Starch textile sizing agent for replacing PVA (polyvinyl alcohol)

A technology for textile sizing and sizing, which is applied in the fields of textile sizing and starch textile sizing, can solve the problem that the performance needs to be further improved, and achieve the effects of large elasticity of sizing film, simple preparation method and high thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of starch textile size that replaces PVA, described size is prepared by following raw material by weight:

[0046]

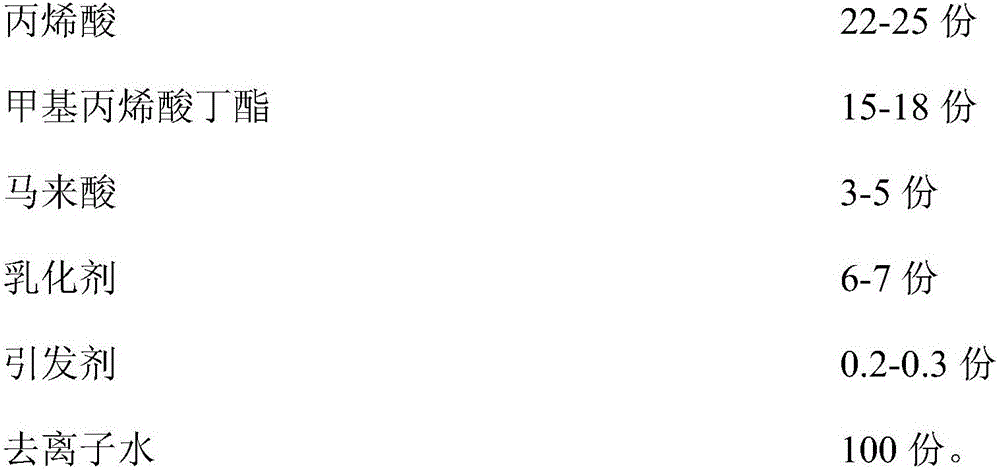

[0047] Wherein, the polyacrylate emulsion is prepared from the following raw materials in parts by weight:

[0048]

[0049]

[0050] Described emulsifier is sodium lauryl sulfate.

[0051] The initiator is ammonium persulfate.

[0052] The defoamer is simethicone.

[0053] The composite modified starch is prepared by the following method: mix wheat starch and tapioca starch with a mass ratio of 1:1 and 100 parts of water into a slurry, add sodium hypochlorite solution, use NaOH to control the pH to 9.0, and oxidize at 30°C for 3 Hours; after the reaction is completed, cool the material to 25°C, add sodium metabisulfite solution to reduce the residual oxidant; then add acetic anhydride to the reaction mass for esterification, use NaOH to control the pH to 7, react at 30°C for 3 hours, and the reaction is complete Finally, use NaOH to ad...

Embodiment 2

[0058]A kind of starch textile size that replaces PVA, described size is prepared by following raw material by weight:

[0059]

[0060]

[0061] Wherein, the polyacrylate emulsion is prepared from the following raw materials in parts by weight:

[0062]

[0063] The emulsifier is OP-10.

[0064] The initiator is ammonium persulfate.

[0065] The defoamer is simethicone.

[0066] The composite modified starch is prepared by the following method: mix wheat starch and tapioca starch with a mass ratio of 1:2 and 100 parts of water into a slurry, add sodium hypochlorite solution, use NaOH to control the pH to 9.0, and oxidize at 40°C for 4 Hours; after the reaction is completed, cool the material to 30°C, add sodium metabisulfite solution to reduce the residual oxidant; then add acetic anhydride to the reaction mass for esterification, use NaOH to control the pH to 7, react at 35°C for 5 hours, and the reaction is complete Finally, use NaOH to adjust the pH value of th...

Embodiment 3

[0071] A kind of starch textile size that replaces PVA, described size is prepared by following raw material by weight:

[0072]

[0073] Wherein, the polyacrylate emulsion is prepared from the following raw materials in parts by weight:

[0074]

[0075] The emulsifier is sodium lauryl sulfate and OP-10 with a volume ratio of 1:1.

[0076] The initiator is ammonium persulfate.

[0077] The defoamer is simethicone.

[0078] The composite modified starch is prepared by the following method: mix wheat starch and tapioca starch with a mass ratio of 1:1.5 and 100 parts of water into a slurry, add sodium hypochlorite solution, use NaOH to control the pH to 9.0, and oxidize at 32°C for 3.5 Hours; after the reaction is completed, cool the material to 28°C, add sodium metabisulfite solution to reduce the residual oxidant; then add acetic anhydride to the reaction mass for esterification, use NaOH to control the pH to 7, react at 33°C for 4 hours, and the reaction is complete ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com