A kind of spherical aluminum-containing mesoporous composite material and supported catalyst, its preparation method and application, and the method of cyclohexanone glycerol ketal

A composite material and aluminum mesoporous technology, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve equipment corrosion, low conversion rate of reaction raw materials, process Complicated and other issues, to achieve the effect of less side reactions, environmental protection, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a method for preparing a spherical aluminum-containing mesoporous composite material, which comprises the following steps:

[0034] (1) providing a mesoporous molecular sieve material with a hexagonal pore structure or preparing a filter cake of the mesoporous molecular sieve material with a hexagonal pore structure, as component a;

[0035] (2) providing silica gel or a filter cake for preparing silica gel as component b;

[0036] (3) mixing the component a and the component b and performing ball milling in a high-alumina ceramic tank, slurries the solid powder obtained after the ball milling with water, and then spray-dries the obtained slurry;

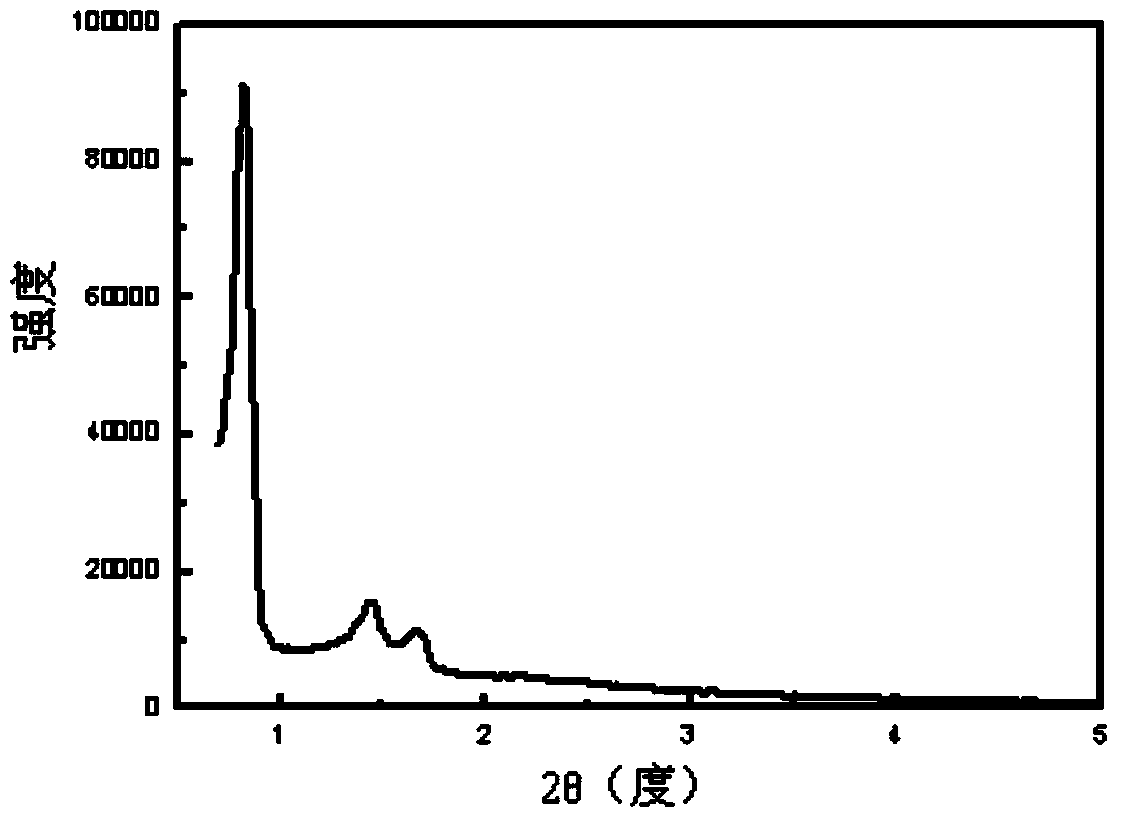

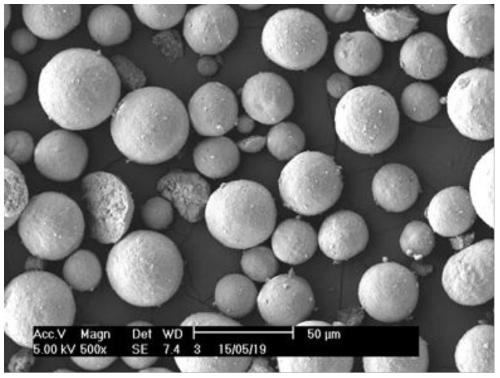

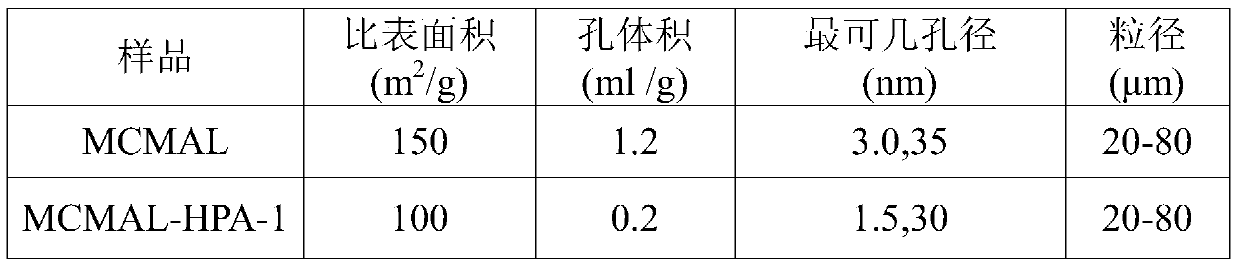

[0037]Wherein, the component a makes the spherical aluminum-containing mesoporous composite material have an average particle size of 20-80 microns, a specific surface area of 100-200 square meters / g, a pore volume of 0.5-1.5 ml / g, and a pore size of A bimodal distribution, and the most ...

Embodiment 1

[0074] This example is used to illustrate the spherical aluminum-containing mesoporous composite material and the supported catalyst of the present invention and their preparation methods.

[0075] (1) Preparation of spherical aluminum-containing mesoporous composites

[0076] Cetyltrimethylammonium bromide and tetraethyl orthosilicate are added in the ammonia solution that the concentration is 25% by weight, wherein, the addition of tetraethyl orthosilicate is 1.0g, and the molar feeding ratio is orthosilicic acid. Ethyl ester: cetyl trimethyl ammonium bromide: ammonia water (25%): deionized water = actual ratio 1: 0.37: 2.8: 142, stirred at 80 ° C until dissolved, the solution was suction filtered and obtained Porous material filter cake, the filter cake is washed to pH 7 to obtain filter cake A1 of mesoporous molecular sieve material with hexagonal structure;

[0077] The water glass with a concentration of 15% by weight and the sulfuric acid solution with a concentration ...

experiment Embodiment 1

[0093] This experimental example is used to illustrate the catalytic activity of the supported phosphotungstic acid catalyst according to the present invention.

[0094] The supported phosphotungstic acid catalyst (MCMAL-HPA-1) in Example 1 was vacuum-dried at 150 ° C for 6 hours, cooled to room temperature, weighed 0.5 g, and then weighed 11.3 g of cyclohexanone and 9.2 g of propylene The triol was placed in a 100ml three-necked flask in turn, stirred at 100°C under reflux for 2 hours, cooled to room temperature, separated by suction filtration, and analyzed by gas chromatography-mass spectrometry to analyze the liquid phase composition of the reaction product and the conversion of cyclohexanone. The yield was 75%, and the yield of cyclohexanone glycerol ketal was 70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com