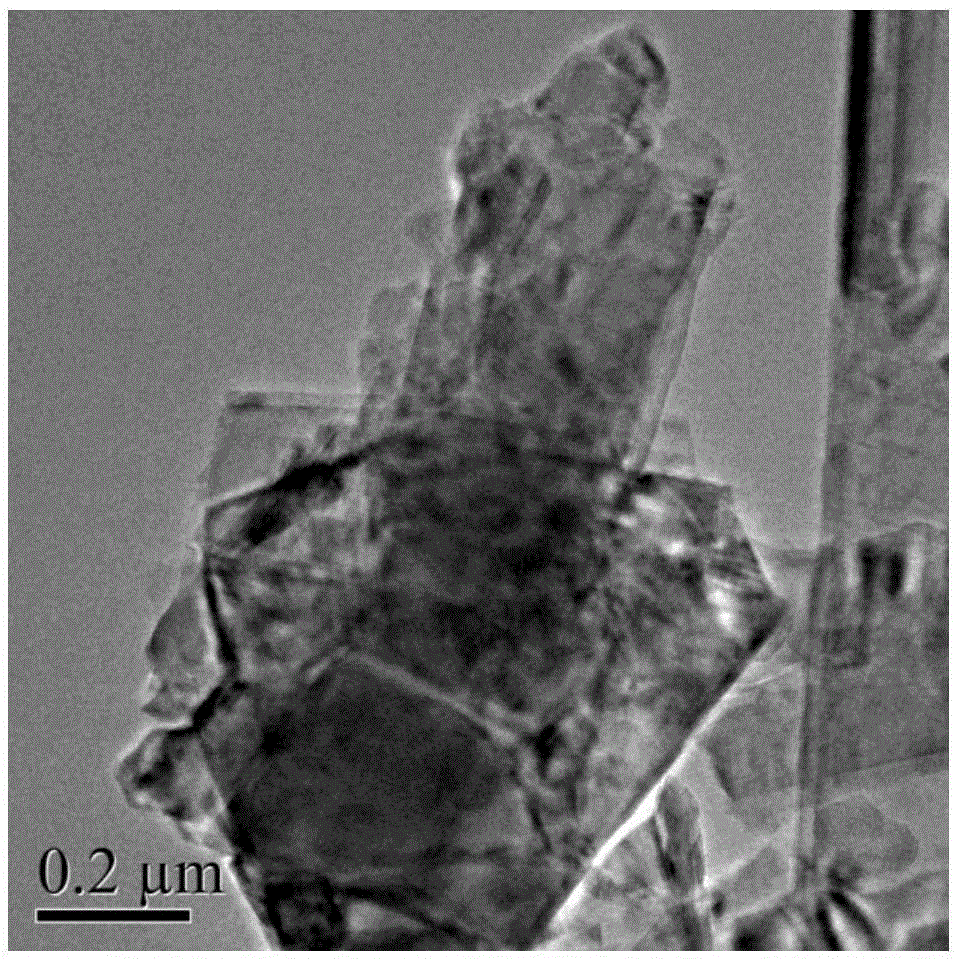

Image

Examples

Embodiment 1

[0024] Use MoO 3 (7mmol) was added as the precursor of molybdenum, ammonium sulfide (21mmol) was added, the volume of the mixture was adjusted to 200mL and pH=10 with deionized water and ammonia water, and the reaction was stirred at 70°C for 2h. After the reaction was completed, it was transferred to a 300mL composite kettle, the gas inside the composite kettle was replaced with nitrogen, 100 mmol of hydrazine hydrate was added, the kettle was sealed, and then hydrothermally synthesized at 170°C for 12 hours. After the reaction is completed, filter, wash the obtained sample with deionized water, and dry it in vacuum at 100°C to obtain the sample, coded as O-MoS 2 (3.0-170-12). Micromeritics ASAP 2010 physical adsorption instrument was used to measure the specific surface area of the sample. Before the test, the sample was vacuum treated at 110 ° C for more than 3 hours to make the vacuum degree reach 10 -6 About torr, and then tested at the temperature of liquid nitrogen ...

Embodiment 2

[0026] Use (NH 4 ) 6 Mo 7 o 24 . 4H 2 O (1 mmol) was added as the precursor of molybdenum, ammonium sulfide (24.5 mmol) was added, the volume of the mixture was adjusted to 200 mL and pH=11 with deionized water and ammonia water, and the reaction was stirred at 70° C. for 2 h. After the reaction was completed, it was transferred to a 300mL composite kettle, and the gas inside the composite kettle was replaced with nitrogen, 100 mmol of hydrazine hydrate was added, the kettle was sealed, and then hydrothermally synthesized at 180°C for 10 hours. After the reaction is completed, filter, wash the obtained sample with deionized water, and dry it in vacuum at 100°C to obtain the sample, coded as O-MoS 2 (3.5-180-10). Micromeritics ASAP 2010 physical adsorption instrument was used to measure the specific surface area of the sample. Before the test, the sample was vacuum treated at 110 ° C for more than 3 hours to make the vacuum degree reach 10 -6 About torr, and then teste...

Embodiment 3

[0028] Use MoO 3 (7mmol) was added as the precursor of molybdenum, ammonium sulfide (26.25mmol) was added, the volume of the mixture was adjusted to 200mL and pH=10 with deionized water and ammonia water, and the reaction was stirred at 80°C for 1h. After the reaction was completed, it was transferred into a 300mL composite kettle, and the gas inside the composite kettle was replaced with nitrogen, 110 mmol of hydrazine hydrate was added, the kettle was sealed, and then hydrothermally synthesized at 180°C for 24 hours. After the reaction is completed, filter, wash the obtained sample with deionized water, and dry it in vacuum at 100°C to obtain the sample, coded as O-MoS 2(3.75-180-24). Micromeritics ASAP 2010 physical adsorption instrument was used to measure the specific surface area of the sample. Before the test, the sample was vacuum treated at 110 ° C for more than 3 hours to make the vacuum degree reach 10 -6 About torr, and then tested at the temperature of liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com