Conveying system

A conveying system and diverting device technology, which is applied in the direction of conveyors, conveying bulk materials, transportation and packaging, etc., can solve problems such as difficult to replace cleanly, affect fluid conveyance, and high pressure loss, and achieve convenient maintenance and replacement in the later stage, and steam density Uniform and stable delivery pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

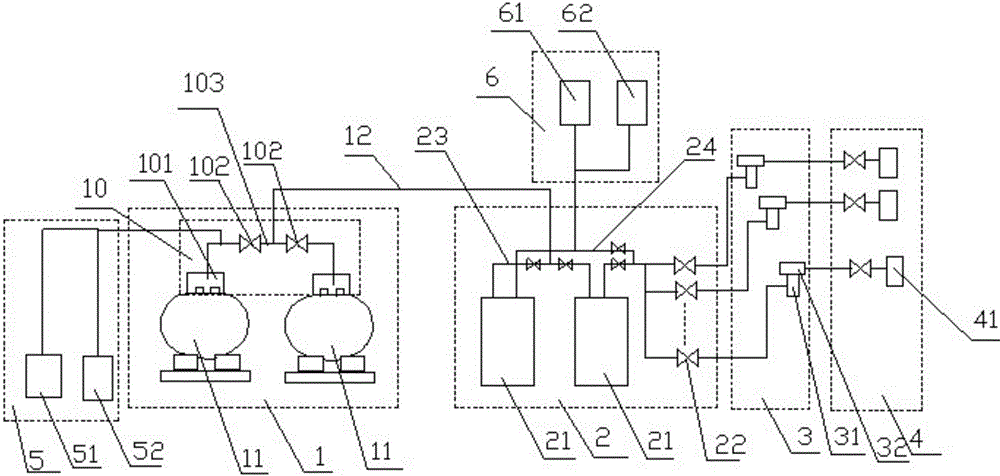

[0024] Such as figure 1 As shown, a conveying system is disclosed in this embodiment, which sequentially includes a raw material supply device 1, a flow diversion device 2, a vaporization device 3 and a deposition device 4, the above-mentioned raw material supply device 1, flow diversion device 2, vaporization device 3 and deposition device 4 They are connected by pipelines to form fluid raw material delivery pipelines, and the ends of the above-mentioned deposition devices 4 are connected to various material consumption points.

[0025] The above-mentioned vaporization device 3 is the core part of the system, and is the core equipment for whether the whole system can produce qualified preforms, and can directly affect the optical properties of the preforms after subsequent deposition. Specifically, the vaporization device 3 includes several raw material heating tanks 31 , a delivery valve group panel 32 and a mass flow meter arranged on the feeding ports of the raw material h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com