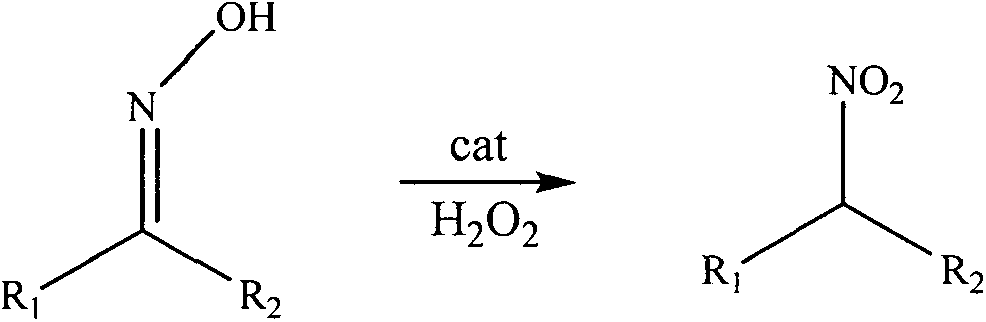

Green synthesis method for preparing nitroalkanes by oxime oxidation

A green synthesis technology of nitroalkanes, applied in the preparation of nitro compounds, organic chemistry, etc., can solve the problems of short life, low catalyst activity, low yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1, embodiment 2 and embodiment 3 are catalyst reuse experiments.

[0018] Example 1:

[0019] After mixing 73g of acetone oxime and 160g of methanol through a mixer, use metering pump A, 97g of hydrogen peroxide (content is 70%), and use metering pump B to continuously add 3g of V-ZSM-5 catalyst (the ratio of silicon to metal is 30), sodium carbonate In a 0.003g reactor, the temperature is 60°C and the pressure is 0.01MPa. The reaction clear liquid separated by the membrane is rectified to obtain 2-nitropropane 85.9g after precipitating, and the yield is 96.5%, and the purity is 99.2%. The unreacted oxime and solvent are recovered and returned to continue the oxidation reaction. V- ZSM-5 catalyst yielded 2.87 g after filtration.

Embodiment 2

[0021] Repeat the experiment with the V-ZSM-5 catalyst recovered above according to the above experiment ratio, and reuse it 8 times, and the yield is all above 95%. In the 9th experiment, the conversion rate dropped to 92%. In the 10th experiment, the conversion rate dropped to 87%.

Embodiment 3

[0023] Butanone oxime 87g and tert-butanol 74g are mixed with metering pump A after mixer, hydrogen peroxide (content is 27.5%) 125g use metering pump B, add continuously to have Zr-V-ZSM-5 catalyzer (silicon metal ratio 50) 14g, potassium bicarbonate 0.3g in the reactor, temperature 65 ℃, pressure 0.05MPa, the reaction clear liquid separated by the membrane was rectified to obtain 2-nitrobutane 99.9g after precipitation, yield 97% , the purity is 99%, and the unreacted oxime and solvent are recovered and returned to continue the oxidation reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com