Barium-silicon tungsten oxygen cluster catalyst, preparation method and application thereof

A catalyst, silicon tungsten technology, applied in the field of preparation of alcohol oxidation catalyst materials, can solve the problems of large catalyst consumption and low activity, achieve good catalytic activity, facilitate industrial production, and facilitate easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

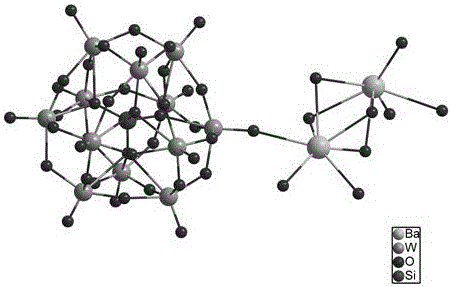

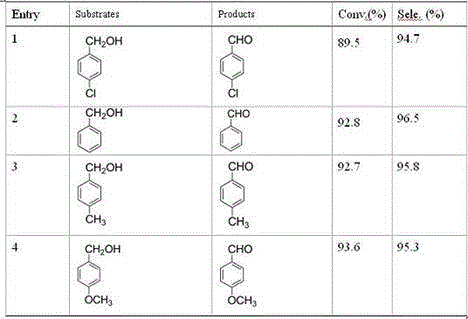

Image

Examples

Embodiment 1

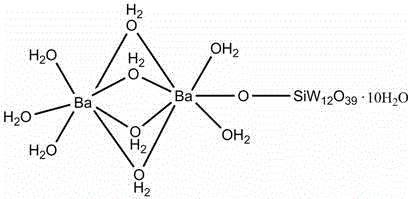

[0030] Embodiment 1: compound [Ba 2 (H 2 O) 9 ] SiW 12 o 40 10H 2 Preparation of O

[0031] Add barium chloride (3mmol), sodium silicate (2mmol), sodium tungstate (30mmol) and water 15mL sequentially into a 25mL polytetrafluoroethylene reaction kettle, stir for 2h, then add dilute hydrochloric acid to adjust the pH to 4, and then React at 120°C for 3 days, cool to room temperature, and filter to obtain colorless crystals [Ba 2 (H 2 O) 9 ] SiW 12 o 40 10H 2 O. The yield is about 44%.

Embodiment 2

[0032] Embodiment 2: compound [Ba 2 (H 2 O) 9 ] SiW 12 o 40 10H 2 Preparation of O

[0033] Add barium chloride (3mmol), sodium silicate (3mmol), sodium tungstate (32mmol) and water 16mL sequentially into a 25mL polytetrafluoroethylene reactor, stir for 2h, then add dilute hydrochloric acid to adjust the pH to 4, Reacted at 130 °C for 3 days, cooled to room temperature, and filtered to obtain colorless crystals [Ba 2 (H 2 O) 9 ] SiW 12 o 40 10H 2 O. The yield is about 48%.

Embodiment 3

[0034] Embodiment 3: compound [Ba 2 (H 2 O) 9 ] SiW 12 o 40 10H 2 Preparation of O

[0035] Add barium chloride (4mmol), sodium silicate (3mmol), sodium tungstate (35mmol) and water 18mL sequentially into a 25mL polytetrafluoroethylene reactor, stir for 5h, then add dilute hydrochloric acid to adjust the pH to 6, React at 160°C for 6 days, cool to room temperature, and filter to obtain colorless crystals [Ba 2 (H 2 O) 9 ] SiW 12 o 40 10H 2 O. The yield is about 62%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com