Waterproof paint for architectural ornament engineering

A technology of architectural decoration engineering and waterproof coating, applied in the field of architectural decoration engineering, can solve problems such as human health and unfavorable environment, and achieve the effect of reducing the pressure of resource shortage, good affinity and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

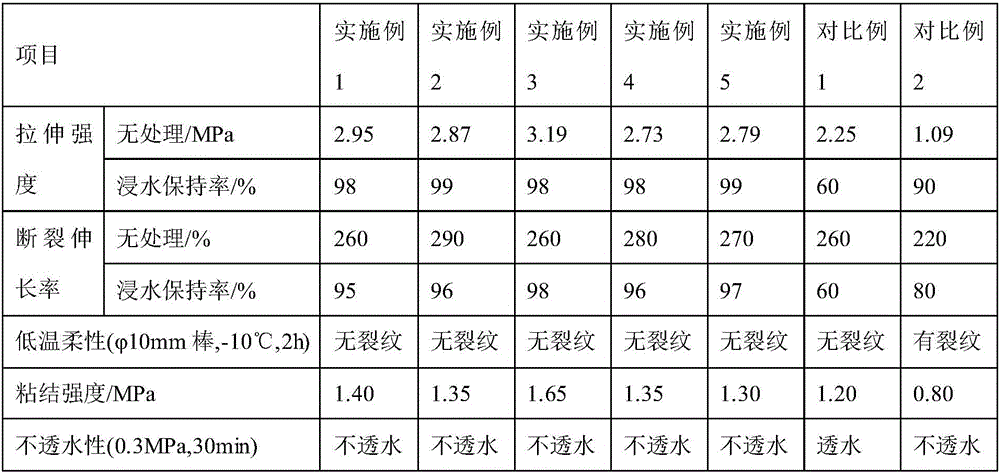

Examples

Embodiment 1

[0039] A waterproof coating for building decoration engineering is composed of solid components and liquid components in a mass ratio of 5:7.

[0040] The solid component includes the following substances in mass percentage: 10% of lithium slag powder, 5% of ceramic tile polishing powder, 1% of magnesium oxide expansion agent, 0.05% of N-perfluoroneoyl acid salt, and 0.1% of sodium aluminosilicate , 0.01% of strengthening agent, 0.1% of thickening and water-retaining agent, 0.1% of dispersing agent, 0.01% of defoaming agent, and the balance is cement.

[0041] The cement is P.O42.5 cement; the fineness of the lithium slag powder is 400 mesh; the fineness of the ceramic tile polishing powder is 400 mesh.

[0042] The enhancer is composed of triethanolamine, ethylenediamine tetramethylene phosphonic acid and calcium sucrose in a mass ratio of 1:2:1.

[0043] The viscosity-increasing and water-retaining agent is composed of sodium polyacrylate, Wenlun gum and guar gum hydroxypro...

Embodiment 2

[0049] A waterproof coating for building decoration engineering is composed of solid components and liquid components in a mass ratio of 9:7.

[0050] The solid component includes the following substances in mass percentage: lithium slag powder 30%, ceramic tile polishing powder 10%, magnesium oxide expansion agent 2%, N-perfluoroneoyl acid salt 1%, sodium aluminosilicate 1% , Strengthening agent .1%, Viscosifying and water-retaining agent 0.5%, Dispersing agent 0.5%, Defoaming agent 0.05%, The balance is cement.

[0051] The cement is P.O42.5 cement; the fineness of the lithium slag powder is 600 mesh; the fineness of the ceramic tile polishing powder is 600 mesh.

[0052] The enhancer is composed of triethanolamine, ethylenediamine tetramethylene phosphonic acid and calcium sucrose in a mass ratio of 2:1:1.

[0053] The viscosity-increasing water-retaining agent is composed of sodium polyacrylate, Wenlun gum and guar gum hydroxypropyltrimethylammonium chloride in a mass rat...

Embodiment 3

[0058] A waterproof coating for building decoration engineering is composed of solid components and liquid components in a mass ratio of 7:7.

[0059] The solid component includes the following substances in mass percentage: lithium slag powder 20%, ceramic tile polishing powder 8%, magnesium oxide expansion agent 1.4%, N-perfluoroneoyl acid salt 0.5%, sodium aluminosilicate 0.5% , 0.05% of strengthening agent, 0.2% of thickening and water-retaining agent, 0.3% of dispersing agent, 0.03% of defoaming agent, and the balance is cement.

[0060]The cement is P.O42.5 cement; the fineness of the lithium slag powder is 500 mesh; the fineness of the ceramic tile polishing powder is 500 mesh.

[0061] The enhancer is composed of triethanolamine, ethylenediamine tetramethylene phosphonic acid and calcium sucrose in a mass ratio of 2:2:1.

[0062] The viscosity-increasing water-retaining agent is composed of sodium polyacrylate, Wenlun gum and guar gum hydroxypropyltrimethylammonium ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com