Production equipment for environment-friendly organic fertilizer and method for producing organic fertilizer

A technology of organic fertilizers and production equipment, which is applied in the preparation of organic fertilizers, organic fertilizers, inorganic fertilizers, etc., can solve the problems of affecting the absorption of nutrients in organic fertilizers, unsatisfactory crushing effects, and low production efficiency, so as to treat and prevent pests and diseases, Ideal crushing effect and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

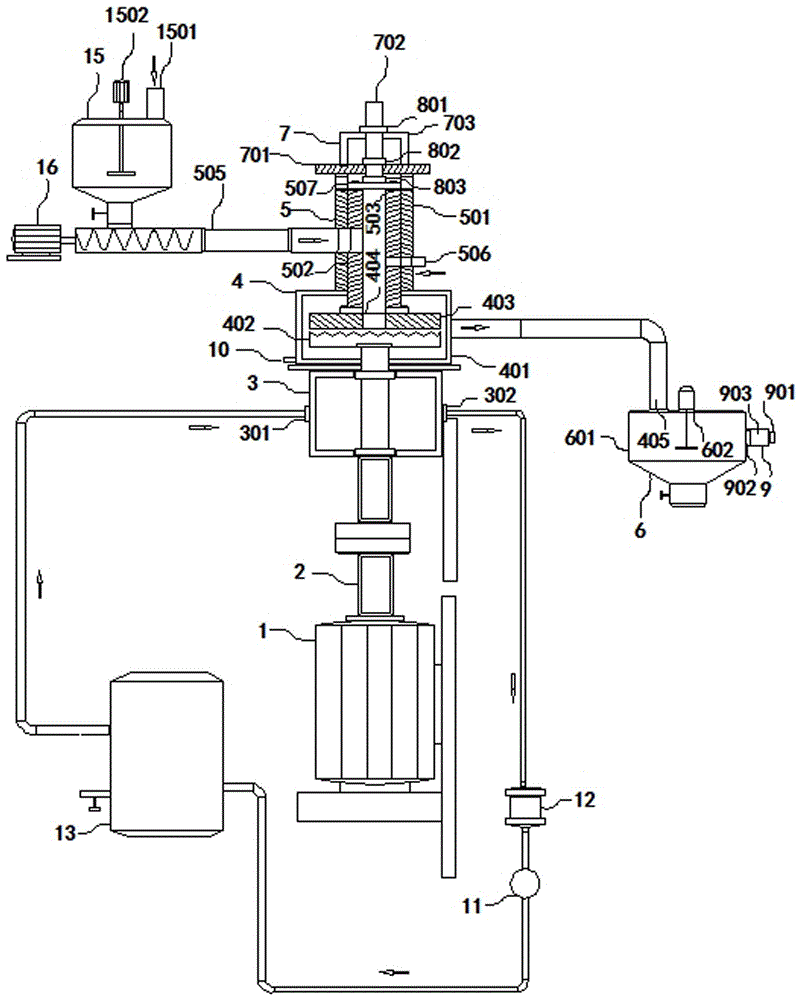

[0042] As shown in the figure, the environment-friendly organic fertilizer production equipment includes a raw material pretreatment unit, a drive motor 1, a drive shaft 2, a heat exchange unit 3, a raw material microprocessing unit 4, a raw material input unit 5 and a material receiving and stirring unit 6; The raw material microprocessing unit 4 is placed on the upper side of the heat exchange unit 3 .

[0043] The raw material microprocessing unit 4 comprises a housing 401, a moving grinding disc 402 and a static grinding disc 403; the moving grinding disc 402 and the static grinding disc 403 are located in the housing 401 and arranged horizontally at a certain distance; the center of the static grinding disc 403 A through hole 404 is provided at the position; a material outlet 405 is provided on the housing 401; the material outlet 405 communicates with the material inlet of the receiving and stirring unit 6; a vacuum suction is provided on the receiving and stirring unit 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com