UASB reactor system based on compression heat pump and method thereof

A reactor system and compression heat pump technology, applied in chemical instruments and methods, fluid heaters, lighting and heating equipment, etc., can solve problems such as low sewage treatment efficiency and reactor pollution to the environment, so as to improve utilization efficiency, improve Biogas production, increase the effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

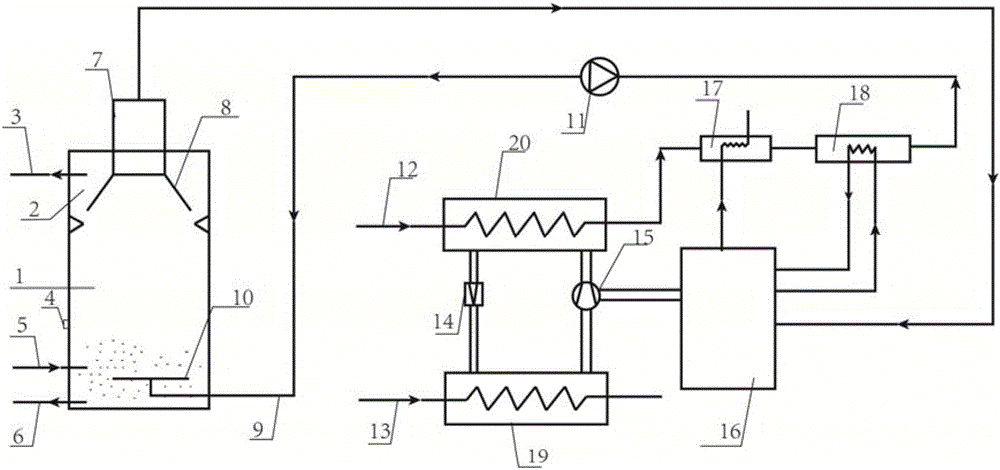

[0011] like figure 1 Shown, the present invention is based on the UASB reactor system of compression heat pump, comprises UASB reactor and heating system, and UASB reactor comprises sludge reaction area 1 and sedimentation area 2, and the bottom of described sludge reaction area 1 contains a large amount of Oxygen sludge forms a sludge layer, and the sewage inlet pipe should extend into the sludge layer; the UASB reactor on one side of the anaerobic sludge is equipped with a heating water inlet pipe 9, and the UASB reactor on the other side is respectively installed The sewage inlet pipe 5, the sludge discharge pipe 6 and the temperature sensor 4, the temperature sensor 4 can monitor the temperature of the sludge reaction zone in real time, so as to adjust the flow of heating hot water; it is installed on the UASB reactor on the top side of the sludge reaction zone 1 Sewage outlet pipe 3; a three-phase separator 8 and a gas collection chamber 7 are also provided on the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com