Preparation method of activated carbon filter screen shaping material

A molding material, activated carbon technology, applied in filtration separation, separation method, dispersed particle filtration, etc., to achieve the effect of improved adsorption performance, good mechanical performance, and high bearing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

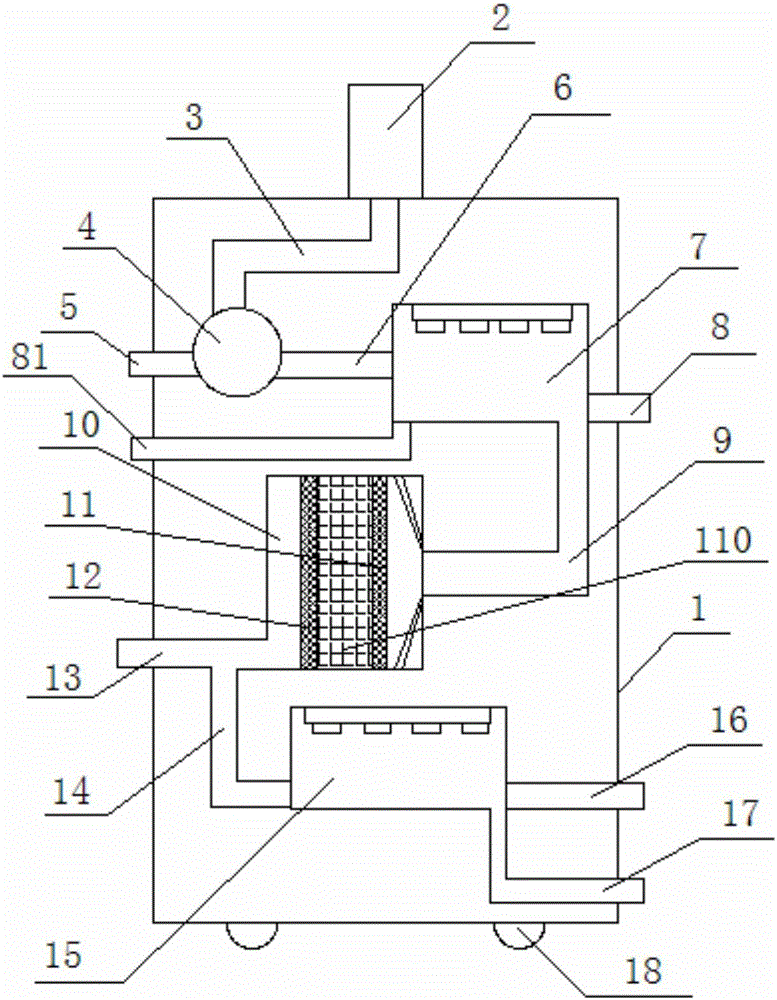

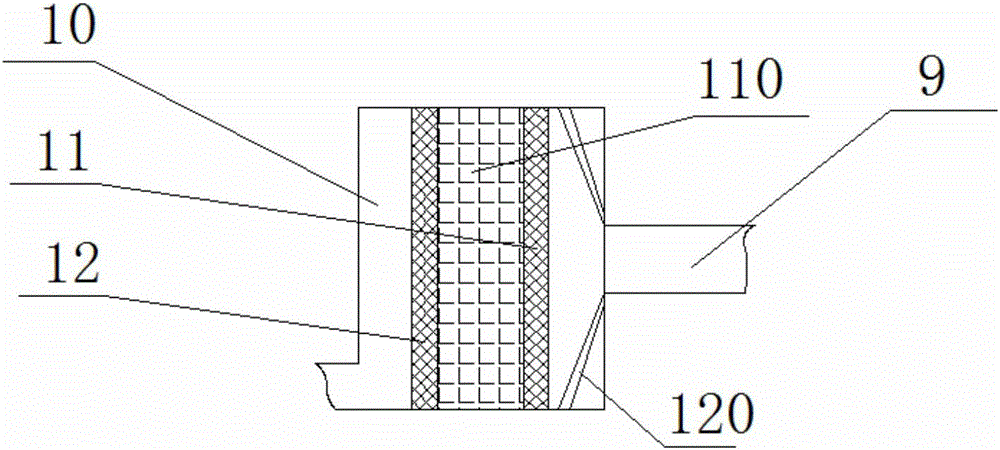

[0033] Such as Figure 1 to Figure 2 As shown, the present invention provides a boiler exhaust gas purification device, comprising: a box body 1, an air inlet pipe 2 arranged at the top of the box body 1, a first pipeline 3 communicated with the air inlet pipe 2, and a desulfurization pump communicated with the first pipeline 3 4. The second pipeline 6 communicated with the desulfurization pump 4, the dilute nitric acid spray chamber 7 communicated with the second pipeline 6, the third pipeline 9 communicated with the dilute nitric acid spray chamber 7, and the adsorber communicated with the third pipeline 9 10. The fourth pipeline 14 communicated with the adsorber 10, the clean water spray chamber 15 communicated with the fourth pipeline 14, the gas outlet pipe 17 communicated with the clean water spray chamber 15, the boiler waste gas can enter from the intake pipe 2, and pass through the desulfurization pump 4. Perform desulfurization treatment, then denitrification treatme...

Embodiment 2

[0037] Activated carbon filter screen forming material is made of the following raw materials in parts by weight:

[0038] 50 parts of activated carbon, 10 parts of glass fiber, 5 parts of aluminum oxide, 5 parts of calcium hypophosphite, 3 parts of paeoniflorin, and 10 parts of glycerin.

[0039] A preparation method for an active carbon filter screen forming material, comprising the steps of:

[0040] ①. Add 25 parts of activated carbon, 5 parts of glass fiber, 5 parts of calcium hypophosphite and 10 parts of glycerin into the reaction vessel, and stir for 20 minutes at a speed of 1000 rpm and a temperature of 50°C;

[0041] ②. Add 25 parts of activated carbon and 5 parts of alumina to the reaction vessel, and stir for 5 minutes at a speed of 1500 rpm and a temperature of 35°C;

[0042] ③. Add 5 parts of glass fiber and 3 parts of paeoniflorol into the reaction vessel, and stir for 30 minutes at a speed of 1250 rpm and a temperature of 70° C. to obtain a mixed powder, which...

Embodiment 3

[0044]The adsorber of the boiler exhaust gas purification device is provided with an activated carbon filter, a HEPA filter and a ceramic filter in sequence along the air intake direction, and the activated carbon filter is made of activated carbon filter forming material.

[0045] The manufacture method of the activated carbon filter screen of the adsorber of the boiler exhaust gas purification device comprises the following steps:

[0046] 1. Activated carbon filter screen forming material (prepared in embodiment 2) is heated to a molten state, and is sieved with a 500 mesh screen;

[0047] ②. Fill the molten material into the processing mold and keep it under 10MPa pressure for 5 minutes;

[0048] ③, naturally cool to room temperature, then demoulding to obtain the filter screen blank;

[0049] ④, put it into a heat treatment furnace for 30 minutes, and the treatment temperature is 200° C. to obtain an activated carbon filter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com