Preparation method, product and application of core-shell catalyst containing hβ molecular sieve

A technology of core-shell catalysts and β molecular sieves, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of insufficient hydrogenation capacity, catalyst deactivation, and carbon deposition of methanol synthesis catalysts, and achieve easy Industrial scale-up, high catalytic activity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 prepares CuO / ZnO catalyst

[0042] 1) Accurately weigh Cu(NO 3 ) 2 ·3H 2 O 14.496g, Zn(NO 3 ) 2 ·6H 2 O 17.8494g, dissolved in 300mL deionized water to form a mixed solution, weighed 30g anhydrous Na 2 CO 3 , dissolved in 300mL deionized water to form Na 2 CO 3solution; slowly drop the mixed solution of copper nitrate and zinc nitrate and sodium carbonate solution into 300ml deionized water and stir, control the pH value to be stable at 8.6, and control the co-precipitation temperature in a constant temperature water bath to 60°C;

[0043] 2) aging the product obtained in step 1) at room temperature for 12 hours;

[0044] 3) Suction filter the product obtained in step 2) with a vacuum filter, wash the filter cake with deionized water, and then perform suction filtration for a total of 5 times to determine that the precipitate is washed to neutral;

[0045] 4) Dry in an oven at 120°C for 6 hours;

[0046] 5) Finally, the CuO / ZnO catalyst was obtai...

Embodiment 2

[0047] Embodiment 2 prepares Hβ molecular sieve

[0048] 1) Accurately weigh TEOS 16.2903g, TEAOH 15.9955g, aluminum isopropoxide 0.3275g, H 2 O3.5672g, KNO 3 0.149g mixing and stirring to prepare synthetic liquid;

[0049] 2) Place the mixed solution obtained in step 1) in a homogeneous hydrothermal synthesis reactor, and conduct hydrothermal crystallization at 155°C and 2 rpm for 72 hours;

[0050] 3) Wash the crystals obtained in step 2) and put them into an oven to dry at 120° C. for 12 hours;

[0051] 4) The product obtained in step 3) was placed in a muffle furnace and calcined at 550° C. for 5 hours to obtain a sodium molecular sieve.

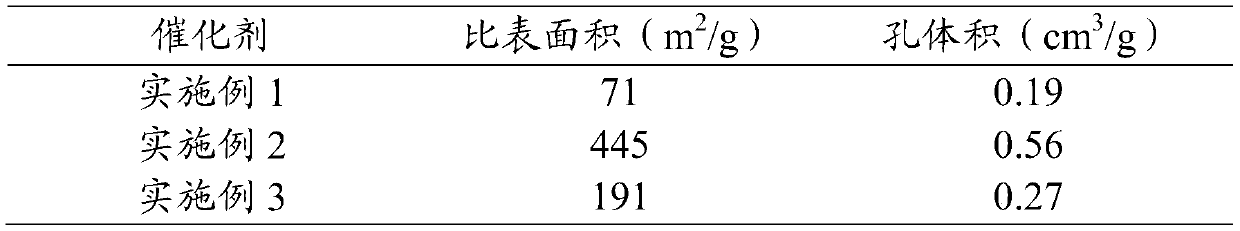

[0052] 5) Put the sodium-type molecular sieve obtained in step 4) into a 1mol / L ammonium nitrate solution, perform ion exchange at 80° C. for 6 hours, dry and calcinate again to obtain the Hβ molecular sieve. N of Hβ molecular sieve 2 The adsorption properties are characterized in Table 1.

Embodiment 3~5

[0053] Embodiment 3~5 prepares the core-shell catalyst containing Hβ molecular sieve

[0054] The CuO / ZnO catalyst prepared in Example 1 and the Hβ molecular sieve prepared in Example 2 were used. According to the requirement of loading capacity, the mass ratios of CuO / ZnO catalyst and Hβ molecular sieve in Examples 3-5 were 2:1, 4, respectively. :1 and 8:1. Take a certain amount of silica sol (30wt%) to soak the CuO / ZnO catalyst for 5 minutes, take it out and pour it into a round-bottomed flask equipped with Hβ molecular sieves, and shake the molecular sieves to adhere to the surface of the CuO / ZnO catalyst to form a core-shell structure. The catalyst was taken out, dried at 120°C for 6h, and calcined at 400°C for 2h to obtain a core-shell catalyst containing Hβ molecular sieve, whose N 2 The characterization of the adsorption properties is shown in Table 1

[0055] Table 1: N of different catalysts 2 Adsorption properties

[0056]

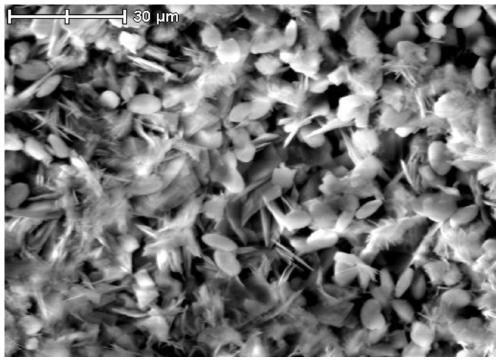

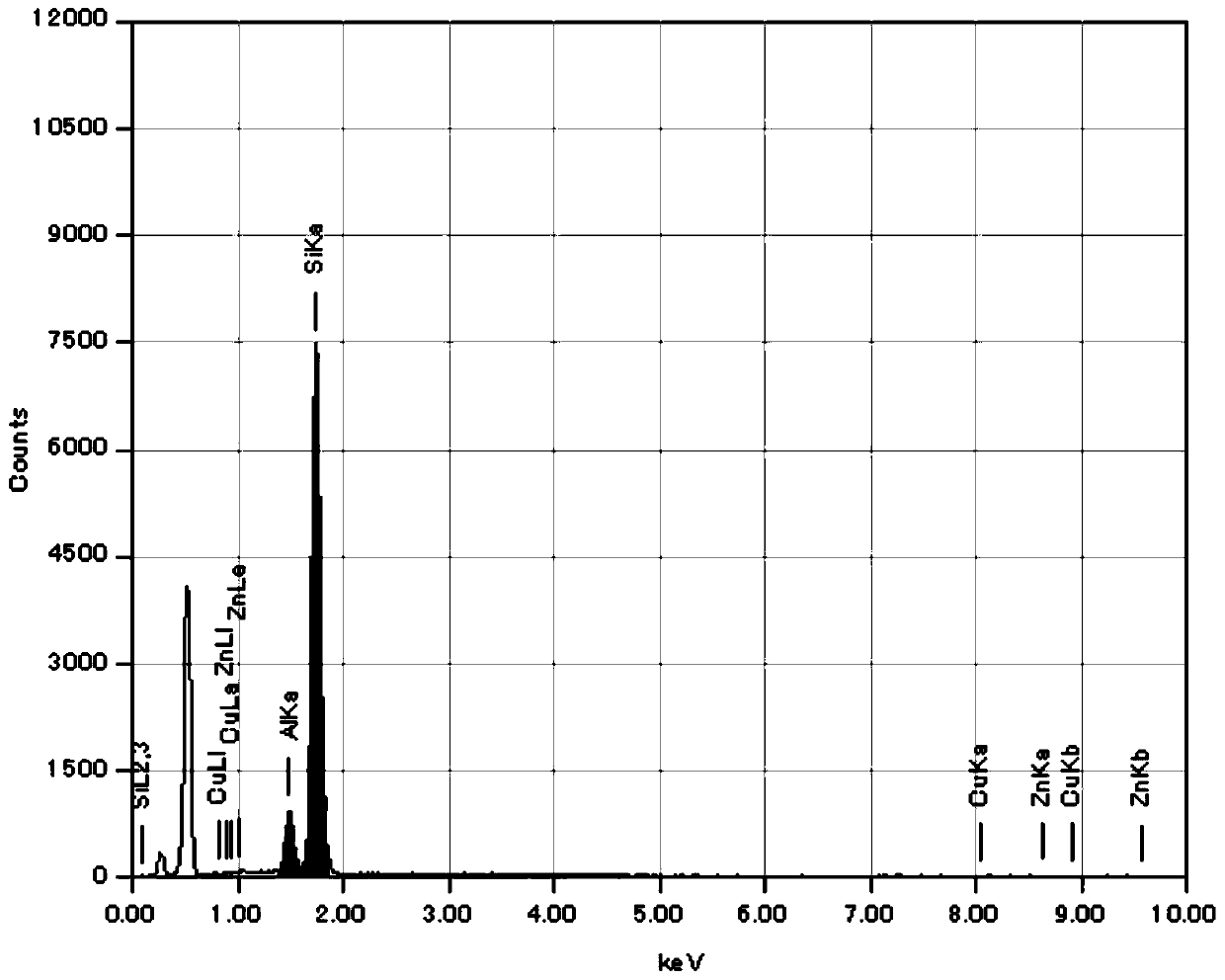

[0057] The core-shell catalyst cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com