Resin for antifouling paint and preparation method thereof

A technology of antifouling coatings and resins, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of cumbersome preparation methods, poor antifouling performance, and harsh process conditions, and achieve the goal of preparation Simple process, good anti-fouling performance, good matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

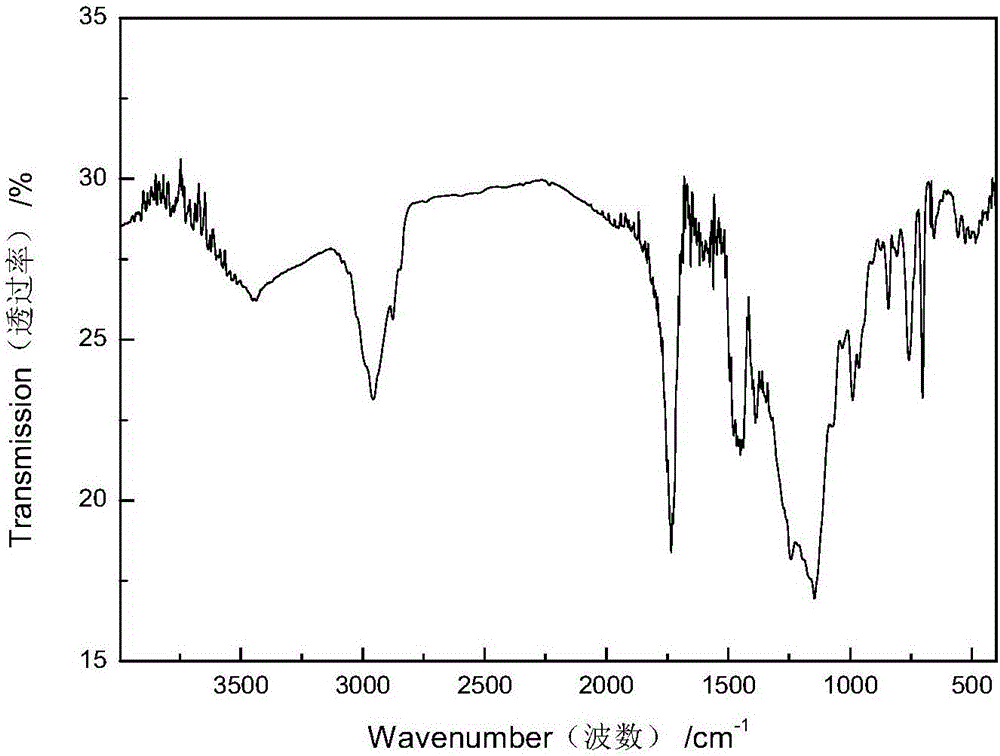

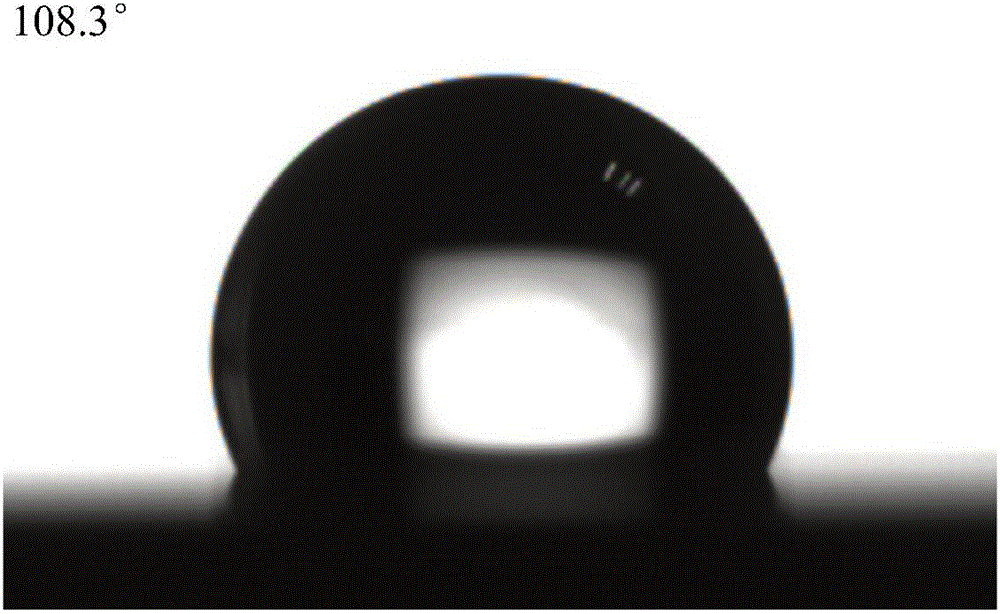

[0033] Mix xylene, n-butyl acetate, and n-butanol uniformly at a mass ratio of 60:25:15 to obtain a mixed solvent; add 2.0 parts of A-171 silane coupling agent and 8.1 parts of the above solvent into the reaction kettle, and heat to 75°C , and stirred; after mixing 23.5 parts of MMA, 17.0 parts of BA, 4.1 parts of st, 2.0 parts of AA, 0.51 parts of BPO initiator, and 20.3 parts of solvent, at 75 ° C, drop it into the above mixture within 2 hours, Continue to stir and keep warm for 2 hours; after mixing 2.0 parts of perfluoroalkyl ethyl methacrylate, 0.02 parts of BPO initiator, and 11.7 parts of solvent, drop them into the above mixture within 1 hour at 75°C and continue stirring , heat preservation for 1 hour; after mixing 0.02 parts of BPO initiator and 8.1 parts of solvent, drop them into the above mixture within 0.5 hours at 75°C, continue stirring and heat preservation for 1.5 hours, then stop stirring, and cool and discharge.

Embodiment 2

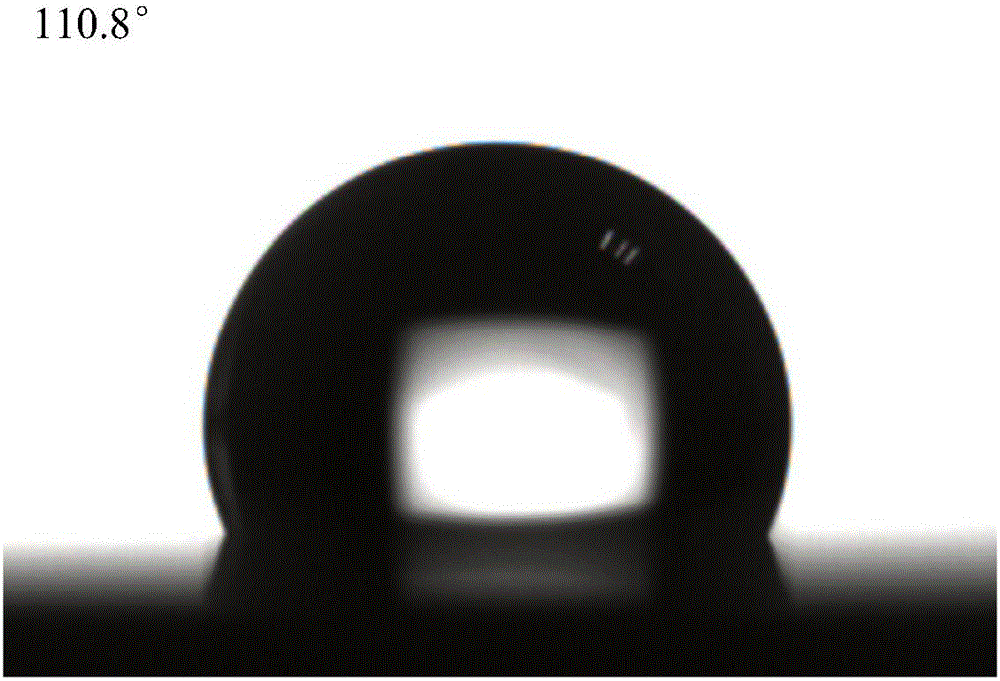

[0035] The main difference between this embodiment and embodiment 1 is that the reaction temperature is 85° C., and the rest of the steps are the same as in embodiment 1.

Embodiment 3

[0037] The main difference between this embodiment and embodiment 1 is that the reaction temperature is 115° C., and the rest of the steps are the same as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com