Method for remedying heavy metal contaminated soil through passivation

A technology of polluted soil and heavy metals, which is applied in the restoration of polluted soil and the removal of solid waste, etc., can solve the problems of complicated process, fertilizer efficiency, safety and durability to be observed, heavy metal passivation repair without data support, etc., to achieve broad The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

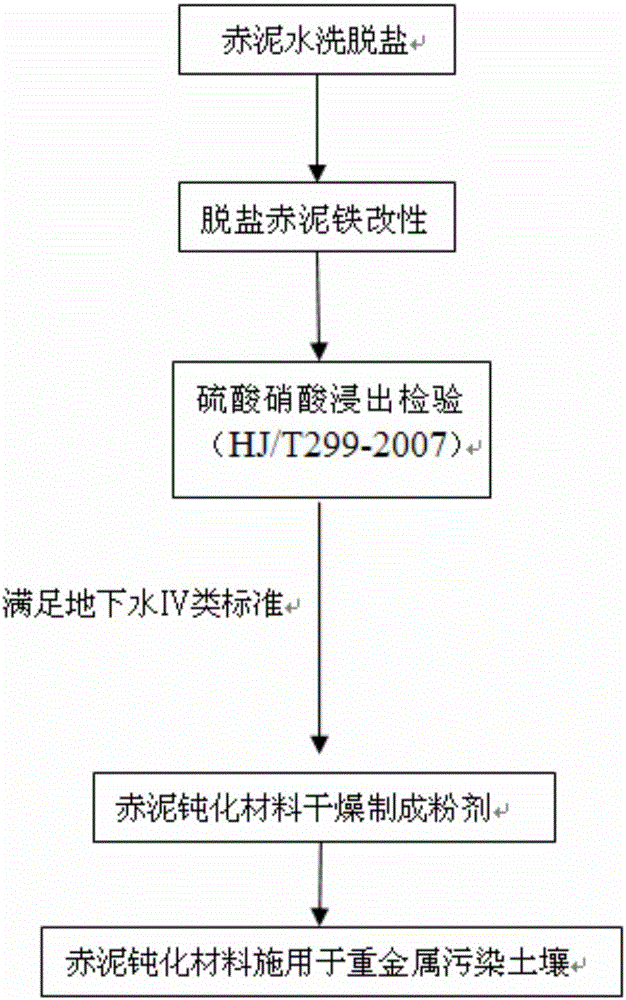

Method used

Image

Examples

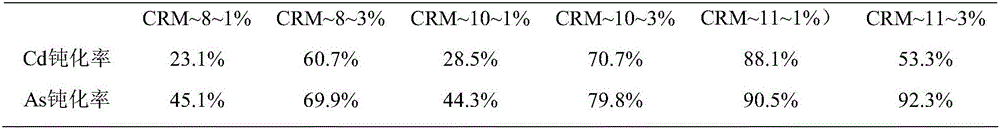

Embodiment 1

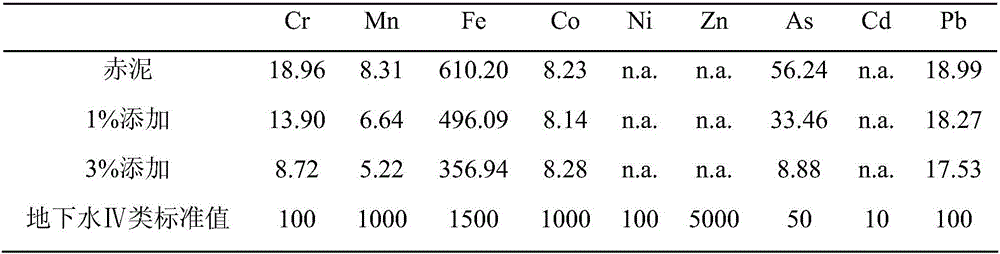

[0053] Passivation treatment experiment: Weigh 100g of heavy metal-contaminated soil through a 2mm sieve, numbered ①, ②, ③, ④, ⑤, ⑥, add 0.5g of iron-modified red mud dry powder in sequence, and correspondingly improve The treatment is as follows: ① Desalted red mud pH = 8, ferrous sulfate addition is 1% (recorded as CRM ~ 8 ~ 1%); ② desalted red mud pH = 8, ferrous sulfate addition is 3% (recorded as CRM ~8~3%); ③Desalted red mud pH=10, ferrous sulfate addition is 1% (denoted as CRM~10~1%); ④Desalted red mud pH=10, ferrous sulfate addition is 3% (Recorded as CRM~10~3%); ⑤Desalted red mud pH=11, ferrous sulfate addition is 1% (recorded as CRM~11~1%); ⑥Desalted red mud pH=11, ferrous sulfate added The amount is 3% (recorded as CRM ~ 11 ~ 3%); then add 60.3mL of deionized water, stir well to form a uniform slurry, and maintain it at a temperature of 25°C ± 0.5°C and a humidity of 95%. After curing for 25-35 days, samples were taken, dried, ground, passed through a 0.125mm sieve...

Embodiment 2

[0057] Passivation treatment experiment: Weigh 100g of heavy metal-contaminated soil passed through a 2mm sieve, numbered as ①, ②, ③, ④, ⑤, ⑥, and add 1g of iron-modified red mud dry powder in turn with different improvement treatments. It is: ①The desalted red mud pH=8, the ferrous sulfate addition is 1% (recorded as CRM~8~1%); ②The desalted red mud is pH=8, the ferrous sulfate addition is 3% (recorded as CRM~ 8~3%); ③Desalted red mud pH=10, ferrous sulfate addition is 1% (recorded as CRM~10~1%); ④Desalted red mud pH=10, ferrous sulfate addition is 3% ( Recorded as CRM ~ 10 ~ 3%); ⑤ desalted red mud pH = 11, the amount of ferrous sulfate added is 1% (recorded as CRM ~ 11 ~ 1%); ⑥ desalted red mud pH = 11, the amount of ferrous sulfate added 3% (recorded as CRM ~ 11 ~ 3%); then add 60.6mL of deionized water, stir well to form a uniform slurry, and maintain under the conditions of temperature 25°C ± 0.5°C and humidity 95%. After curing for 25-35 days, samples were taken, dried...

Embodiment 3

[0061] Passivation treatment experiment: Weigh 100g of heavy metal-contaminated soil that passed through a 2mm sieve, numbered ①, ②, ③, ④, ⑤, ⑥, add 2g of iron-modified red mud dry powder with different improvement treatments in turn, and the corresponding improvement treatment It is: ①The desalted red mud pH=8, the ferrous sulfate addition is 1% (recorded as CRM~8~1%); ②The desalted red mud is pH=8, the ferrous sulfate addition is 3% (recorded as CRM~ 8~3%); ③Desalted red mud pH=10, ferrous sulfate addition is 1% (recorded as CRM~10~1%); ④Desalted red mud pH=10, ferrous sulfate addition is 3% ( Recorded as CRM ~ 10 ~ 3%); ⑤ desalted red mud pH = 11, the amount of ferrous sulfate added is 1% (recorded as CRM ~ 11 ~ 1%); ⑥ desalted red mud pH = 11, the amount of ferrous sulfate added 3% (denoted as CRM ~ 11 ~ 3%); then add 61.2mL of deionized water, stir well to form a uniform slurry, and maintain at a temperature of 25°C ± 0.5°C and a humidity of 95%. After curing for 25-35 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com