Method for repairing heavy metal polluted soil based on permeation absorption wall

A technology of polluted soil and heavy metals, which is applied in the field of remediation of heavy metal-contaminated soils, can solve the problems of low efficiency of engineering treatment, and achieve the effect of obvious energy-saving advantages, obvious effects, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Soil digestion process

[0047] Using "S" type sampling, select the upper, middle and lower positions of the soil before and after leaching for sampling, and dry the collected samples at 120 °C. After drying, use a grinder and a vibrating sieve to pass the soil through 80 meshes. Accurately weigh 0.100g of soil, add 5mL of concentrated nitric acid and 1mL of hydrofluoric acid, and microwave for 30min at 700W and 150°C. When it is cooled to room temperature, put the digestion tube into a water bath to heat, and carry out acid removal treatment on the digestion liquid. Afterwards, the liquid in Xiaoye’s tube was diluted to 10mL, and 0.1mL was taken to dilute to 10mL. Sampling was repeated 3 times, pending detection and processing.

Embodiment 2

[0049] ICP / AES detection of heavy metals

[0050] Draw 0, 0.1, 0.2, 0.3, 0.4 and 0.5mL of 26 mixed standard solutions of 1μg / mL, dilute to 50mL with 1% nitric acid solution respectively, shake well, stand for 30min for measurement, draw copper, zinc, lead, chromium , cadmium, and arsenic standard curves, the concentrations of copper, zinc, lead, chromium, cadmium, and arsenic in the standard curves are 0, 2.0, 4.0, 6.0, 8.0, and 10 μg / mL, respectively.

[0051] In the same way, with the mercury standard solution, the standard curve of mercury can be drawn, and the standard curve contains mercury 0, 2.0, 4.0, 6.0, 8.0, 10 μg / mL.

[0052] The content of heavy metals can be obtained by direct detection of soil samples, permeate, and washing liquid after decontamination treatment.

Embodiment 3

[0054] (1) Construction of infiltration adsorption wall

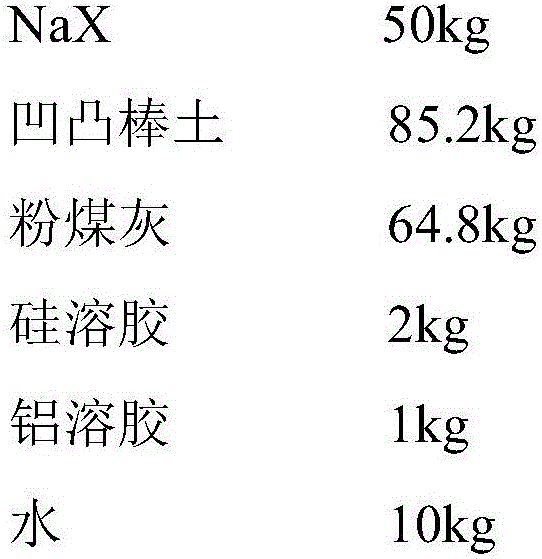

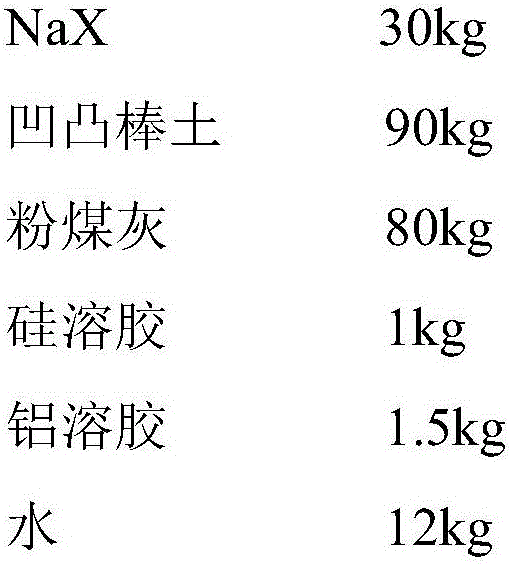

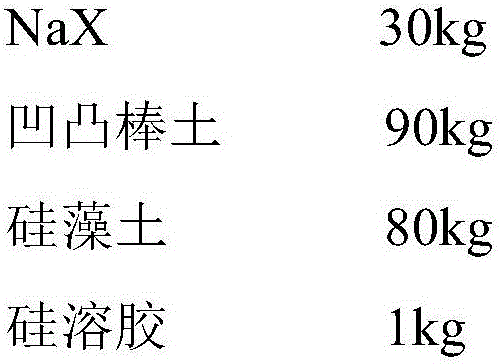

[0055] The total amount of adsorption materials in the osmotic adsorption wall is calculated as 200kg, and the quality of binder and water is not included in it. The ratio of adsorption materials is as follows:

[0056]

[0057] Mix well at room temperature, and prepare the adsorption material into an adsorption brick of 20cm×10cm×3cm by extrusion molding. Keep the humidity at 80%, dry at 120°C for 6h, and at 550°C for 2h. After cooling to room temperature, the adsorption bricks are fixed and stacked with stainless steel frames to form permeable adsorption walls of different sizes and specifications, and spliced by permeable adsorption bricks to form a 0.8m 3 The left and right cuboids are not capped. The bottom layer is paved with foam plastic, and the four sides of the cuboid are spliced by two permeable adsorption walls, and the distance between the two adsorption walls is 10cm.

[0058] (2) Soil washing

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com