Environment-friendly cupola

A cupola, environmentally friendly technology, applied in the field of metallurgical casting for metal smelting, can solve the problems of air pollution, unable to keep up, hinder the survival and development of foundry enterprises, etc., and achieve the effect of low cost of modification, simple and effective structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

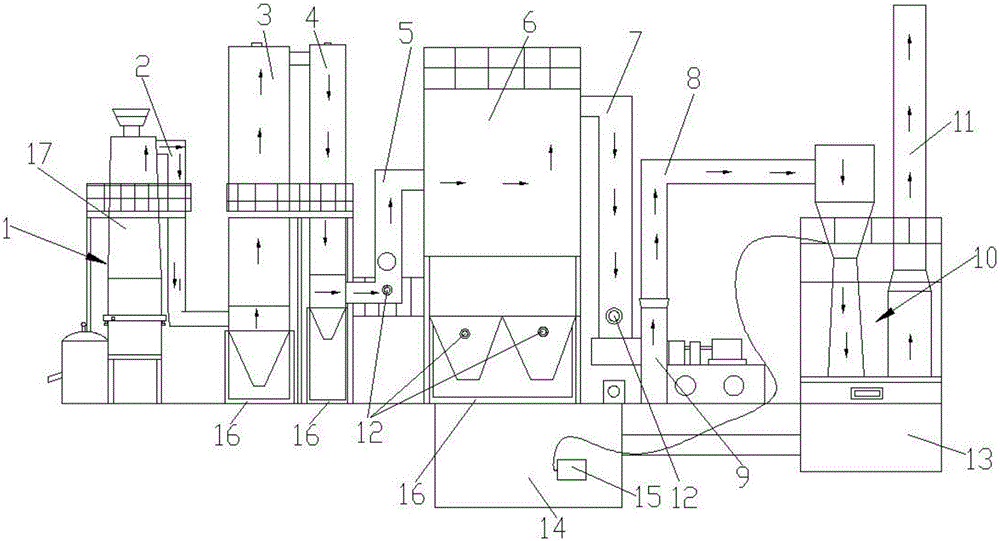

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0015] as attached figure 1 The shown a kind of environmental protection cupola of the present invention comprises a cupola body 1 and a waste gas treatment device connected thereto; the cupola body 1 includes a flue gas chamber 17; the side of the flue gas chamber 17 passes through the first The flue gas pipe 2 communicates with the waste gas treatment device; the waste gas treatment device includes a large cooler 3, a small cooler 4, a second flue gas pipe 5, a bag filter 6, a third flue gas pipe 7, and a fourth flue gas pipe 8, induced draft fan 9, spray desulfurization device and chimney 11; the upper and lower ends of the large cooler 3 communicate with the small water cooler 4 and the first flue gas pipe 2 respectively; the lower part of the small water cooler 4 The second flue gas pipe 5 is connected to the inlet of the bag fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com