Preparation method of modified attapulgite particles and method for accelerating granulation of anaerobic sludge by modified attapulgite particles

A technology of modifying attapulgite and attapulgite, which is applied in the field of water treatment, can solve problems such as easy dispersion of attapulgite, influence on sludge granulation effect, poor stability, etc., shorten sludge granulation time and improve operation Efficiency and stability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

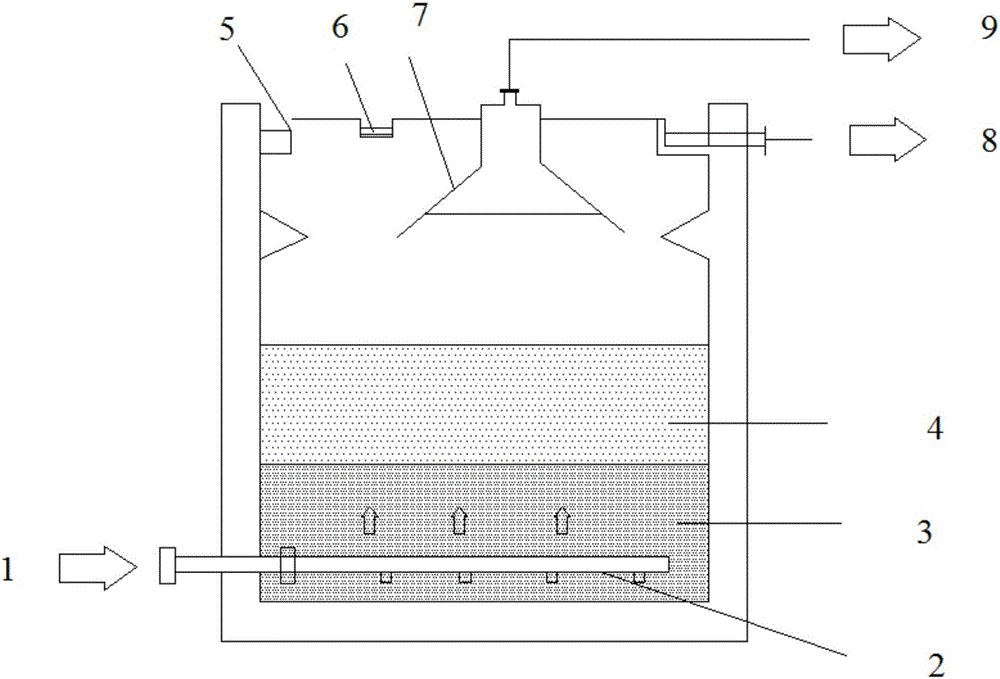

Image

Examples

Embodiment 1

[0033] A method of using modified attapulgite particles to accelerate anaerobic sludge granulation in this embodiment, the steps are:

[0034] Step 1. Preparation of modified attapulgite particles: firstly carry out acid activation treatment on attapulgite, then carry out modification treatment to obtain modified attapulgite, and granulate modified attapulgite to obtain the modified attapulgite of the present invention. Attapulgite particles, the specific steps are as follows:

[0035](1) Acid activation: Add a hydrochloric acid solution with a molar concentration of 1 mol / L to the original soil of attapulgite, shake at room temperature for 30 minutes, filter after standing for precipitation, wash with deionized water until the pH value is 7, and dry at 105 ℃ drying in an oven, grinding and sieving to obtain acid-activated attapulgite, wherein the mass ratio of attapulgite raw soil to hydrochloric acid solution is 1:20. The number of pores and the specific surface area of t...

Embodiment 2

[0045] The method of using modified attapulgite particles to accelerate anaerobic sludge granulation in this embodiment is basically the same as that in Example 1, the main difference is that the modified attapulgite particles account for 5% of the effective volume of the reactor, and the pH value of the influent 7.2. The water temperature is kept at 38°C, and the rising velocity of the water flow in the reactor is 0.8m / h.

Embodiment 3

[0049] The method of using modified attapulgite particles to accelerate anaerobic sludge granulation in this example is basically the same as in Example 1, the main difference is that the number of polyquaternium-7 taken is 3, and the modified attapulgite Soil particles account for 3% of the effective volume of the reactor, the pH value of the influent water is 7.5, the water temperature is 36°C, and the rising velocity of the water flow in the reactor is 0.7m / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com