Efficient and controllable desalinated seawater mineralization process

A process and high-efficiency technology, applied in the field of highly efficient and controllable seawater desalination water mineralization process, can solve problems such as the inability to realize efficient utilization of carbon dioxide gas, achieve safe, stable and controllable process operating conditions, increase calcium ions and alkalinity, and efficiently The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

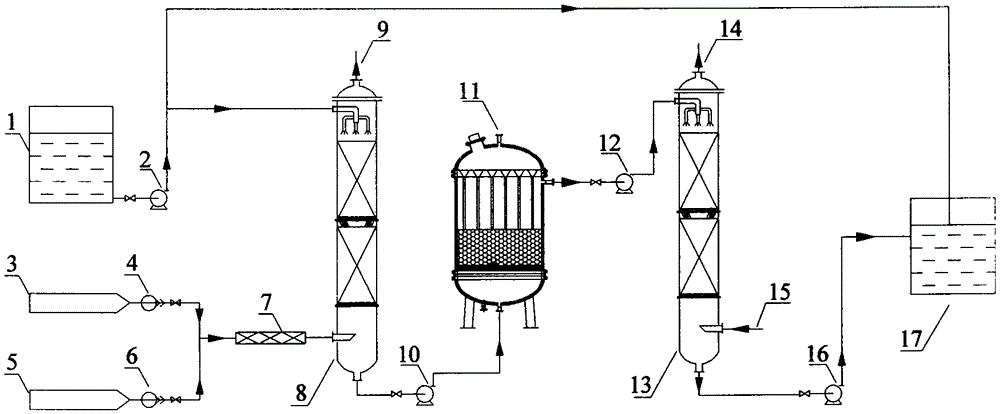

Embodiment 1

[0018] The compressed air produced by the air compression system 5 is fully mixed with the carbon dioxide gas (food grade) from the steel cylinder 3 in the static mixer 7, and the volume ratio is 1:20. The mixed gas enters from the bottom of the absorption tower 8, and the desalinated water in the desalinated water storage tank 1 is transported to the top of the absorption tower through the centrifugal pump 2, and the countercurrent contact is adopted to fully dissolve the carbon dioxide gas. The pH of the acidified water at the bottom of the tower is 5.5. The acidified water flowing out from the bottom of the absorption tower is transported to the bottom of the reactor 11 through the centrifugal pump 10, and passes through the reactor in an upflow manner. The particle size of the limestone filler in the reactor is 0.5mm, and the linear velocity of the rising water flow is 0.0012m / s. The mineralized water overflowing from the reaction kettle passes through the desorption tower...

Embodiment 2

[0020] The compressed air produced by the air compression system 5 is fully mixed with the carbon dioxide gas (food grade) from the cylinder 3 in the static mixer 7, and the volume ratio is 1:10. The mixed gas enters from the bottom of the absorption tower 8, and the desalinated water enters from the top of the absorption tower. Countercurrent contact is adopted to fully dissolve the carbon dioxide gas. The pH of the acidified water at the bottom of the tower is 4. The acidified water flowing out from the bottom of the absorption tower is transported to the bottom of the reactor 11 through the centrifugal pump 10, and passes through the reactor in an upflow manner. The particle size of the limestone filler in the reactor is 2.5mm, and the linear velocity of the rising water flow is 0.002m / s. The mineralized water overflowing from the reaction kettle passes through the desorption tower to remove excess carbon dioxide gas, and the finished mineralized water can be obtained. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com