Preparation method and device of polyvinyl chloride plastic dipping fluid

A technology of polyvinyl chloride and dipping liquid, which is applied in the process of subatmospheric pressure and pressure vessels used in chemical processes, etc., can solve the problems of poor quality of dipping liquid and high preparation cost, and achieve the reduction of film forming temperature and initial Enhanced viscosity and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A preparation method for polyvinyl chloride dipping solution, comprising the steps of:

[0021] (1) take by weight neoprene latex 20kg, PVC paste resin 90kg, calcium carbonate 30kg, defoamer 0.5kg, stabilizer 0.2kg, viscosity reducer 8kg, sodium dodecylbenzenesulfonate 0.5kg, 12kg of pigment, 1kg of anti-ultraviolet agent and 2kg of zinc oxide;

[0022] (2) The chloroprene latex, defoamer, stabilizer, viscosity reducer, emulsifier, anti-ultraviolet agent and zinc oxide that step (1) takes by weighing are added in the stirring tank together, stir 0.5 hour;

[0023] (3) Next, add the PVC paste resin, calcium carbonate and colorants weighed in step (1) into the stirring tank together, and stir for 1 hour under ultrasonic conditions to obtain the PVC dipping liquid.

Embodiment 2

[0025] A preparation method for polyvinyl chloride dipping solution, comprising the steps of:

[0026] (1) take by weight neoprene latex 25kg, PVC paste resin 100kg, calcium carbonate 35kg, defoamer 6kg, stabilizer 3kg, viscosity reducer 9kg, sodium lauryl sulfate 1.2kg, colorant 13kg, Anti-ultraviolet agent 2kg and zinc oxide 5kg;

[0027] (2) The chloroprene latex, defoamer, stabilizer, viscosity reducer, emulsifier, anti-ultraviolet agent and zinc oxide that step (1) takes by weighing are added in the stirred tank together, stir 0.8 hour;

[0028] (3) Then add the PVC paste resin, calcium carbonate and colorant weighed in the step (1) into the stirring tank together, and stir for 1.5 hours under ultrasonic conditions to obtain the PVC dipping solution.

Embodiment 3

[0030] (1) take by weight neoprene latex 30kg, PVC paste resin 120kg, calcium carbonate 40kg, defoamer 8kg, stabilizer 5kg, viscosity reducer 10kg, secondary alkane sulfonate sodium 2kg, colorant 15kg, Anti-ultraviolet agent 3kg and zinc oxide 8kg;

[0031] (2) The chloroprene latex, defoamer, stabilizer, viscosity reducer, emulsifier, anti-ultraviolet agent and zinc oxide that step (1) takes by weighing are added in the stirring tank together, stir 1 hour;

[0032] (3) Next, add the PVC paste resin, calcium carbonate and colorant weighed in step (1) into the stirring tank together, and stir for 2 hours under ultrasonic conditions to obtain the PVC dipping solution.

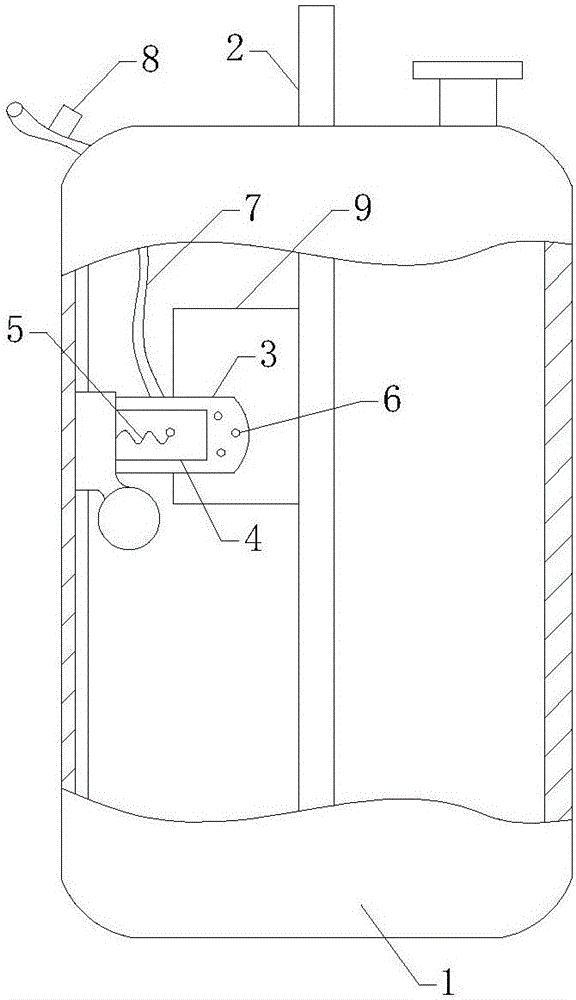

[0033] The dipping solution preparation device of the present invention will be described in detail below in conjunction with the accompanying drawings, as figure 1 Shown: a device for preparing dipping liquid, including a stirring tank, the stirring tank includes a tank body 1 and a stirring shaft 2, the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com