Preparation method of peeled rapeseed oil

A technology of rapeseed oil and rapeseed, which is applied in the field of preparation of dehulled rapeseed oil, can solve problems affecting the development and utilization of rapeseed cake, increase the color of crude oil, and reduce the quality of oil, so as to increase the use value and improve the color Appearance, effect of improving oil quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

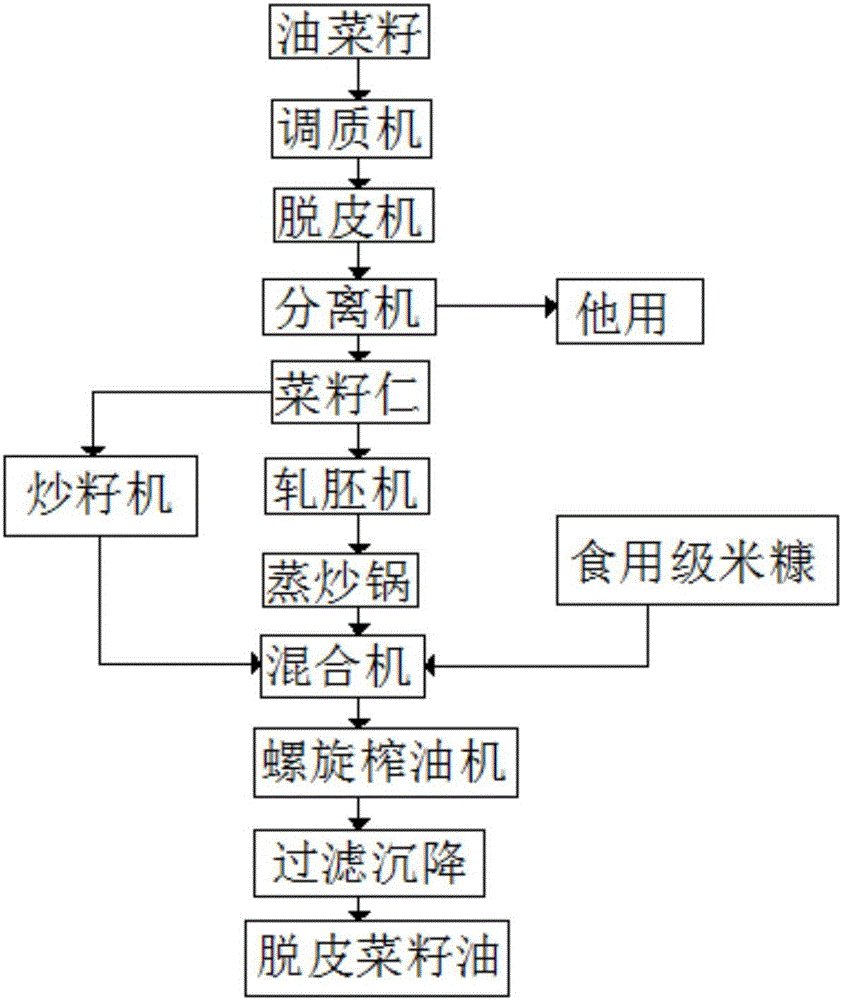

Image

Examples

Embodiment 1

[0021] A preparation method of dehulled rapeseed oil, comprising the steps of:

[0022] S1. Screen and remove impurities. Select a certain amount of rapeseed according to the storage capacity of the pre-used equipment for screening. After removing impurities, make the rapeseed contain less than 0.5% of impurities, and then transfer the rapeseed to a container for cleaning. Then put it into the conditioning machine, adjust the water content of rapeseed to 8% and set aside;

[0023] S2, peeling, the rapeseed after conditioning in S1 is transferred to a peeling machine for peeling treatment;

[0024] S3, separation, the rapeseed after the peeling treatment in S2 is separated from the skin and kernel by winnowing, the peeling rate is ≥ 80%, the skin content in the kernel is ≤ 5%, the kernel content in the skin is ≤ 1%, and the obtained skin For other purposes, such as leaching oil, as a fungal culture medium or as a fuel, the obtained rapeseed kernels are ready to be put into a c...

Embodiment 2

[0031] A preparation method of dehulled rapeseed oil, comprising the steps of:

[0032] S1. Screen and remove impurities. Select a certain amount of rapeseed according to the storage capacity of the pre-used equipment for screening. After removing impurities, make the rapeseed contain less than 0.5% of impurities, and then transfer the rapeseed to a container for cleaning. Then put it into the conditioning machine, adjust the water content of rapeseed to 9% and set aside;

[0033] S2, peeling, the rapeseed after conditioning in S1 is transferred to a peeling machine for peeling treatment;

[0034] S3, separation, the rapeseed after the peeling treatment in S2 is separated from the skin and kernel by winnowing, the peeling rate is ≥ 80%, the skin content in the kernel is ≤ 5%, the kernel content in the skin is ≤ 1%, and the obtained skin For other purposes, such as leaching oil, as a fungal culture medium or as a fuel, the obtained rapeseed kernels are ready to be put into a c...

Embodiment 3

[0041] A preparation method of dehulled rapeseed oil, comprising the steps of:

[0042] S1. Screen and remove impurities. Select a certain amount of rapeseed according to the storage capacity of the pre-used equipment for screening. After removing impurities, make the rapeseed contain less than 0.5% of impurities, and then transfer the rapeseed to a container for cleaning. Then put it into the conditioning machine, adjust the water content of rapeseed to 9% and set aside;

[0043] S2, peeling, the rapeseed after conditioning in S1 is transferred to a peeling machine for peeling treatment;

[0044] S3, separation, the rapeseed after the peeling treatment in S2 is separated from the skin and kernel by winnowing, the peeling rate is ≥ 80%, the skin content in the kernel is ≤ 5%, the kernel content in the skin is ≤ 1%, and the obtained skin For other purposes, such as leaching oil, as a fungal culture medium or as a fuel, the obtained rapeseed kernels are ready to be put into a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com