Wheel steel with tensile strength being at level of 590 MPa and production method

A technology of tensile strength and production method, applied in the field of metallurgy, which can solve the problems of bursting, large-sized oxides and nitrides, cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

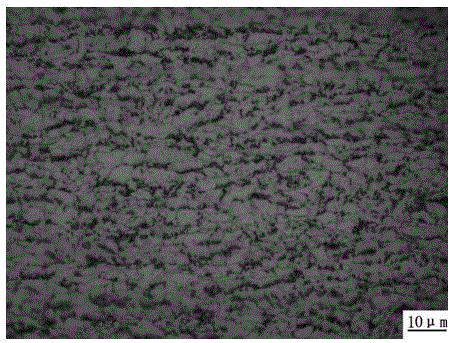

Image

Examples

Embodiment 1

[0029] A wheel steel with a tensile strength of 590MPa, the chemical composition and weight percentage are: C: 0.05%, Si: 0.1%, Mn: 1.4%, P: 0.015%, S: 0.008%, Nb: 0.04%, O: 0.0025% , N: 0.0040%, Als: 0.015%, the balance is Fe and unavoidable impurities.

[0030] Using 150 tons of converter smelting, LF refining, slab continuous casting, heating, high pressure water descaling, controlled rolling (rough rolling→hot coil box→finish rolling), controlled rolling cooling, coiling production process,

[0031] The micro-positive pressure in the LF refining process ensures deoxidation and desulfurization, outbound [O]: 20ppm, [N]: 30ppm; the slab continuous casting process performs large and medium ladle protection to prevent inhalation oxidation, product requirements [O]: 25ppm, [ N]: 40ppm.

[0032] Qualified slabs are heated to 1300°C, the exit temperature of the 5th pass of rough rolling is 1140°C, the exit temperature of the 7th pass of finish rolling is 890°C after passing thro...

Embodiment 2

[0034] A wheel steel with a tensile strength of 590MPa, the chemical composition and weight percentage are: C: 0.06%, Si: 0.08%, Mn: 1.5%, P: 0.013%, S: 0.006%, Nb: 0.045%, O: 0.0023% , N: 0.0038%, Als: 0.019%, the balance is Fe and unavoidable impurities.

[0035] It adopts 150-ton converter smelting, LF refining, slab continuous casting, heating, high-pressure water descaling, controlled rolling (rough rolling→finish rolling), controlled rolling cooling, and coiling production processes.

[0036] The micro-positive pressure in the LF refining process ensures deoxidation and desulfurization, outbound [O]: 18ppm, [N]: 33ppm; the slab continuous casting process performs large and medium ladle protection to prevent inhalation oxidation, product requirements [O]: 23ppm, [ N]: 38ppm.

[0037] The qualified slab is heated to 1250°C, the exit temperature of the 5th pass of rough rolling is 1090°C, the exit temperature of the 7th pass of finish rolling is 870°C, after cooling at 28°...

Embodiment 3

[0039] A wheel steel with a tensile strength of 590MPa, the chemical composition and weight percentage are: C: 0.07%, Si: 0.07%, Mn: 1.6%, P: 0.012%, S: 0.005%, Nb: 0.050%, O: 0.0022% , N: 0.0037%, Als: 0.023%, the balance is Fe and unavoidable impurities.

[0040] It adopts 150-ton converter smelting, LF refining, slab continuous casting, heating, high-pressure water descaling, controlled rolling (rough rolling→hot coil box→finish rolling), controlled rolling cooling, and coiling production processes.

[0041] The micro-positive pressure in the LF refining process ensures deoxidation and desulfurization, outbound [O]: 10ppm, [N]: 35ppm; the slab continuous casting process performs large and medium ladle protection to prevent inhalation oxidation, product requirements [O]: 22ppm, [ N]: 37ppm.

[0042] The qualified slab is heated to 1280°C, the exit temperature of the 5th pass of rough rolling is 1110°C, the exit temperature of the 7th pass of finish rolling is 850°C, after c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com