Harm-reducing cigarette filter additive and filter preparation method

An additive and technology for cigarettes, applied in the fields of e-liquid filter elements, applications, tobacco, etc., can solve the problems such as the unseen hazard index of cigarettes, and achieve the effects of reducing spicy stimulation, reducing respiratory diseases, and reducing hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

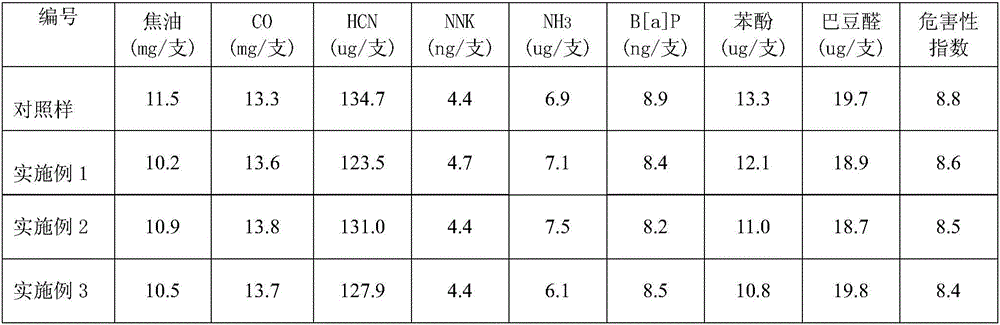

Embodiment 1

[0028] Spray 10 parts by weight of polyethylene glycol 200:passion fruit extract (20:1 weight ratio) mixed solution on the 100 parts by weight of cellulose acetate tow that has been loosened with a constant flow pump, according to the requirements of the cigarette filter production process , roll the cellulose acetate tow coated with the mixed solution of polyethylene glycol 200 and passion fruit extract with a filter tip forming machine to make a filter tip for cigarettes, and roll it into cigarette sticks. Sealed and stored for 24 hours, determine the contents of tar, carbon monoxide, nicotine, hydrocyanic acid, nitrosamine (NNK), ammonia, benzo[α]pyrene, phenol, and crotonaldehyde in cigarette smoke according to national or industry standard methods . The results show that: compared with the control cigarette, the reduction rate of carbon monoxide release in the smoke of the test cigarette is -2.3%, the reduction rate of hydrogen cyanide (HCN) release is 8.3%, the reduction...

Embodiment 2

[0030] Spray 10 parts by weight of polyethylene glycol 200:passion fruit extract (15:1 weight ratio) mixed solution on the 100 parts by weight of cellulose acetate tow that has been loosened with a constant flow pump, according to the requirements of the cigarette filter production process , roll the cellulose acetate tow coated with the mixed solution of polyethylene glycol 200 and passion fruit extract with a filter tip forming machine to make a filter tip for cigarettes, and roll it into cigarette sticks. Sealed and stored for 24 hours, determine the contents of tar, carbon monoxide, nicotine, hydrocyanic acid, nitrosamine (NNK), ammonia, benzo[α]pyrene, phenol, and crotonaldehyde in cigarette smoke according to national or industry standard methods . The results showed that: compared with the control cigarette, the reduction rate of carbon monoxide release in the smoke of the test cigarette was -3.8%, the reduction rate of hydrogen cyanide (HCN) release was 2.7%, the reduc...

Embodiment 3

[0032] Spray 10 parts by weight of polyethylene glycol 200:passion fruit extract (10:1 weight ratio) on the 100 parts by weight of the cellulose acetate tow of opening with a constant flow pump, press the cigarette filter production and processing technology requirement, use The filter tip forming machine rolls the cellulose acetate tow coated with the mixed solution of polyethylene glycol 200 and passion fruit extract into a filter tip for cigarettes, and rolls it into cigarette sticks. Sealed and stored for 24 hours, determine the contents of tar, carbon monoxide, nicotine, hydrocyanic acid, nitrosamine (NNK), ammonia, benzo[α]pyrene, phenol, and crotonaldehyde in cigarette smoke according to national or industry standard methods . The results showed that: compared with the control cigarettes, the reduction rate of carbon monoxide release in the smoke of the test cigarette was -3.0%, the reduction rate of hydrogen cyanide (HCN) release was 5.0%, the reduction rate of nitrosa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com