Manufacturing method of atlas and axis titanium alloy prosthesis

A manufacturing method, titanium alloy technology, applied in the direction of prosthesis, additive manufacturing, manufacturing tools, etc., can solve the problems of stress shielding, large difference, etc., and achieve the possible effect of reducing the elastic modulus and reducing the phenomenon of stress shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Attached below Figures 1 to 9 And specific embodiments, the present invention is further specifically described in detail.

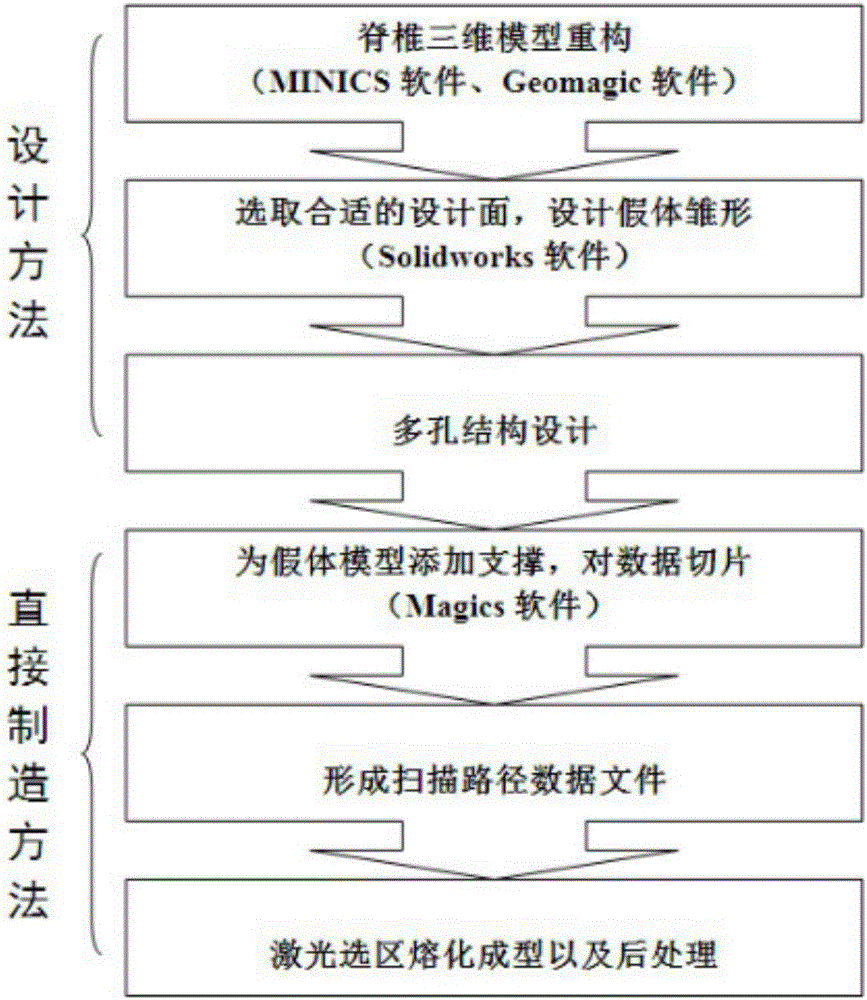

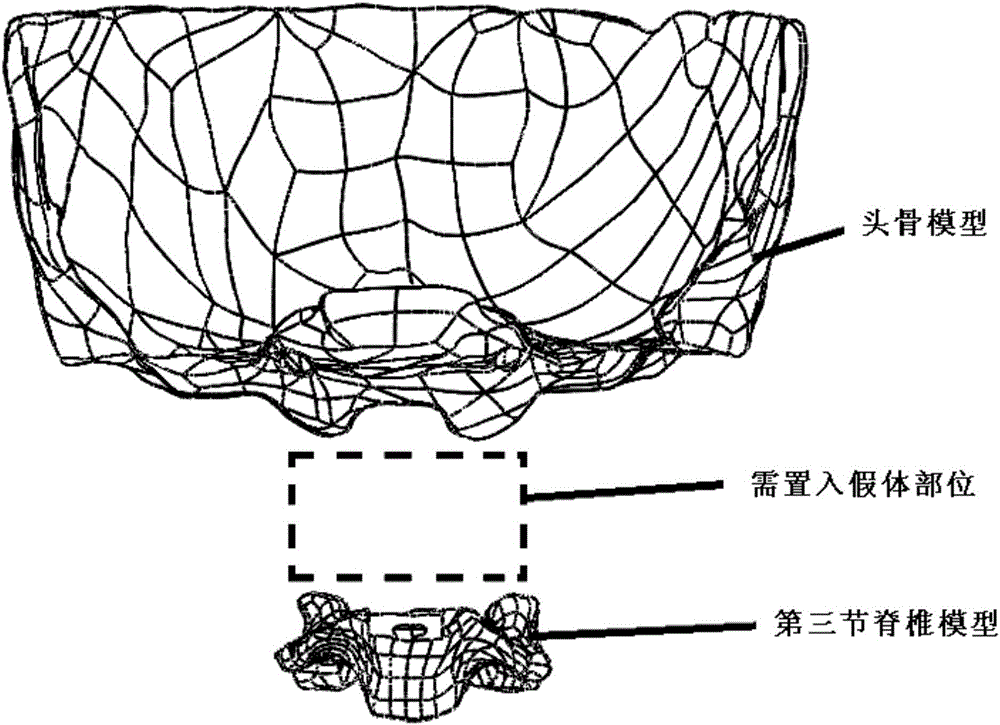

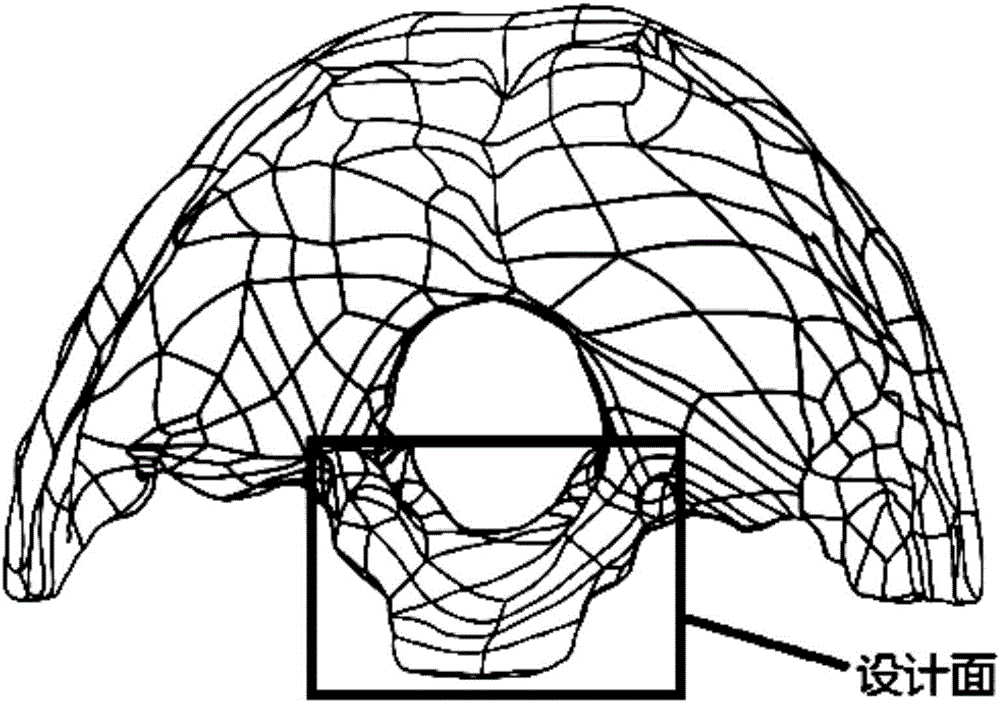

[0036] The manufacturing process of the atlas and axis titanium alloy prosthesis of the present invention is to import the CT tomographic data of the spine medical image DICOM format that the patient needs to reconstruct into the MINICS software, and establish the three-dimensional model data of the spine that needs to be repaired, and the data is stored in the Geomagic software. , perform trimming and noise reduction, export the 3D data file in STEP format, import it into SolidWorks software, select the appropriate design surface at the spine model and skull model of the third section, and establish the prototype of the prosthesis between the two design surfaces to ensure that the prosthesis It fits perfectly with the two design surfaces. In order to reduce the elastic modulus of the prosthesis and realize the lightweight design, the interior of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com