System and method for processing rare earth concentrates

A rare earth concentrate and rare earth technology, applied in the system field of rare earth concentrate processing, can solve the problems of large amount of caustic soda, a large amount of acid dissolution, three wastes, etc., and achieve the effects of low cost, reduced dilution, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

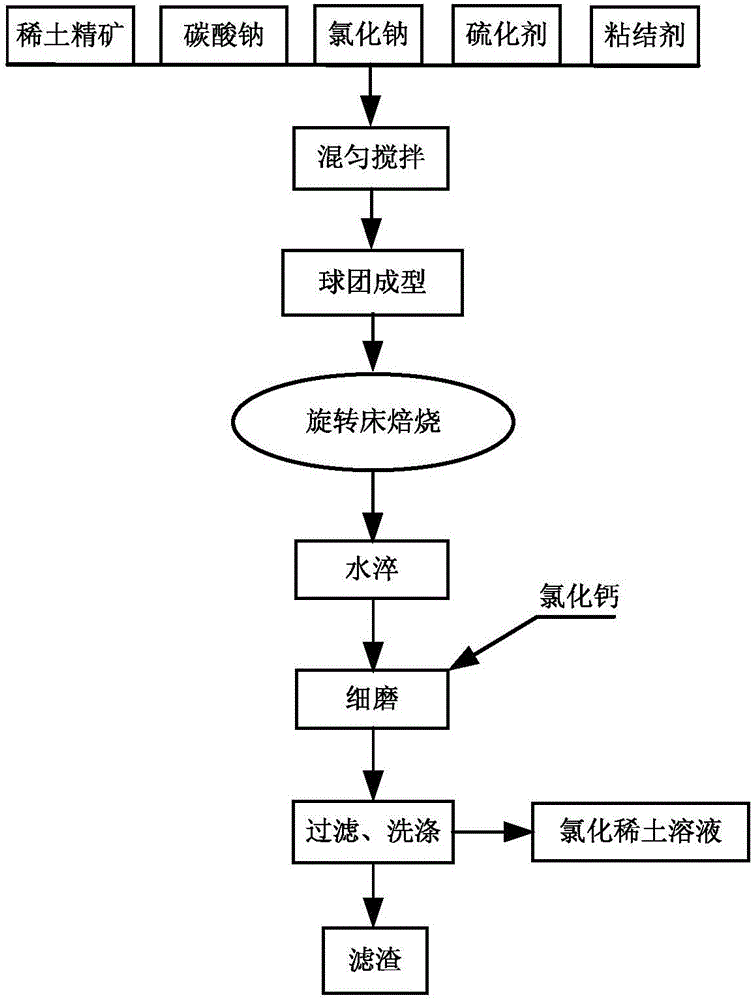

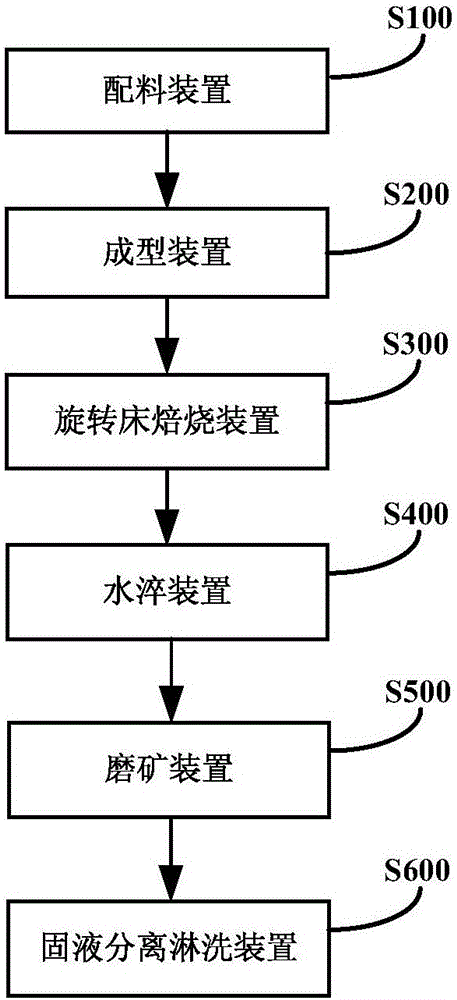

[0041] reference figure 1 with figure 2 , The weight ratio of phosphate ore rare earth concentrate, sodium carbonate, sodium chloride, pyrite concentrate (sulfide agent), and sodium humate (binder) with a REO content of 20% is 100:20:30 :2:5 Mix the ingredients in the batching device S100 and prepare pellets in the forming device S200 to prepare rare earth green pellets with a particle size of 12mm-16mm, and the pellets contain 2% water. The rare earth green pellets are roasted using a rotating bed roasting device S300, the roasting temperature is 900°C, and the residence time of the pellets in the rotating bed roasting device S300 is 30 minutes. Rotating bed roasting device S300 adopts gas radiant tube for closed radiant heating, and the air pressure in the furnace is controlled to be micro negative pressure -30pa~-50pa. After roasting, the hot pellets are directly sent from the rotating bed roasting device S300 to the water quenching device S400 for water quenching. 1% by w...

Embodiment 2

[0043] reference figure 1 with figure 2 , The fluorocarbonate rare earth concentrate, sodium carbonate, sodium chloride, sulfur (vulcanizing agent), sodium humate (binder) with a REO content of 48% are in a weight ratio of 100:5:100:30 : 7 Mix the ingredients in the batching device S100 and prepare pellets in the forming device S200 to prepare rare earth green pellets with a particle size of 8mm-12mm, and the pellets contain 3% water. The rare earth green pellets are roasted using a rotating bed roasting device S300, the roasting temperature is 800°C, and the residence time of the pellets in the rotating bed roasting device S300 is 60 minutes. Rotating bed roasting device S300 adopts gas radiant tube for closed radiant heating, and the air pressure in the furnace is controlled to a slight negative pressure of -10pa~-20pa. After roasting, the hot pellets are directly sent from the rotating bed roasting device S300 to the water quenching device S400 for water quenching, and 5% ...

Embodiment 3

[0045] reference figure 1 with figure 2 , Put the mixed rare earth concentrate, sodium carbonate, sodium chloride, sulfur (vulcanizing agent), and modified starch (binder) with a REO content of 60% in a weight ratio of 100:35:100:30:10 in the batching device The ingredients in S100 are mixed uniformly and pellets are prepared in the forming device S200 to prepare rare earth green pellets with a particle size of 6-10 mm, and the pellets contain 4% water. The rare earth green pellets are roasted using a rotating bed roasting device S300, the roasting temperature is 600°C, and the residence time of the pellets in the rotating bed roasting device S300 is 80 minutes. Rotating bed roasting device S300 adopts gas radiant tube for closed radiant heating, and the air pressure in the furnace is controlled to a slight negative pressure of -5pa~-10pa. After roasting, the hot pellets are directly sent from the rotating bed roasting device S300 to the water quenching device S400 for water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com