Preparation method and application of slow release algicide

A slow-release algicide, sodium alginate technology, applied in herbicides and algicides, botanical equipment and methods, applications, etc., can solve the problem of high local concentration in the use area, and achieve good ecological safety and operation. Simple, controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

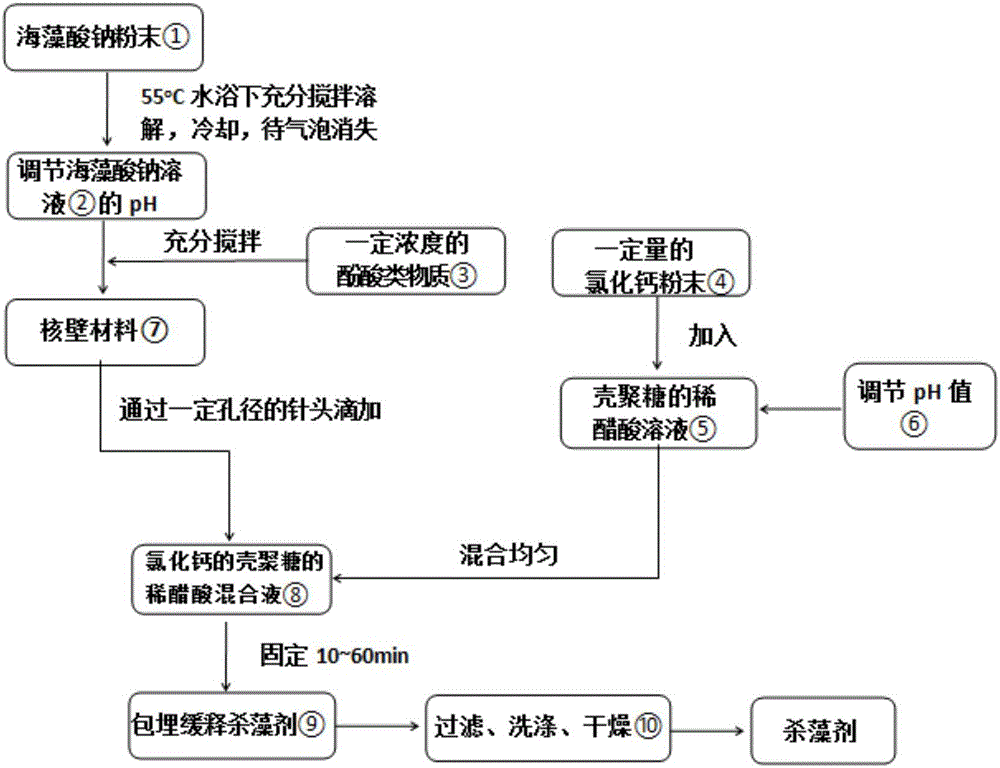

[0039] according to figure 1 As can be seen, a kind of preparation method of slow release type algicide, its step is:

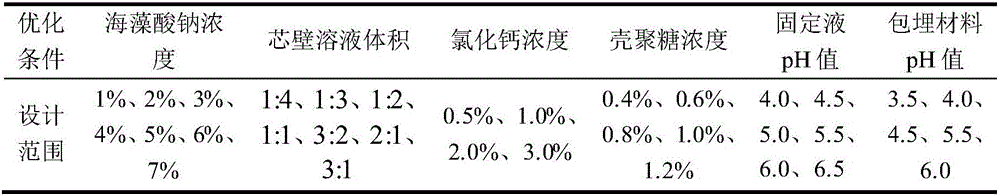

[0040] (1) Weigh a certain amount of sodium alginate powder ① and dissolve it in deionized water, and dissolve it in a constant temperature water bath at 50 or 52 or 54 or 56 or 58 or 60°C to obtain a concentration of 1%, 2%, or 3% by mass. %, 4%, 5%, 6% and 7% of 20ml sodium alginate colloidal solutions of different concentrations, and then use 0.1-1mol / L hydrochloric acid solution to adjust the pH value of the sodium alginate solution ② to about 5.5, After the sodium alginate solution is cooled to about 20°C and the bubbles disappear, it is ready for use;

[0041] (2) Weigh 0.1g of phenolic acid allelochemical powder ③, dissolve it in deionized water and dilute to 100mL, mix well and prepare a solution of phenolic allelochemical with a concentration of 1.0mg / mL as the algicide Core substance (the addition amount of specific core phenolic acid substances w...

Embodiment 2

[0048] According to the optimized preparation conditions after screening, three different slow-release algastatic agents were prepared according to the order of embedding methods:

[0049] (1) The first one is to add pyrogallic acid solution, a representative substance of phenolic acids, into sodium alginate solution, and then directly drop the mixed homogeneous solution into calcium chloride solution for 20 or 25 or 30 or 35 or 40min, filter, wash and dry;

[0050] (2) The second is to pre-drop the uniform mixture of pyrogallic acid solution and sodium alginate solution, which is the representative substance of phenolic acids, into the calcium chloride solution drop by drop to fix, then filter, wash, and then add the above Put the washed embedding into chitosan dilute acetic acid solution for fixation for 20 or 24 or 28 or 32 or 36 or 40 min, filter, wash, and dry;

[0051] (3) The last one is to drop the uniform mixed solution of pyrogallic acid solution and sodium alginate...

Embodiment 3

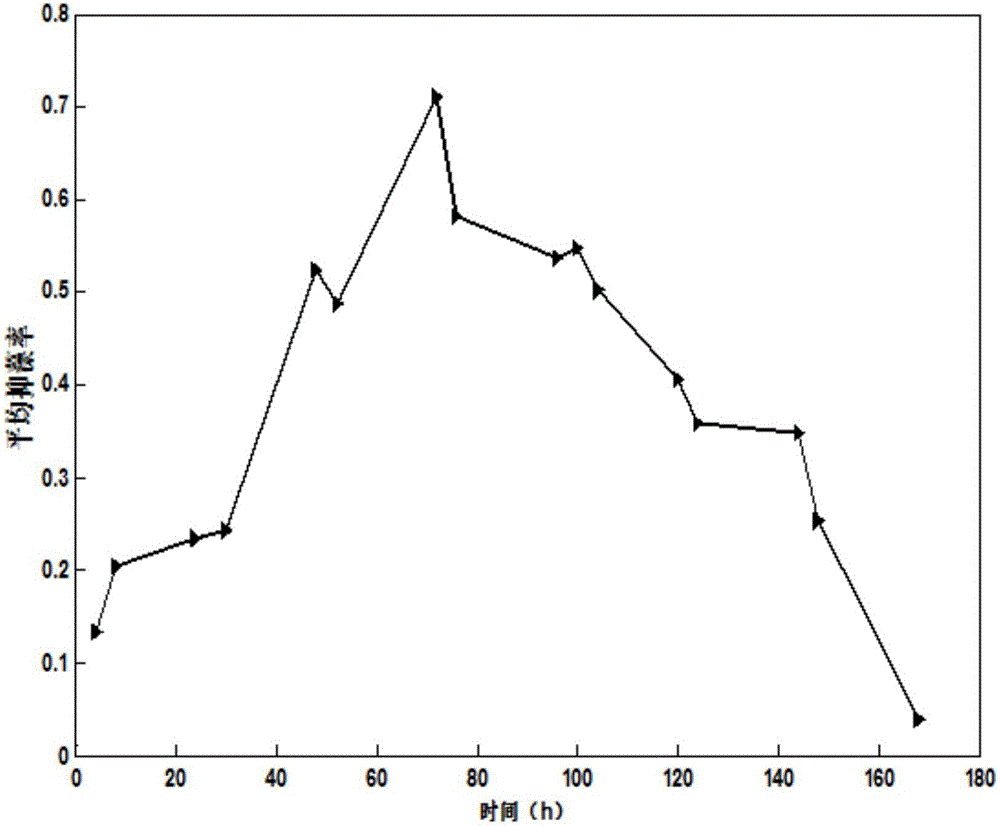

[0057] A kind of slow-release type algicide is used in the application of the algicide in the dominant species of water bloom—Microcystis aeruginosa, and the steps are:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com