Concrete retarder, as well as preparation method and application thereof

A technology of concrete and setting retarder, applied in the field of setting retarder, can solve the problems of poor effect of exposed aggregate concrete, easy penetration of the setting retarder into the periphery or the interior of concrete, etc., and achieve the effect of accurate graphics and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

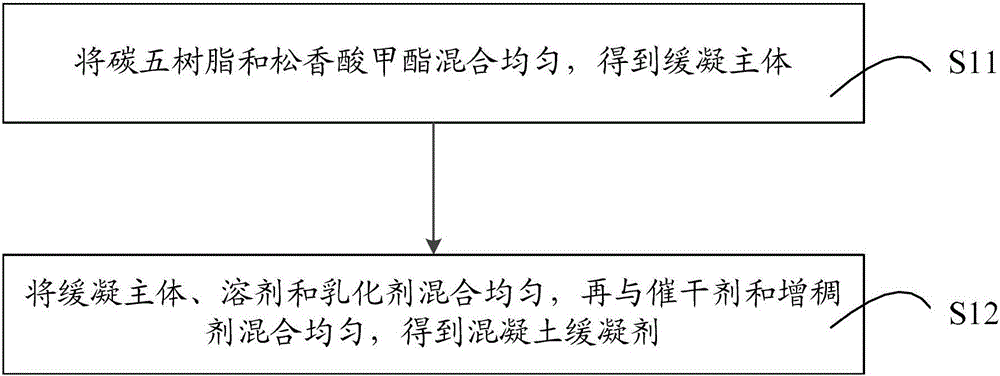

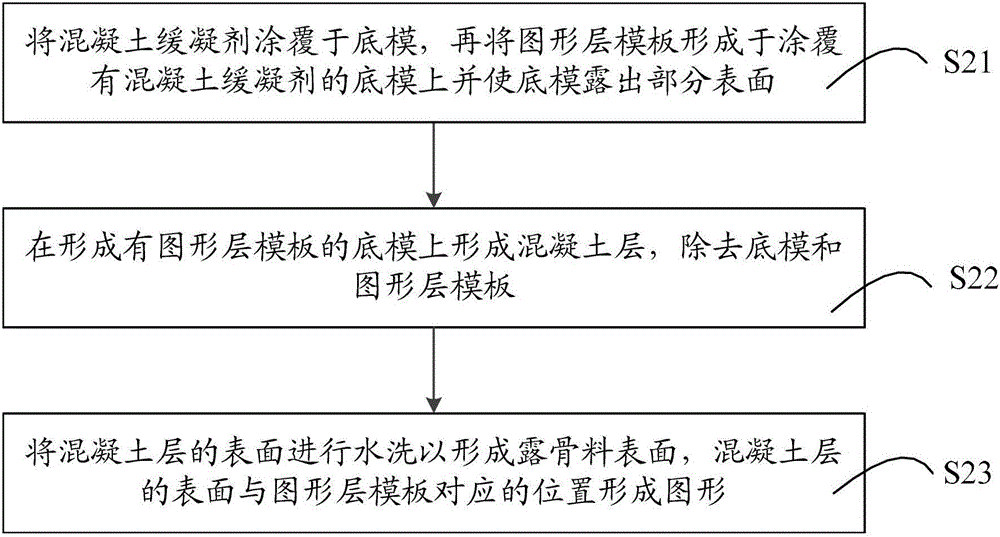

[0038] see figure 1 , the present invention also provides a preparation method of the above-mentioned concrete retarder, the preparation method comprising the following steps.

[0039] Step S11: Mix C5 resin and methyl rosinate evenly to obtain a retarded body.

[0040] Step S12: Mix the retarder body, solvent and emulsifier evenly, and then mix with the drier and thickener to obtain the concrete retarder.

[0041] In one of the embodiments, when the concrete retarder also includes a cosolvent and / or a leveling agent and / or a filler and / or a pigment, after the retarder body, a solvent and an emulsifier are mixed uniformly, the cosolvent and / or Add leveling agent and / or filler and / or pigment and mix evenly.

[0042] Preferably, mechanical agitation is used for mixing both in step S11 and step S12, and the agitation speed is 800-1000 r / min. Preferably, the time for mixing the retarding main body, the solvent and the emulsifier in step S12 is 10 minutes. Preferably, it is eve...

Embodiment 1

[0061] The concrete retarder includes the following components in parts by weight: 27.5 parts of retarding main body, 50 parts of main solvent, 3 parts of emulsifier, 0.3 part of drier, 8 parts of thickener, 0.7 part of auxiliary solvent, 0.5 part Leveling agent, 8 parts of filler and 2 parts of pigment. The mass ratio of carbon five resin and rosin methyl ester in the retarding main body is 10:1, and main solvent is xylene, and emulsifier is OP-109 (alkylphenol polyoxyethylene ether) that Xingtai Lanxing Auxiliary Factory provides, catalyst The drying agent is cobalt drier, the thickener is fumed silica, the cosolvent is cyclohexanone, the leveling agent is hydroxymethyl cellulose ether (molecular weight is about 40,000), and the filler is a mass ratio of 1:1 325 mesh quartz sand and 800 mesh talcum powder, the pigment is iron red.

[0062] The preparation method of the concrete retarder comprises the following steps: uniformly mixing carbon five resin and methyl abietate to...

Embodiment 2

[0064] The concrete retarder includes the following components in parts by weight: 30.5 parts of retarding body, 60 parts of main solvent, 1 part of emulsifier, 0.1 part of drier, 5 parts of thickener, 2 parts of auxiliary solvent, 0.4 part leveling agent and 1 part pigment. The mass ratio of carbon five resin and rosin methyl ester in the retarding main body is 20:1, the main solvent is ethylene glycol ether, the emulsifier is AEO-9 (fatty alcohol polyoxyethylene ether) provided by BASF, and the drier is cobalt The drier and thickener are fumed silica, the cosolvent is cyclohexanone, the leveling agent is M30 cellulose ether (molecular weight is about 40,000) provided by Yilaitai, and the pigment is organic blue. The preparation method of Example 2 is similar to that of Example 1, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com