Livestock and poultry manure resource utilization method

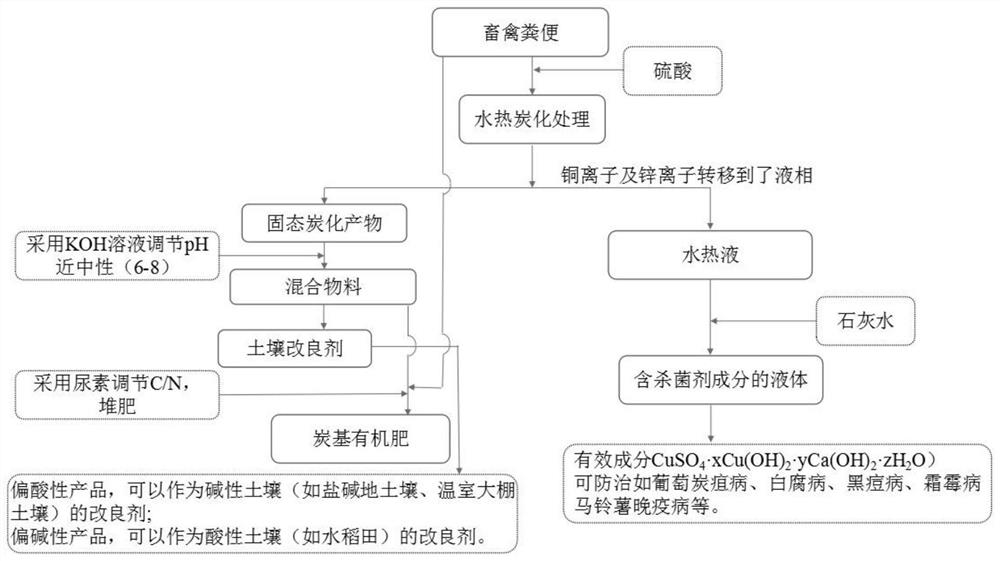

A technology for recycling livestock and poultry manure, which is applied in the field of resource utilization of livestock and poultry manure, can solve the problems of secondary pollution, long period of decomposing process and high transportation cost, and achieves mild reaction conditions, high yield and simple operation steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]The livestock and poultry manure in this embodiment is specifically pig manure from a pig farm, and the solid content is 30-50wt%, Cu2+The content is 800~1500mg / kg; the treatment method of the animal manure is as follows:

[0039]Mix livestock and poultry manure with sulfuric acid with a concentration of 10wt%, wherein the molar ratio of copper ion in livestock manure to sulfate in sulfuric acid is 1:2.0, so that copper ions are fully combined with sulfate to form copper sulfate; The solid content of the system was adjusted to 20wt%, transferred to a hydrothermal reactor, heated to 120°C, and carried out hydrothermal carbonization reaction for 6h; after the hydrothermal carbonization reaction was completed, the resulting system was cooled to room temperature (25°C) and then pumped Filter to obtain solid carbonized product and hydrothermal liquid;

[0040]Mix the potassium hydroxide solution with a concentration of 10wt% with the solid carbonized product so that the pH of the resulti...

Embodiment 2

[0043]In this example, livestock manure is specifically chicken manure from a chicken farm, with a solid content of 40 to 70 wt%, and Cu2+The content is 500~1000mg / kg; the treatment method of the animal manure is as follows:

[0044]Mix livestock and poultry manure with sulfuric acid with a concentration of 1% by weight, wherein the molar ratio of copper ion in livestock manure to sulfate in sulfuric acid is 1:1.0, so that the copper ion is fully combined with sulfate to form copper sulfate; The solid content of the system was adjusted to 30wt%, transferred to a hydrothermal reactor, heated to 280°C, and carried out a hydrothermal carbonization reaction for 0.5h; after the hydrothermal carbonization reaction was completed, the resulting system was cooled to room temperature (25°C) before proceeding Suction filtration to obtain solid carbonized product and hydrothermal liquid;

[0045]Mix potassium hydroxide solution with a concentration of 1% by weight with the solid carbonized product, s...

Embodiment 3

[0048]The livestock and poultry manure in this embodiment is specifically cattle manure from a cattle farm, and the solid content is 20-50wt%, and Cu2+The content is 200~500mg / kg; the treatment method of the animal manure is as follows:

[0049]Mix livestock manure with sulfuric acid with a concentration of 5wt%, wherein the molar ratio of copper ion in livestock manure to sulfate radical in sulfuric acid is 1:1.5, so that copper ion is fully combined with sulfate radical to form copper sulfate; The solid content of the system was adjusted to 15wt%, transferred to a hydrothermal reactor, heated to 120℃, and carried out hydrothermal carbonization reaction for 6h; after the hydrothermal carbonization reaction was completed, the resulting system was cooled to room temperature (25℃) and then pumped Filter to obtain solid carbonized product and hydrothermal liquid;

[0050]Mixing a potassium hydroxide solution with a concentration of 5% by weight with the solid carbonized product, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com