Bactericidal composition containing quinoline copper and kasugamycin

A technology of kasugamycin and copper quinoline, which is applied in the field of compound pesticides and can solve problems such as the generation of disease resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

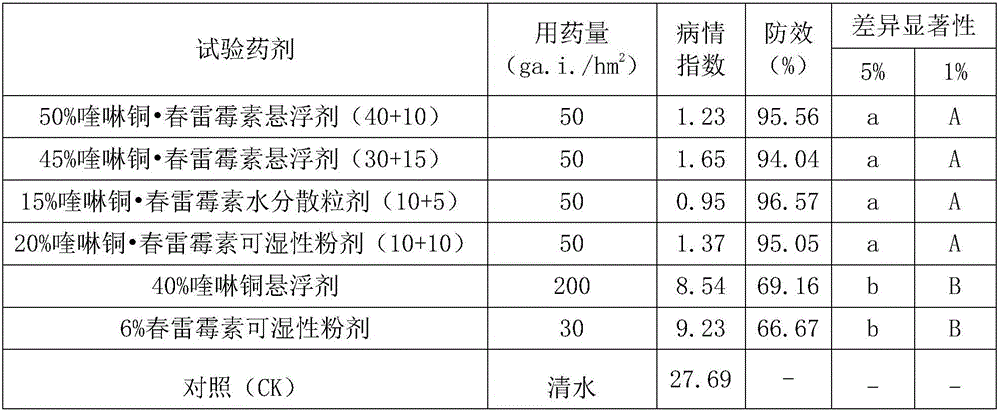

Image

Examples

Embodiment 1

[0030] Weigh 30% quinoline copper, 15% kasugamycin, 4% emulsifier Nongru 700# (common name: alkylphenol formaldehyde resin polyoxyethylene ether), 5% dispersant TERSPERSE 2020 (produced by Huntsman, USA) ), 2% wetting agent TERSPERSE2500 (produced by Huntsman, USA), 1.5% viscosity modifier xanthan gum, 5% antifreeze ethylene glycol, 0.5% silicone defoamer (trade name: s-29 Nanjing Si New Applied Chemicals Company), the balance is deionized water.

[0031] The above-mentioned raw materials are processed through the processes of mixing, pre-crushing, crushing with a sand mill, mixing and blending, and packaging. Different parameter equipment can be selected according to the actual production for the pre-crushing and mixing process. The sand mill pulverization process of the suspending agent in this embodiment uses four sand mills, multi-stage series, using fine sand and coarse sand, the first sander is fully loaded with coarse sand, and the second sander is filled with 2 / 3 coar...

Embodiment 2

[0033] Weigh 40% copper quinoline, 10% kasugamycin, 3% TERSPERSE 4894 (produced by Huntsman, U.S.), 2% TERSPERSE 2500 (produced by Huntsman, U.S.), 4% diffusing agent NNO, 1.5% bentonite, 1% xanthan gum, 8% ethylene glycol, 0.5% formaldehyde, 0.5% silicone defoamer (trade name: s-29 produced by Nanjing Sixin Applied Chemicals Co., Ltd.), and deionized water are added to 100% by weight.

[0034] The above-mentioned raw materials are processed through the processes of mixing, pre-crushing, crushing with a sand mill, mixing and blending, and packaging. Different parameter equipment can be selected according to the actual production for the pre-crushing and mixing process. The sand mill pulverization process of the suspending agent in this embodiment uses four sand mills, multi-stage series, using fine sand and coarse sand, the first sander is fully loaded with coarse sand, and the second sander is filled with 2 / 3 coarse sand. Sand and 1 / 3 fine sand, the third sand mill is filled...

Embodiment 3

[0036] Take by weighing 25% copper quinoline, 15% kasugamycin, 3% TERSPERSE 2700 (polycarboxylate, produced by Huntsman, U.S.), 3% sodium lignosulfonate, 1% pull open powder BX (dibutyl sodium naphthalenesulfonate), 1% sodium lauryl sulfate (K-12), 2% PVA (molecular weight 2000), 2% polyvinylpyrrolidone, 0.5% white carbon black, and kaolin added to 100% by weight. The above-mentioned raw materials are prepared through the conventional method for preparing water-dispersible granules, ie, mixing, ultrafine airflow pulverization, mixing, and granulating steps to prepare water-dispersible granules with 40% copper quinoline·kasugamycin as the active ingredient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com