Micro-mechanical resonant electrometer with ultra-high sensitivity

An electrometer and micro-mechanical technology, applied in the measurement of electrical variables, measuring devices, instruments, etc., can solve the problem of insufficient sensitivity and resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

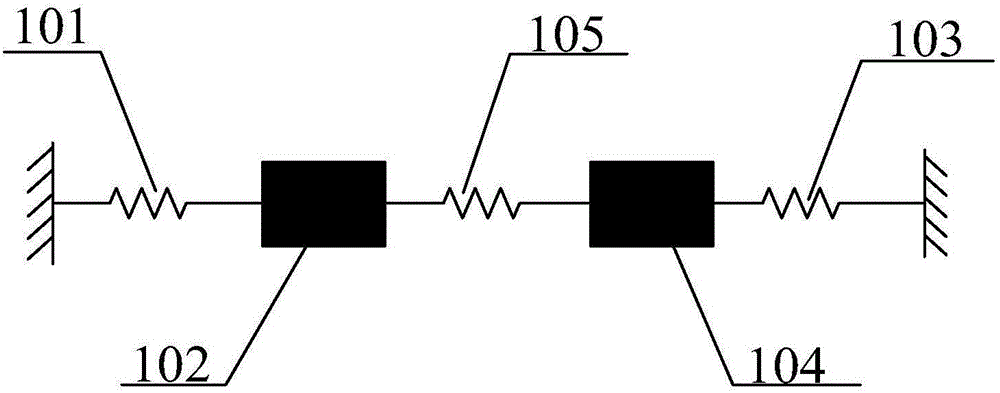

Problems solved by technology

Method used

Image

Examples

Embodiment 1

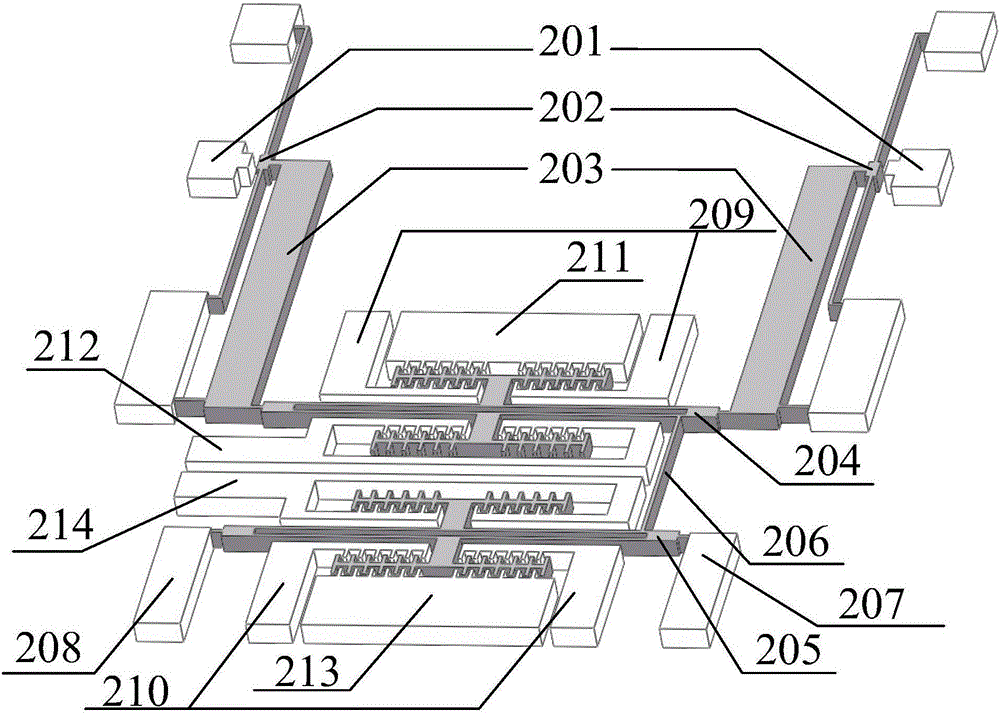

[0033] Example 1: figure 2 A mechanical structure of a MEMS resonant electrometer is given, and its resonator is a double-ended fixed tuning fork (DETF) structure.

[0034] The structure of the electrometer in this embodiment is as follows: the electrometer includes two charge input gate electrodes 201 placed symmetrically, and two movable parallel plates 202 are arranged correspondingly with the two gate electrodes 201, each forming a tiny gate Capacitor; two movable parallel plates 202 are respectively connected to the support beams at both ends of the resonator I 204 through a micromechanical lever 203; the resonator I 204 is a double-ended fixed tuning fork structure, that is, both ends of two identical elastic beams are fixed After that, they are respectively connected with the support beams to form a structure like a tuning fork; another identical resonator II 205 is connected to the resonator I 204 through a mechanical coupling beam 206; the position of the mechanical co...

Embodiment 2

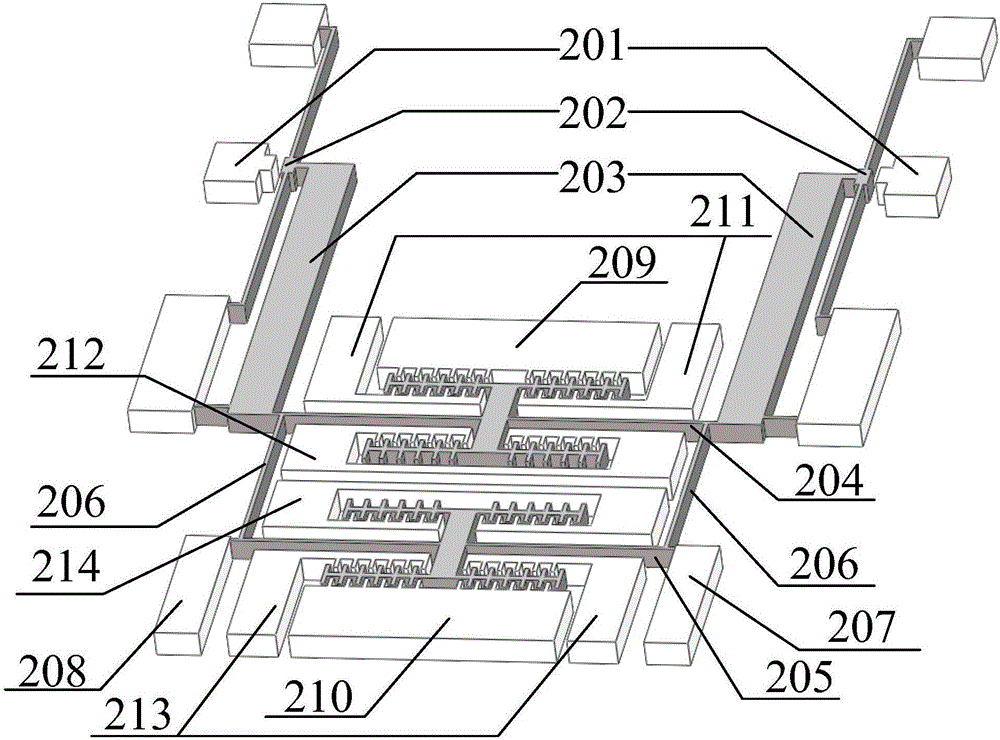

[0044] Example 2: image 3 Another mechanical structure of the micromechanical resonant electrometer according to the present invention is given, the resonator of which is a single beam structure.

[0045] The structure of the electrometer in this embodiment is as follows: the electrometer includes two charge input gate electrodes 201 placed symmetrically, and two movable parallel plates 202 are arranged correspondingly with the two gate electrodes 201, each forming a tiny gate capacitor; two movable parallel plates 202 are respectively connected to both ends of the resonator I 204 through a micromechanical lever 203; The same resonator II 205 is connected to the resonator I 204 through two mechanical coupling beams 206; the position of the mechanical coupling beam 206 is close to the end of the resonator, which can realize weak coupling; the two ends of the resonator II 205 are respectively connected to the DC drive electrode I 207 and the On the DC driving electrode II 208,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com