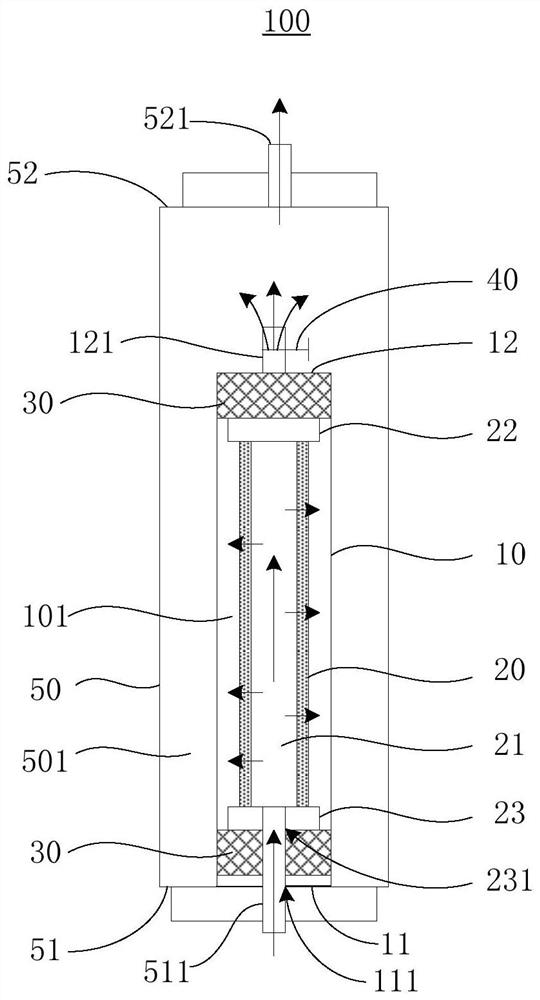

Mineralized filter element based on rock and polymer composite material as well as preparation method and application of mineralized filter element

A technology for mineralizing filter elements and polymers, which can be used in chemical instruments and methods, filtration treatment, added material water/sewage treatment, etc., and can solve problems such as low mineral content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

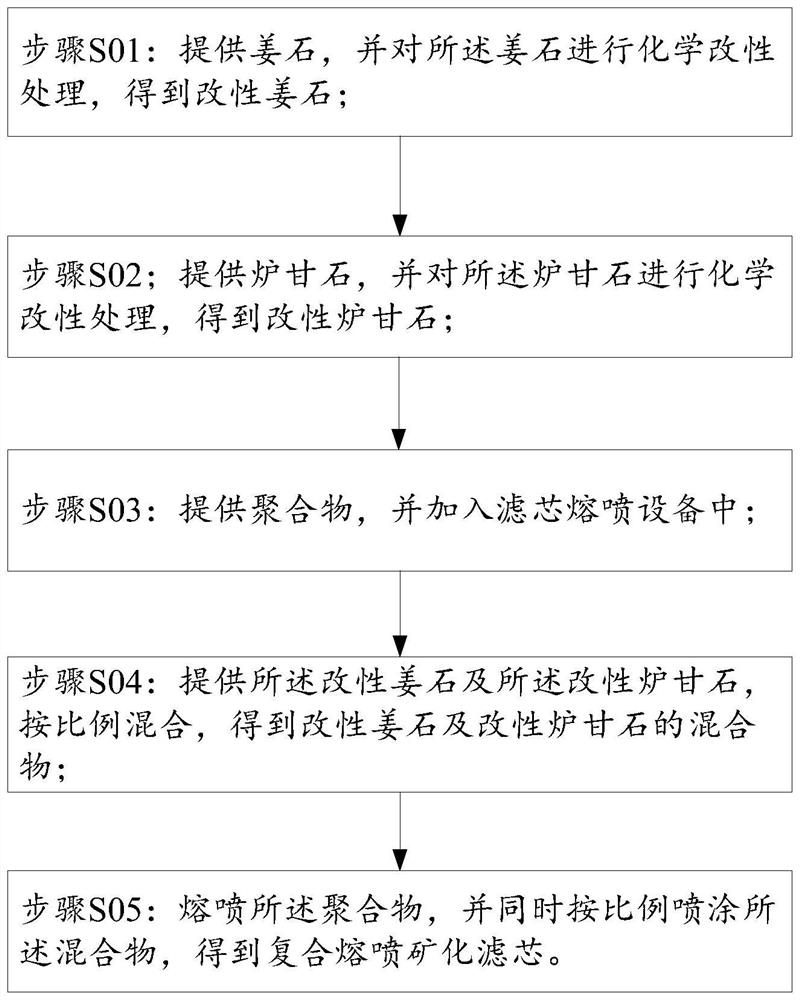

[0066] see figure 2 , the embodiment of the present application also provides a preparation method of the mineralization filter element 20, comprising the following steps:

[0067] Step S01: providing ginger stone, and chemically modifying the ginger stone to obtain modified ginger stone;

[0068] Step S02: providing calamine, and chemically modifying the calamine to obtain modified calamine;

[0069] Step S03: Provide a polymer and add it to the filter element melt blown equipment;

[0070] Step S04: providing the modified ginger stone and the modified calamine, and mixing them in proportion to obtain a mixture of modified ginger stone and modified calamine;

[0071] Step S05: melt-blowing the polymer, and simultaneously spraying the mixture in proportion to obtain a composite melt-blown mineralization filter element 20 .

[0072] In the step S01:

[0073] The method for carrying out chemical modification treatment to described ginger stone comprises the steps:

[0074]...

Embodiment 1

[0127] The mineralized filter core 20 of the filter 100 of the present embodiment is made by the following method:

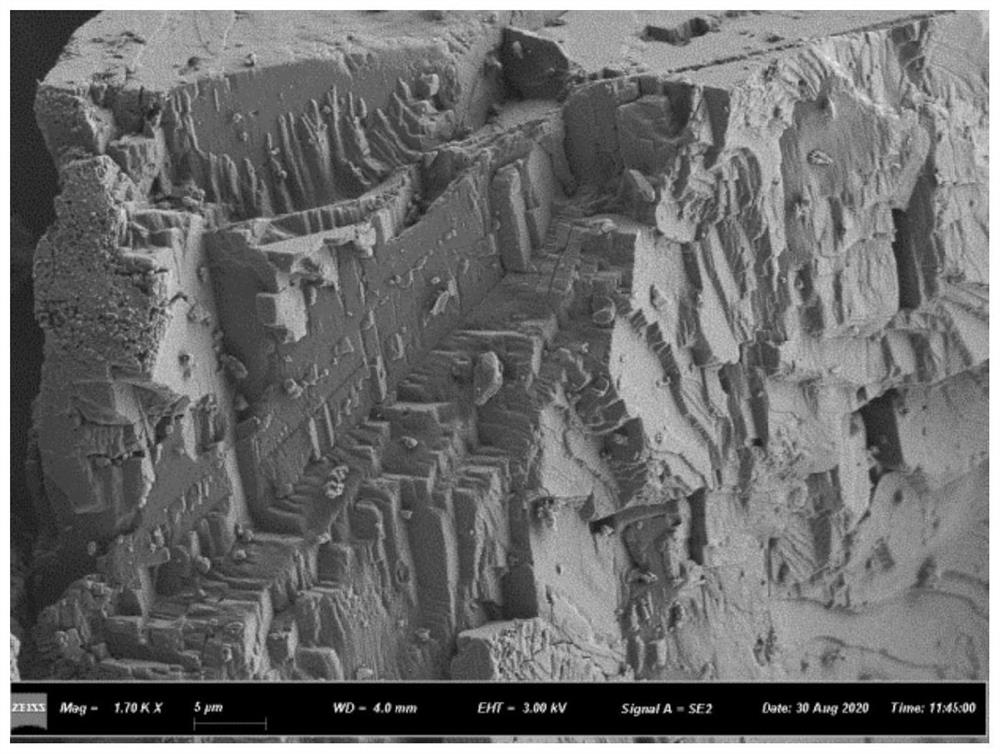

[0128] Preparation of modified ginger stone

[0129] Take 10kg of natural ginger stone and ultrasonically treat it with deionized water to obtain ginger stone powder with a particle size of 35-100 mesh, and then calcinate it at 900°C for 2 hours, then add it to a mixture containing 0.08kg citric acid and 2L deionized water according to the solid-liquid ratio of 5:1. In the solution of ionized water, take out after cooling, then filter and dry after washing with deionized water, obtain modified ginger stone;

[0130] Preparation of modified calamine

[0131] 1 kg of natural calamine was ultrasonically treated with deionized water to obtain calamine powder with a particle size of 35-100 mesh, and then calcined in an argon atmosphere at 750 ° C for 1 h, and then quickly put into 5 L of 0.1 mol / L dilute In hydrochloric acid, after cooling, add 5L of NaOH solution ...

Embodiment 2

[0139] This embodiment is basically the same as that of Embodiment 1, except that 20 g of modified ginger stone and 5 g of modified calamine are used to prepare the mineralized filter element 20 of the filter 100 of this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com