Polyacetylenic compound and preparation method thereof

A technology of compound and polyalkyne amine, which is applied in the field of polyalkyne amine compounds and the preparation of the polyalkyne amine compounds by reacting alkyne halides and sulfonamides, achieving the effects of good application value, simple preparation method and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of polyalkyne amine compound P1, its structural formula is as follows:

[0037]

[0038] The polyalkyne amine compound is prepared by reacting an alkyne halide with a sulfonamide monomer, and its specific reaction equation is as formula (1):

[0039]

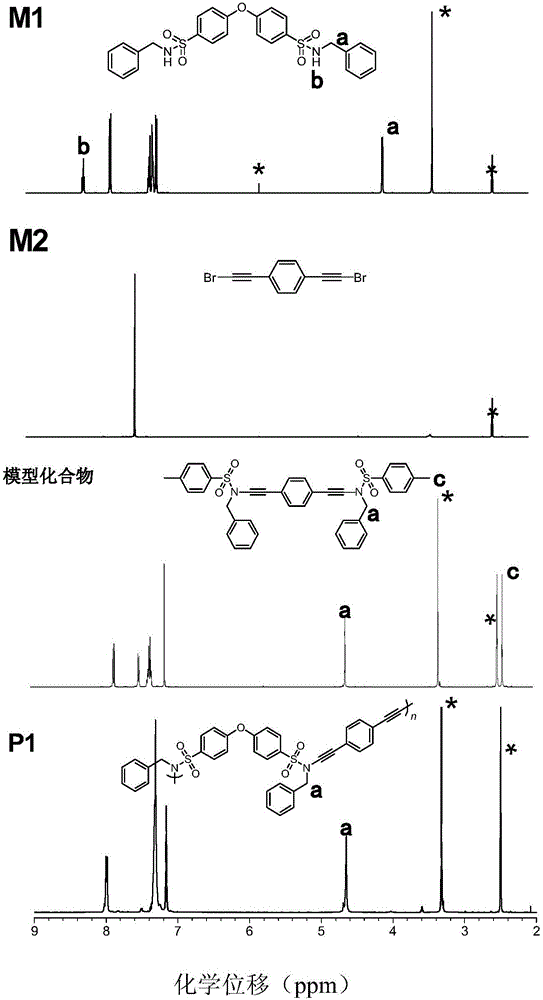

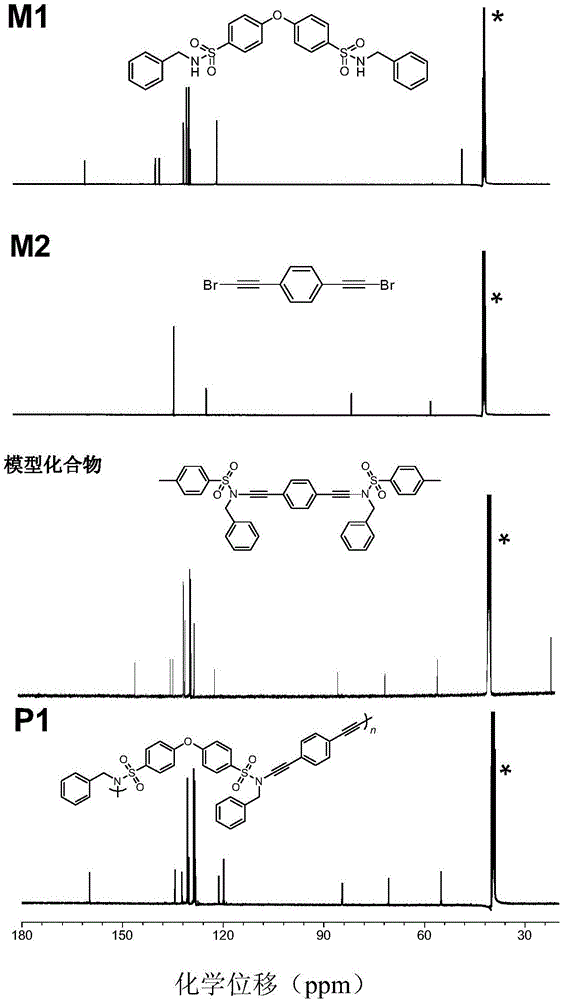

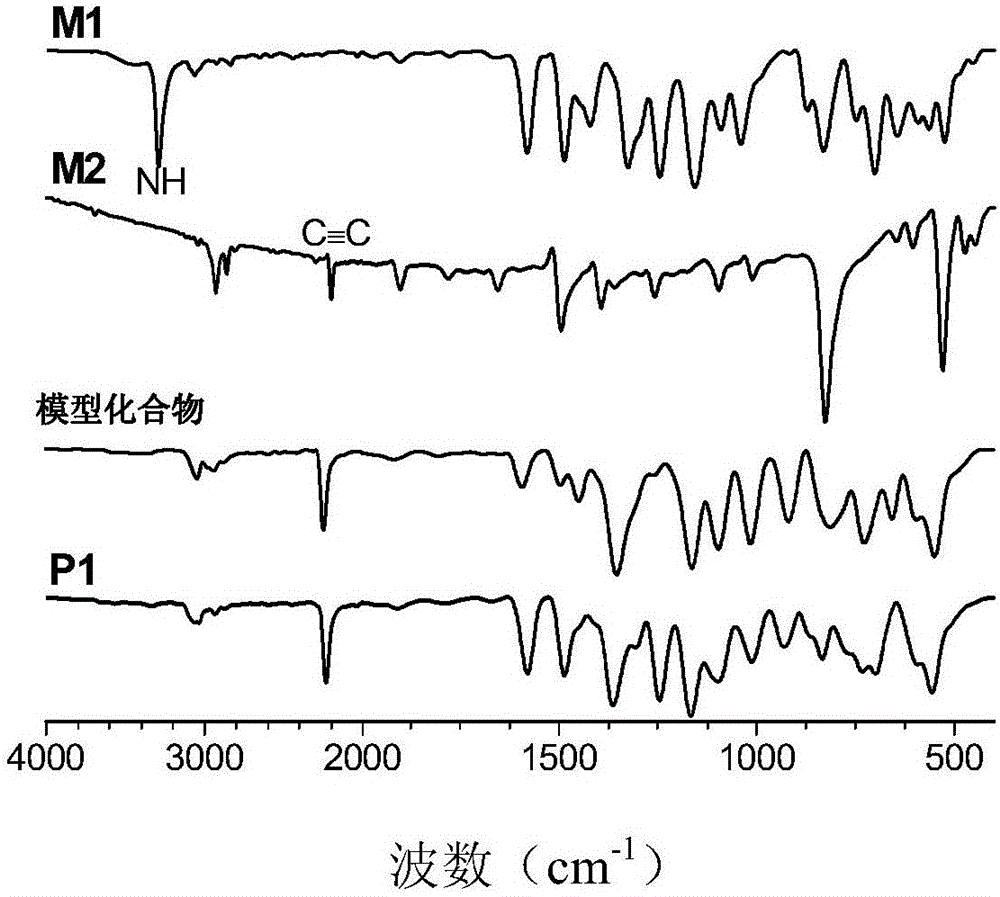

[0040] (1) The synthesis method of monomer M1 is: at 0°C, add 9.0mmol (3.29g) of sulfonyl chloride into a 250mL two-necked bottle, vacuumize and replace N 2 After adding 150mL of dichloromethane and 36.9mmol (4.03mL) benzylamine, the reaction system was stirred at room temperature for 2 hours, extracted three times with dichloromethane and water, spin-dried, and the crude product was separated and purified by silica gel chromatography Vacuum drying at 40°C gave 7.7 mmol (3.90 g) of product (monomer M1) with a yield of 85%; figure 1 8.20 of the M1 monomer in the NMR diagram is -NH peak, and 4.04 is -CH 2 Peak, wherein, 3.32 is water peak, and 2.50 is DMSO-d6 peak; image 3 There is a -NH peak in monomer M1;...

Embodiment 2

[0048] In this example, the reaction time in Example 1 was changed to 80° C., and other preparation conditions were the same as in Example 1 to obtain 0.13 g of polymer with a yield of 90% and a molecular weight of 17000 g / mol.

Embodiment 3

[0050] In this embodiment, the CuSO in embodiment 1 4 ·5H 2 O feed intake is changed into 0.04mmol (0.007g), 1,10-phenanthroline feed intake is changed into 0.08mmol (0.02g), K 2 CO 3 The feeding amount was changed to 0.80 mmol (0.11 g), and the other preparation conditions were the same as in Example 1 to obtain 0.12 g of polymer with a yield of 81% and a molecular weight of 18000 g / mol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com