Circulating marine aquaculture system based on membrane method microalgae cultivation

A seawater aquaculture system and a technology for culturing microalgae, which are applied in the field of circulating seawater aquaculture, can solve the problems of reducing water consumption, and the antifouling effect of aquaculture ponds needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

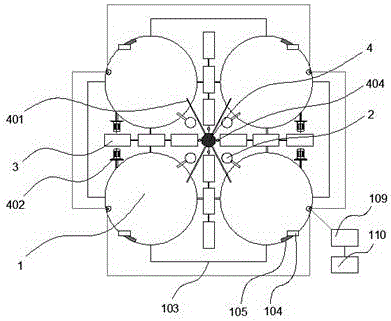

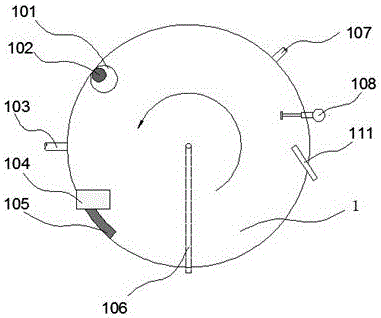

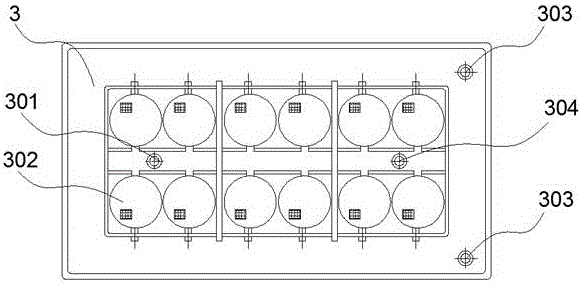

[0020] Such as Figure 1~5 As shown, a circulating seawater culture system based on membrane microalgae cultivation includes a culture tank 1, a foam separation device 2, a culture tank 3 and a water collector 4. The culture tank 1 is provided with a rubber tube 101, and the bottom of the rubber tube 101 is connected to the The bottom of the breeding pond 1 is sealed and connected, the top of the rubber tube 101 is at the same height as the breeding pond 1, the rubber tube 101 is provided with an optical fiber 102, the optical fiber 102 is connected with the distributed optical fiber temperature thermometer 109, and the distributed optical fiber temperature thermometer 109 is connected to the set The control room 110 is connected, and the distributed optical fiber temperature thermometer 109 is connected with an alarm. 1 are connected by a connecting pipe 103, the angle between the return pipe 107 and the joint of the culture pond 1 is 5-70°, the bottom of the culture pond 1 i...

Embodiment 2

[0025] Such as Figure 1~5As shown, a circulating seawater culture system based on membrane microalgae cultivation includes a culture tank 1, a foam separation device 2, a culture tank 3 and a water collector 4. The culture tank 1 is provided with a rubber tube 101, and the bottom of the rubber tube 101 is connected to the The bottom of the breeding pond 1 is sealed and connected, the top of the rubber tube 101 is at the same height as the breeding pond 1, the rubber tube 101 is provided with an optical fiber 102, the optical fiber 102 is connected with the distributed optical fiber temperature thermometer 109, and the distributed optical fiber temperature thermometer 109 is connected to the set The control room 110 is connected, and the distributed optical fiber temperature thermometer 109 is connected with an alarm. 1 are connected by a connecting pipe 103, the angle between the return pipe 107 and the joint of the culture pond 1 is preferably 45°, the bottom of the culture ...

Embodiment 3

[0030] Such as Figure 1~5 As shown, a circulating seawater culture system based on membrane microalgae cultivation is provided with four culture ponds 1, the culture ponds 1 are circular, and the diameter of the top of the culture pond 1 is greater than the diameter of the bottom, which is conducive to the concentration of pollutants at the bottom. 1 are connected by a connecting pipe 103 to reach the equal water level of each culture pond 1, the culture boxes 3 are connected to each other and connected to the water collector 4 through a water pump 404, and the culture boxes 3 are arranged at the gap between the culture ponds 1 and connected The breeding box 3 is cross-shaped, and the circulation pipe 401 that the water collector 4 is provided with is connected with the circulation pipe 107 that the cultivation pond 1 is provided with, and the cultivation pond 1 is connected with the cultivation case 3 through the circulation pipe 107 and the return pipe 111, so as to reach th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com