Pulverizer and application thereof

A pulverizer and grinding chamber technology, applied in the field of grinding, can solve problems such as uneven feeding speed, easy blockage at the outlet, uncontrollable feeding volume, etc., and achieve the effect of clean feeding, convenient feeding, and increased mesh number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

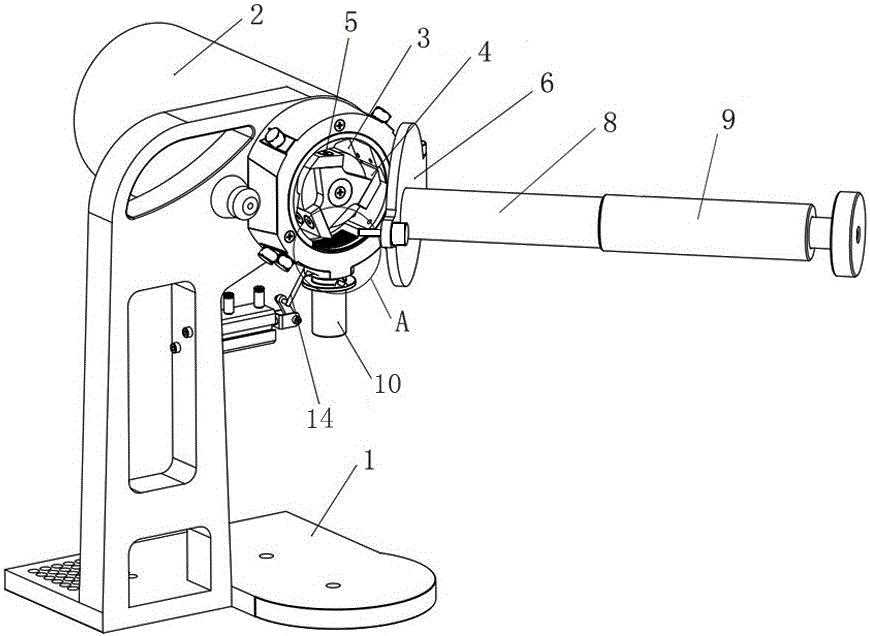

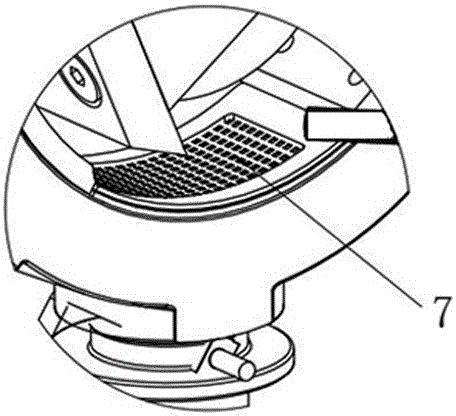

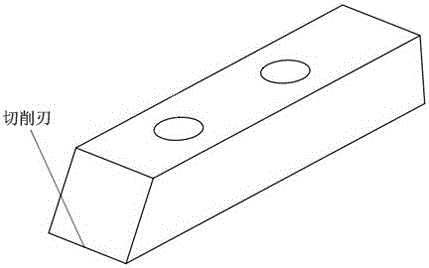

[0022] Embodiment 1: As shown in the accompanying drawings, a pulverizer includes a base 1, a motor 2, a grinding chamber 3 and a discharge port 10, and the grinding chamber 3 is provided with a rotor blade 4, a stator blade 5 and two A filter screen 7 with a layer structure, a cover plate 6 is provided on one side of the grinding chamber 3, and a feed pipe 8 is provided in the middle of the cover plate 6, and the feed pipe 8 is matched with the feeder 9 to complete feeding. The feeder 9 comprises a feeding tube 11, a push rod 12 and a handle 13; a powder sweeping device 14 is also provided under the filter screen 7, and the powder sweeping device 14 includes a cylinder 15, three connecting rods 16 and a hairbrush 17, so The cylinder 15 is fixed to the base 1. The stator blade comprises two-sided cutting edges 18 and connecting holes 19 .

Embodiment 2

[0023] Embodiment 2: the use of a kind of milling machine as described above, for Chinese medicinal materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com