Filter medium, method for producing filter medium, water treatment module, and water treatment device

A filter material and substrate technology, applied in water/sludge/sewage treatment, separation methods, fiber treatment, etc., can solve problems such as insufficient anti-pollution, difficult adhesion of oil, and reduced flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[1037] Hereinafter, the effects of the present invention will be further described in detail through examples. In addition, this invention is not limited to an Example.

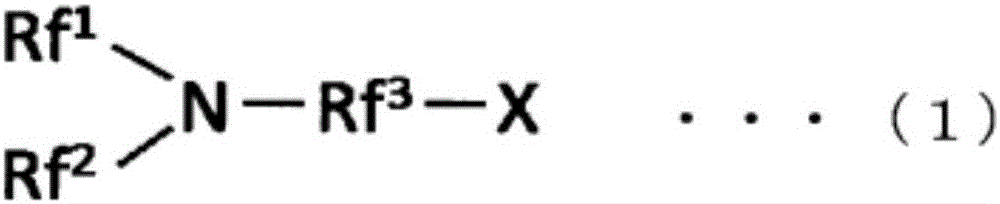

[1038] [Synthesis of Nitrogen-Containing Fluorine Compounds]

Synthetic example 1

[1040] "Synthesis of 2-[3-[[perfluoro(2-methyl-3-dibutylaminopropionyl)]amino]propyl-dimethyl-ammonium]acetate"

[1041] 120 g of perfluoro(2-methyl-3-dibutylaminopropionyl) fluoride obtained by the electrolytic fluorination of methyl 2-methyl-3-dibutylaminopropionate was added dropwise to 39 g of dimethylaminopropylamine was dissolved in a solution of 500 ml of IPE solvent. After stirring at room temperature for 2 hours, filter with NaHCO 3 The isopropyl ether (IPE) layer of the filtrate was washed with an aqueous solution and an aqueous NaCl solution, and washed with water after separating the layers. Then, IPE was removed by distillation, and 64 g (C 4 f 9 ) 2 NCF 2 CF(CF 3 )CONHC 3 h 6 N(CH 3 ) 2 (Yield 47%).

[1042] Next, the resulting 8g (C 4 f 9 ) 2 NCF 2 CF(CF 3 )CONHC 3 h 6 N(CH 3 ) 2 Reflux overnight with sodium monochloroacetate while stirring in ethanol, filter and concentrate to obtain 9 g of dimethyl betaine represented by the following formu...

Synthetic example 2

[1046] "Synthesis of 2-[3-[[perfluoro(3-dibutylaminopropionyl)]amino]propyl-dimethyl-ammonium]acetate"

[1047] 20 g of perfluoro(3-dibutylaminopropionyl) fluoride obtained by the electrolytic fluorination of methyl 3-dibutylaminopropionate was added dropwise to 4 g of dimethylaminopropylamine dissolved in 50 ml of A solution made of IPE solvent. After stirring at room temperature for 2 hours, filter with NaHCO 3 The IPE layer of the filtrate was washed with aqueous solution and NaCl aqueous solution, and washed with water after liquid separation. Then, as a result of IPE being removed by distillation, 14 g (C 4 f 9 ) 2 NC 2 f 4 CONHC 3 h 6 N(CH 3 ) 2 (Yield 60%).

[1048] Next, the obtained 3g (C 4 f 9 ) 2 NC 2 f 4 CONHC 3 h 6 N(CH 3 ) 2After refluxing with sodium monochloroacetate overnight while stirring in ethanol, 3 g of dimethyl betaine represented by formula (377) was obtained (yield 92%).

[1049] [chemical formula 383]

[1050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com