Operation method of extrusion molding system after paper-plastic separation

A paper-plastic separation and operation method technology, applied in the separation method, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of high production cost, secondary pollution, complexity, etc., and achieve high production efficiency and low labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

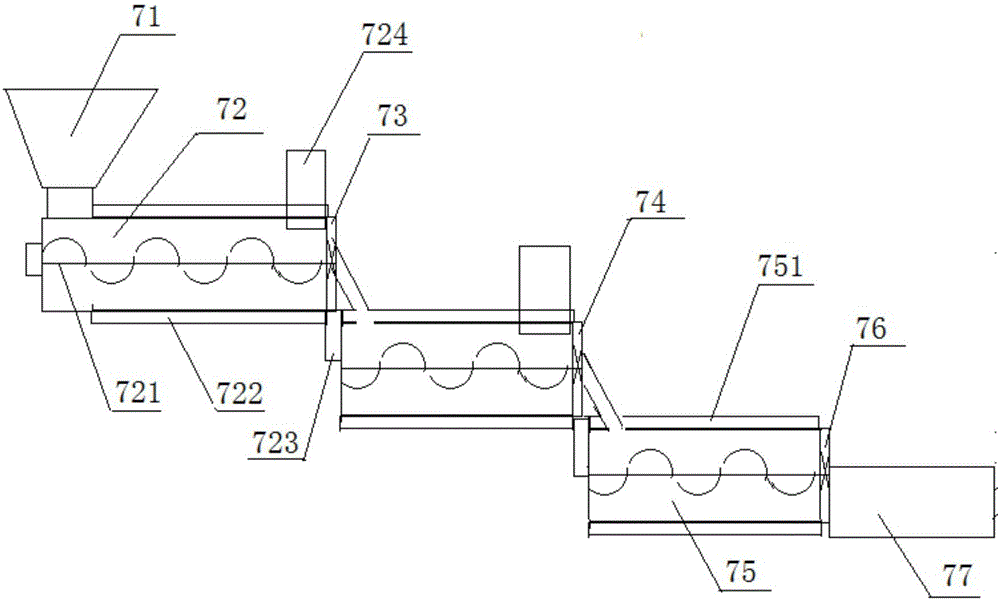

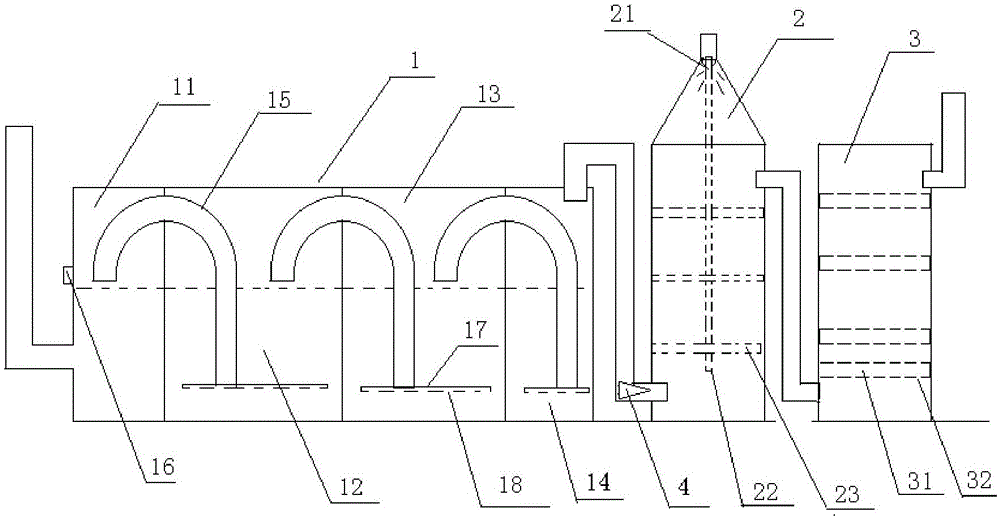

[0040] The operation method of the extrusion molding system after a kind of paper-plastic separation of the present embodiment, such as figure 1 and figure 2 As shown, comprise extruding molding device and smog processing device; Extruding molding device comprises feed hopper 71, extruding mechanism 72, filter mechanism and cooling pool 77; Smog processing device comprises chemical solution treatment box 1, spray tower 2 and Adsorption box 3; wherein: extrusion mechanism 72 includes propeller 721, heater 722, impurity collection box 723 and smoke exhaust pipe 724; propeller 721 is a horizontal barrel-shaped structure, and its left end communicates with the bottom end of feed hopper 71 , the right end communicates with the filter mechanism; the heater 722 covers the outer surface of the propeller 721; the impurity collection box 723 is arranged on the bottom surface of the right end of the propeller 721 near the filter mechanism; the exhaust pipe 724 is arranged on the top sur...

Embodiment 2

[0045] The operating method of the extrusion molding system after the separation of paper and plastic in this embodiment, the basic structure is the same as that of Embodiment 1, the difference is that: the extrusion molding device also includes a cooling molding mechanism 75, the cooling molding mechanism 75 and the second extruder The molding mechanism 72 communicates through the connecting pipe; the right end of the cooling forming mechanism 75 is connected with a filtering mechanism C76, and the cooling pool 77 is arranged at the outlet of the filtering mechanism C76; two extruding mechanisms 72 are arranged, and are communicated by connecting pipes; the filtering mechanism also has 2, for filter mechanism A73 and filter mechanism B74, which communicate with the first and second extrusion mechanism 72 respectively; the propeller 721 is a screw propeller; the heater 722 is a steam heater; the exhaust pipe 724 and the flue gas The purification devices are connected; the filte...

Embodiment 3

[0049]The operation method of the extrusion molding system after the separation of paper and plastic in this embodiment has the same basic structure as that of Embodiment 2, the difference is that an automatic tamping rod is set on the feed hopper 71 to avoid the plastic skin in the feed hopper 71 Lighter without blanking; the heater 722 is an electromagnetic heater; the extruding mechanism is provided with a temperature detection and monitoring mechanism connected with PLC. The inner wall of the first compartment 11 is provided with a cooling water circulation device to ensure that the smoke entering the compartment is quickly reduced to below 30°C. The liquid level of the chemical solution in the chemical solution treatment tank 1 is 70% of the height of the tank; the concentration of the sodium hydroxide solution in the spray tower 2 is 7%. The second compartment 12 hygienic ball add-ons are 70 grams / kg, and the 3rd compartment 13 grapevine acid solution add-ons are 70 gram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com