Method for synthesizing carbon quantum dots from water chestnuts and application of carbon quantum dots

A technology of carbon quantum dots and water chestnuts, which is applied in the field of microwave synthesis of carbon quantum dots, can solve the problems of time-consuming, unfavorable application, and low quantum yield of carbon dots, and achieve the effects of simple operation, good solubility and dispersibility, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Crush the water chestnuts with a blender, and uniformly mix the crushed water chestnuts and ultrapure water at a mass ratio of 1:10 to prepare a precursor solution for later use.

[0023] (2) The obtained precursor solution was irradiated and heated at a microwave power of 600w for 3min.

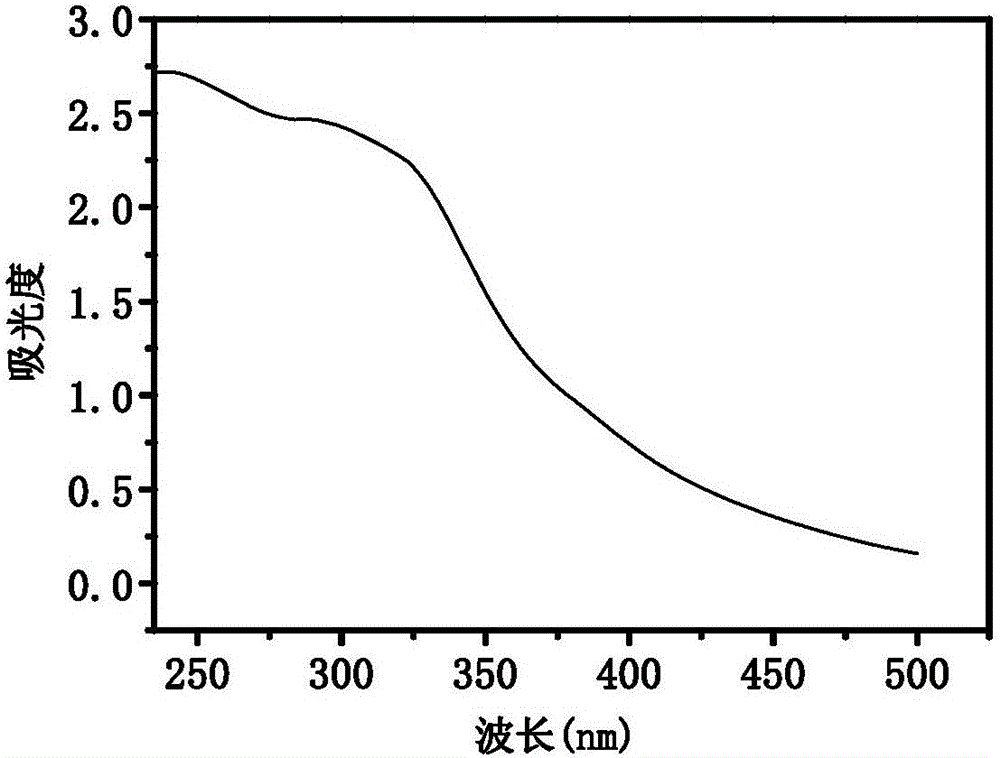

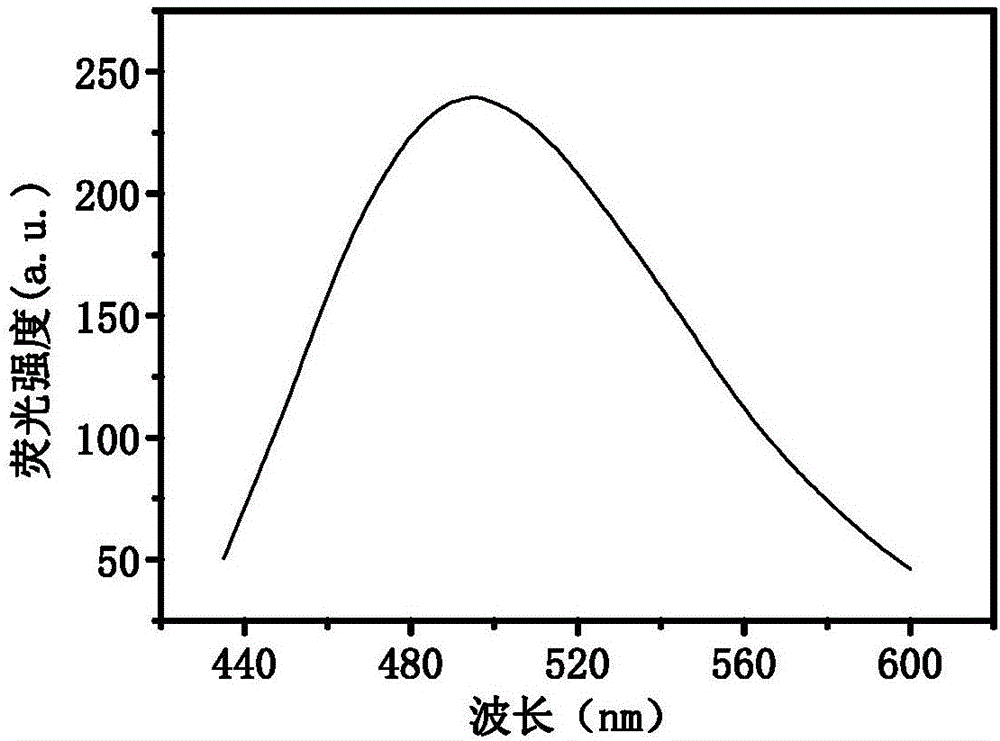

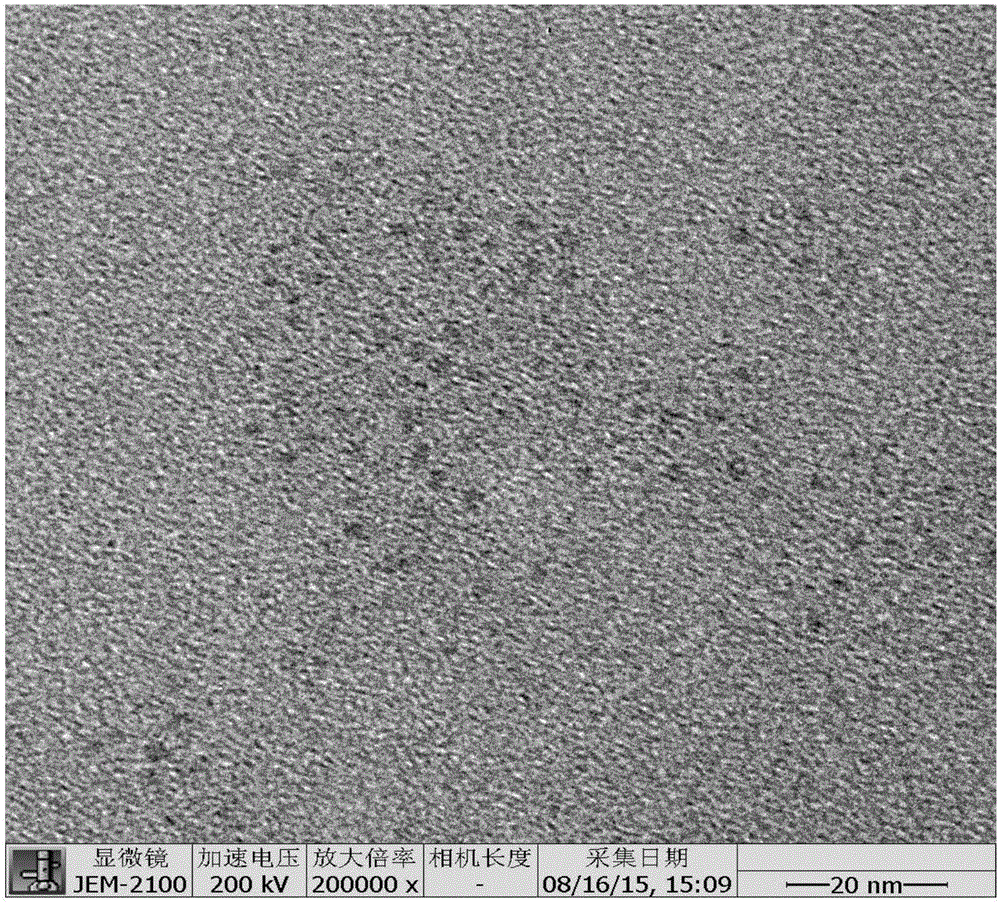

[0024] (3) Take out and cool to room temperature naturally, add deionized water 2.0-3.0 times the volume of the precursor solution, centrifuge to remove insoluble matter, and the supernatant is dialyzed through a 1000Da dialysis bag, and freeze-dried at -50°C to obtain carbon quantum dot powder. The quantum yield was 19.3%.

Embodiment 2

[0026] (1) Crush the water chestnuts with a blender, and uniformly mix the crushed water chestnuts and ultrapure water at a mass ratio of 1:10 to prepare a precursor solution for later use.

[0027] (2) The obtained precursor solution was irradiated and heated at a microwave power of 700w for 3min.

[0028] (3) Take out and cool to room temperature naturally, add deionized water with 2.0-3.0 times the volume of the precursor solution, centrifuge to remove insoluble matter, the supernatant is dialyzed through a 1000Da dialysis bag, and freeze-dried at -50°C to obtain carbon quantum dot powder , with a quantum yield of 21.2%.

Embodiment 3

[0030] (1) Crush the water chestnuts with a blender, and uniformly mix the crushed water chestnuts and ultrapure water at a mass ratio of 1:10 to prepare a precursor solution for later use.

[0031] (2) The obtained precursor solution was radiated and heated for 5 min under a microwave power of 800 W.

[0032] (3) Take out and cool to room temperature naturally, add deionized water with 2.0-3.0 times the volume of the precursor solution, centrifuge to remove insoluble matter, the supernatant is dialyzed through a 1000Da dialysis bag, and freeze-dried at -50°C to obtain carbon quantum dot powder , with a quantum yield of 29.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com