Production method of whey polypeptide beverage

A production method and technology of whey peptides, applied in milk substitutes, dairy products, applications, etc., can solve problems such as waste of resources, environmental pollution, etc., and achieve the effects of acidic taste, wide range of people, and easier digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

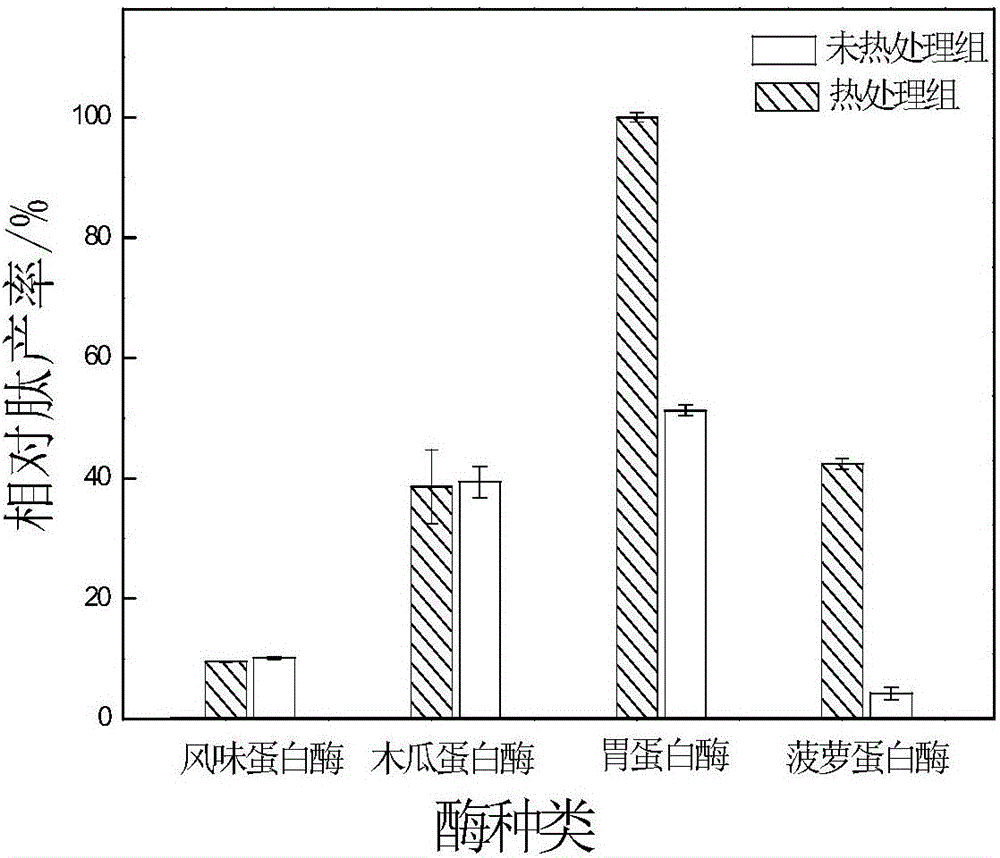

[0029] Example 1 Screening of Key Enzyme System of Whey Polypeptide Beverage

[0030] 1. Heat treatment: Soybean whey wastewater was heat-treated at 95°C for 15 minutes to moderately denature the protein to ensure maximum enzymatic hydrolysis of the protein.

[0031] 2. Enzymolysis: The product of step 1 is subjected to enzymolysis, the amount of enzyme added is 1000U / g soybean whey protein, hydrolyzed at 37°C for 30min, and the enzymes are flavor protease, papain, pepsin and bromelain.

[0032] 3. Enzyme inactivation and sterilization: the product of step 2 was treated at 95°C for 10 minutes.

[0033] figure 1 It shows that the hydrolysis effect of pepsin is obviously higher than that of the other three enzymes, and the peptide yield of the heat treatment group is greater. Therefore, it is determined that the soybean whey wastewater should be heat-treated first, and then enzymatically hydrolyzed with pepsin.

Embodiment 2

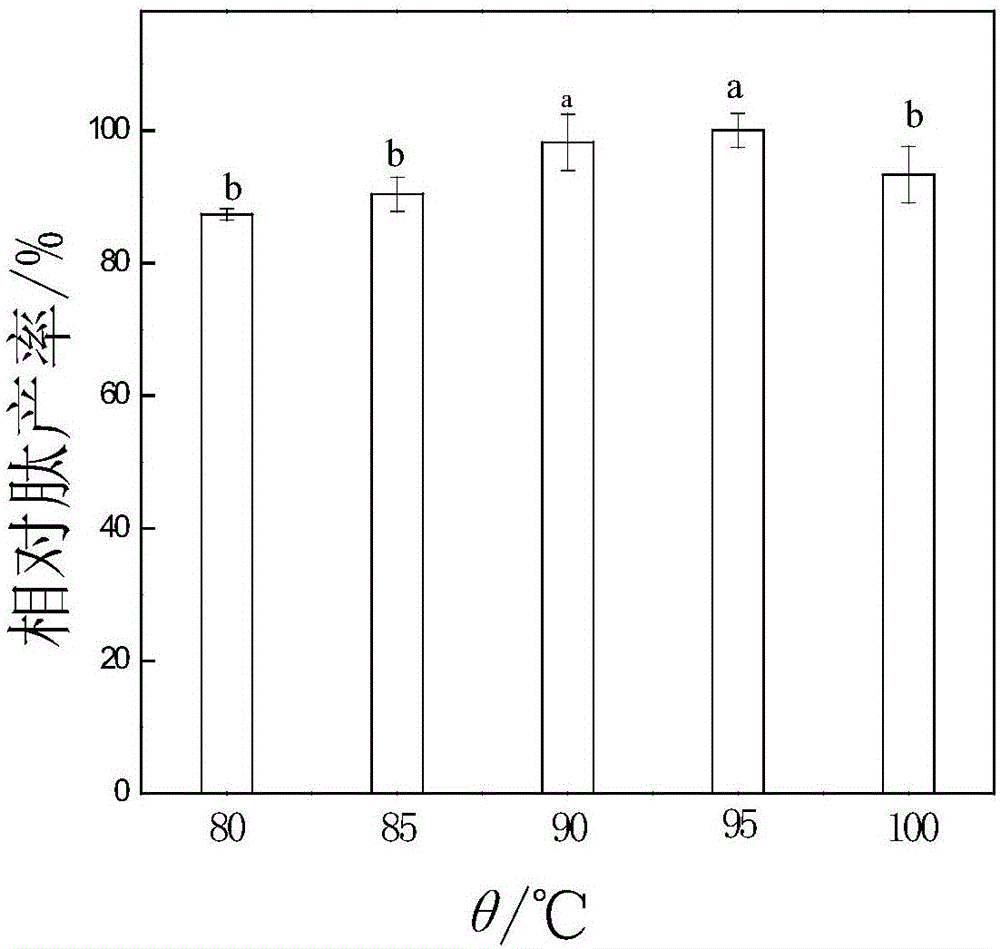

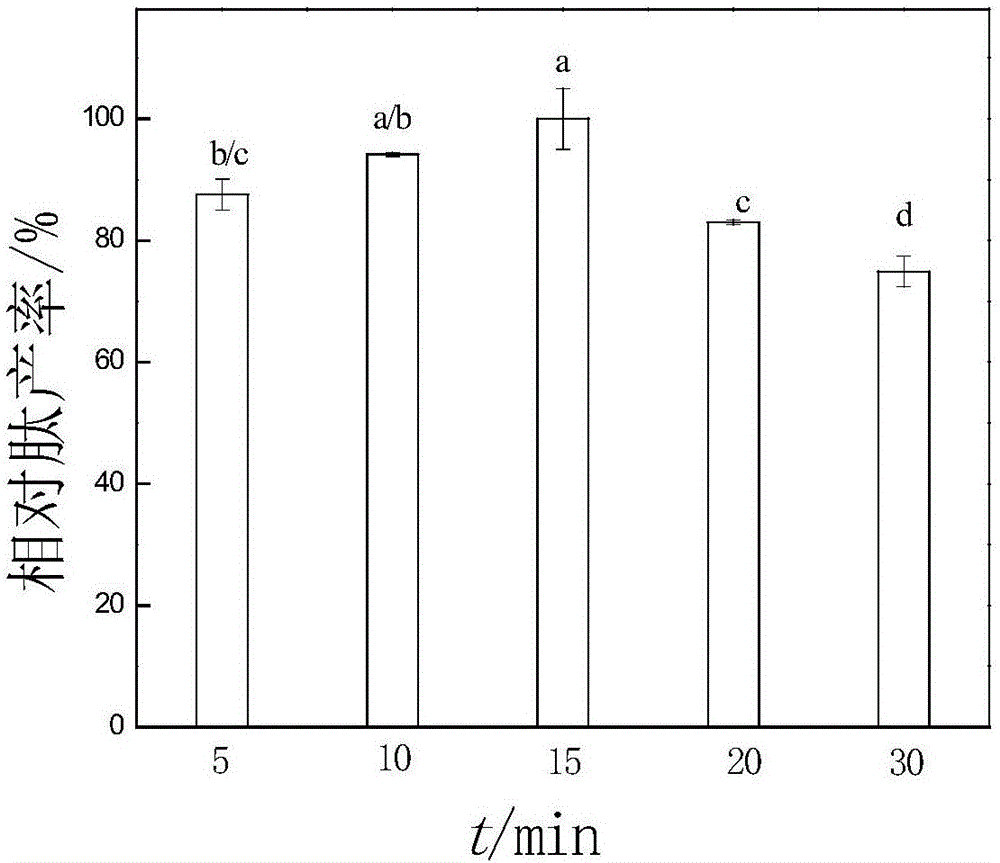

[0034] Example 2 Effects of Different Heat Treatment Conditions on the Enzymolysis Effect of Whey Polypeptide Beverage

[0035] 1. Heat treatment: The heat treatment temperature is 80°C, 85°C, 90°C, 95°C, and 100°C for heat treatment, and the heat treatment time is 5min, 10min, 15min, 20min, and 30min.

[0036] 2. Enzymolysis: The product of step 1 was subjected to enzymolysis, and was hydrolyzed with pepsin (1000 U / g soybean whey protein) at 37° C. for 30 minutes.

[0037] 3. Enzyme inactivation and sterilization: the product of step 2 was treated at 95°C for 10 minutes.

[0038] Depend on figure 2 It can be seen that the peptide yield increases with the increase of heat treatment temperature at 80-90°C, reaches the maximum at 95°C, and decreases with the increase of heat treatment temperature after 95°C, indicating that the heat treatment temperature is too high, which will cause some Excessive protein denaturation is not conducive to hydrolysis. The effect of heat treat...

Embodiment 3

[0040] Example 3 Effects of Different Enzymolysis Temperatures on the Enzymolysis Effect of Whey Polypeptide Beverage

[0041] 1. Heat treatment: Heat treatment at 95°C for 15 minutes to moderately denature the protein to ensure maximum enzymatic hydrolysis of the protein.

[0042] 2. Enzymatic hydrolysis: the product of step 1 was subjected to enzymatic hydrolysis with pepsin (1000 U / g soybean whey protein) at 36°C, 37°C, 38°C, 39°C, and 40°C for 30 minutes respectively.

[0043] 3. Enzyme inactivation and sterilization: the product of step 2 was treated at 95°C for 10 minutes.

[0044] Figure 4 It showed that when the enzymatic hydrolysis time, the initial pH of the reaction and the amount of enzyme added were constant, 38-40°C had no significant effect on the peptide yield, but there were significant differences between 36°C and 37°C and other groups, and the peptide yield at 37°C The highest rate is determined as the suitable hydrolysis temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com