Heat-resisting interpenetrating polymer network plural gel profile control agent and preparation method thereof

An interpenetrating network and composite gel technology, which is applied in the field of high temperature resistant interpenetrating network composite gel profile control agent and its preparation, can solve the problems of unfavorable oil field operation injection, uneven mixing of working fluid, short polymerization reaction time, etc. , to achieve significant social and economic efficiency, make up for the uncontrolled gelation time, and the effect of long gelation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the high temperature resistant interpenetrating network composite gel profile control agent of the present invention comprises the following steps:

[0042] (1) Mix water glass, auxiliary agent I, auxiliary agent II and water at normal temperature and pressure;

[0043] (2) Add the solution prepared in step (1) to the polymer, and after stirring evenly, add the solution of crosslinking agent I and crosslinking agent II;

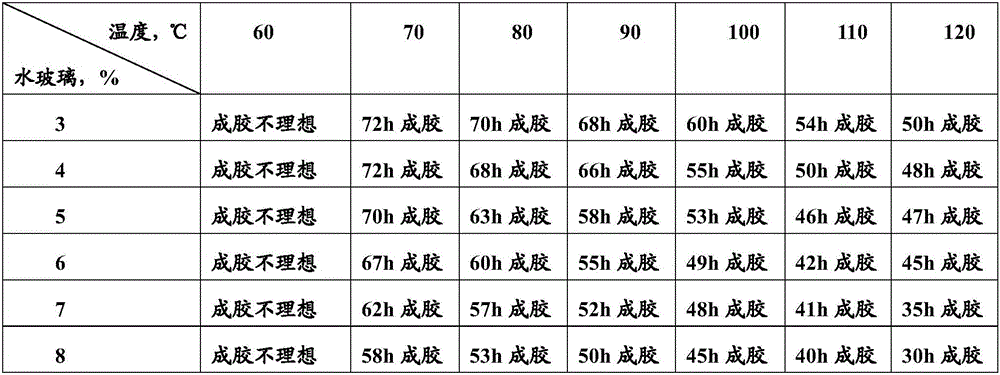

[0044] (3) Put the reaction solution in step (2) at high temperature to carry out polymerization reaction for 28-72h.

[0045] In one embodiment of the present invention, stirring is carried out for 30-90 minutes in step (2).

[0046] In one embodiment of the present invention, in step (3), the temperature is 80°C-120°C.

[0047] In the present invention, unless otherwise stated, the operation is carried out at normal temperature and pressure.

[0048] In the present invention, unless otherwise stated, all parts and percent...

Embodiment 1

[0056] Mix 3g of sodium silicate, 1g of sodium bentonite, 1g of silicate, and 100g of water at normal temperature and pressure, then add 0.1g of polymer hydrolyzed polyacrylamide to the prepared solution, stir for 45 minutes, and then add 1g of methyl acetate ester, 0.1 g of phenolic resin cross-linking agent solution, and the reaction solution was placed at a temperature of 90° C. for 68 hours of polymerization.

Embodiment 2

[0060] Mix 8g of sodium silicate, 1g of sodium bentonite, 1g of silicate and 100g of water at normal temperature and pressure, then add 0.1g of polymer hydrolyzed polyacrylamide to the prepared solution, stir for 45 minutes, and then add 1g of methyl acetate ester, 0.1 g of phenolic resin cross-linking agent solution, and the reaction solution was polymerized at 90° C. for 50 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com