Capping layer, OLED display panel comprising capping layer and electronic device

A display panel and cover layer technology, applied in circuits, electrical components, electrical solid devices, etc., can solve problems such as unsatisfactory light extraction efficiency of devices, ensure overall light extraction efficiency, improve film formation stability and optical performance, and improve transparency. light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] Exemplary as A preparation method comprising the steps of:

[0061]

[0062] When B is selected from any one of substituted or unsubstituted C5-C10 cycloalkyl, substituted or unsubstituted C6-C30 aromatic groups with at least 2 broken bonds, it can be prepared by the following method:

[0063]

Embodiment 1

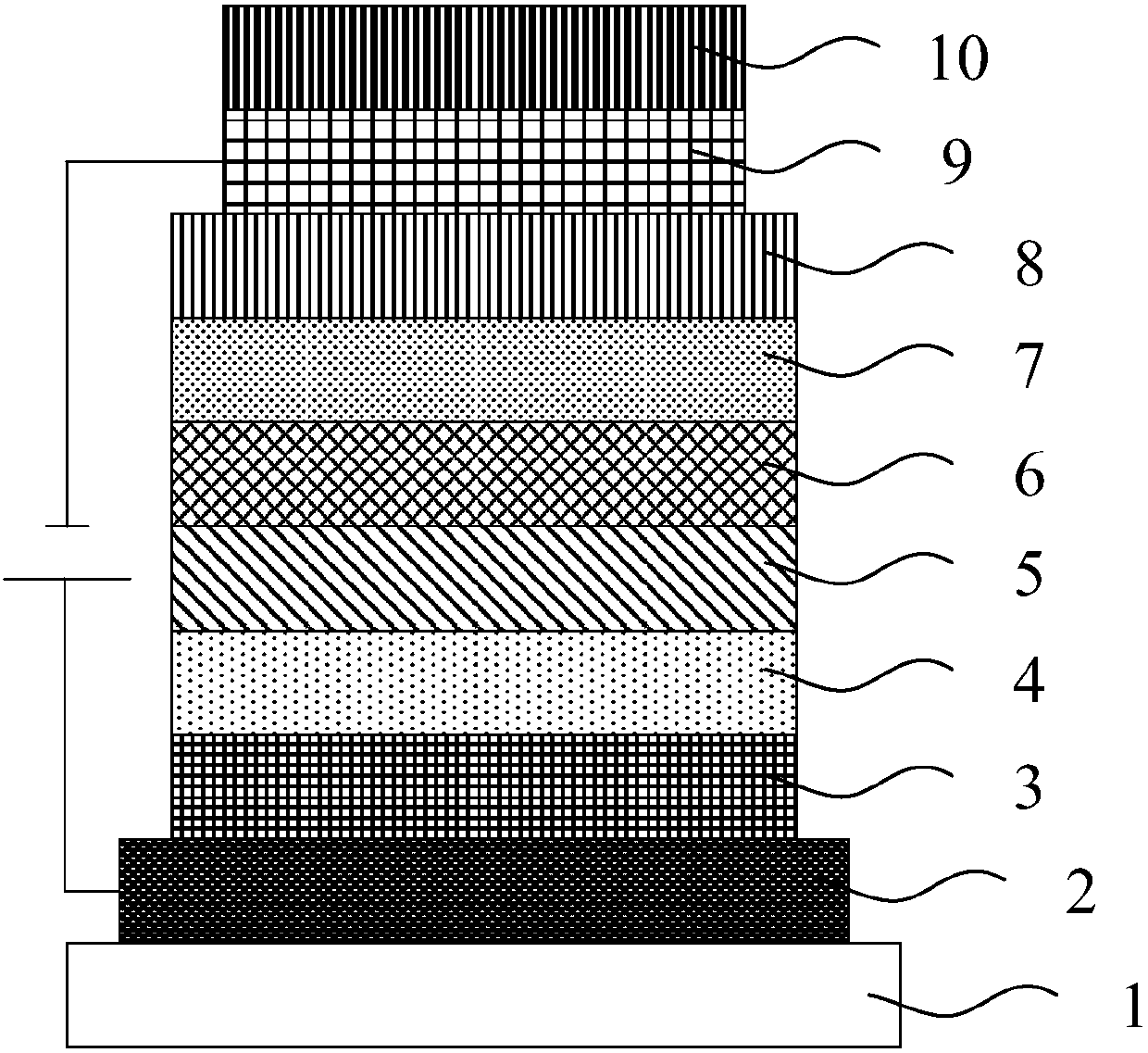

[0066] figure 1 An OLED display panel S1 is provided, including the following structure from bottom to top:

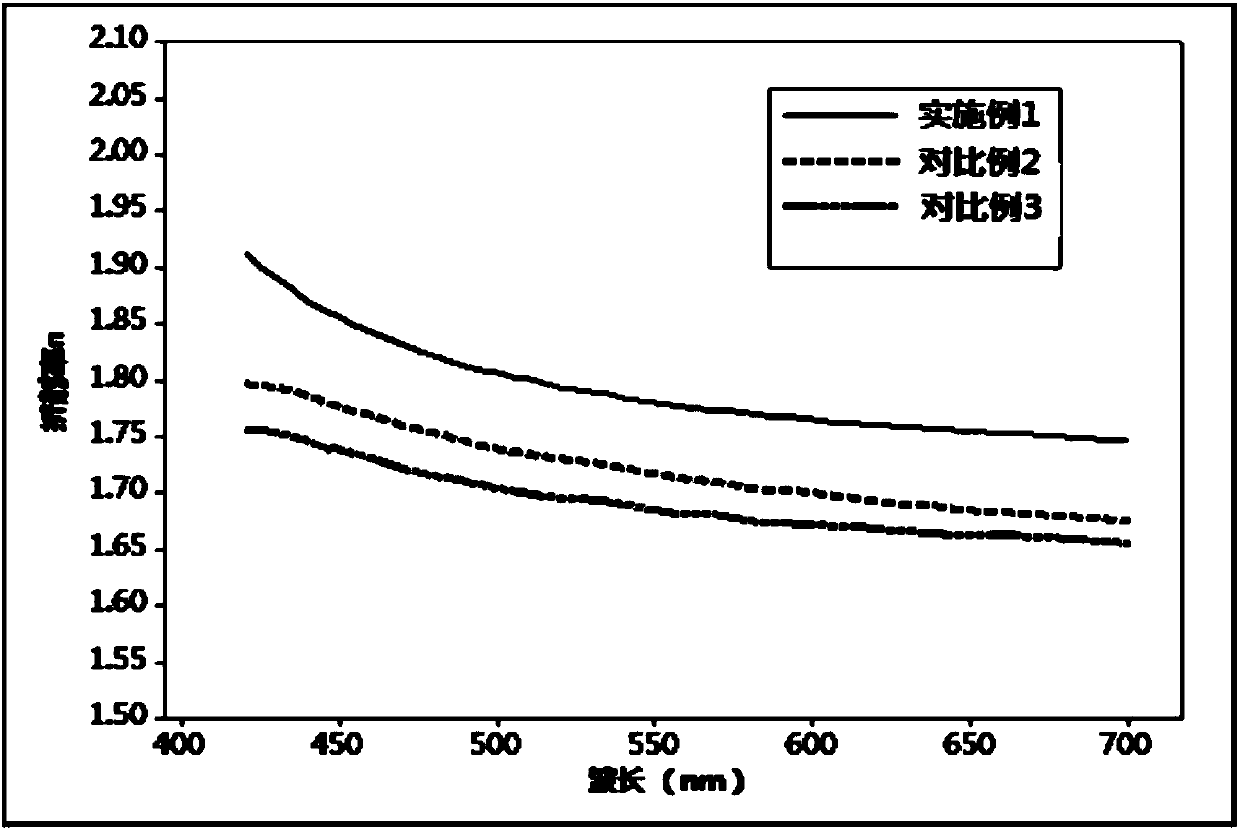

[0067] Substrate 1, silver reflective electrode (100nm), ITO electrode 2 (15nm), first hole transport layer 3 (10nm), second hole transport layer 4 (110nm), light emitting layer 6 (30nm), first electron transport layer Layer 7 (30nm), second electron transport layer 8 (5nm), magnesium-silver electrode (magnesium-silver mass ratio 9:1wt) 9 (15nm) and covering layer 10, and described covering layer is passed Obtained by evaporation, the thickness of the covering layer is 70nm, and the refractive index n of the covering layer is 450~650nm >1.76, the refractive index of 450nm, 530nm, 620nm is 1.84, 1.78, 1.76 respectively;

[0068] The first hole transport layer is (P-type dopant material) material and Doping, the mixing ratio is 5:95 (mass ratio); the second hole transport layer is Material; light-emitting layer is BD :BH Materials, 5:95; the first electron t...

Embodiment 2

[0070] The difference from Example 1 is that the material of the covering layer is The thickness of the covering layer is 70nm, and the refractive index n of the covering layer 450~650nm >1.8, the refractive indices of 450nm, 530nm, and 620nm are 1.95, 1.87, and 1.82, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com