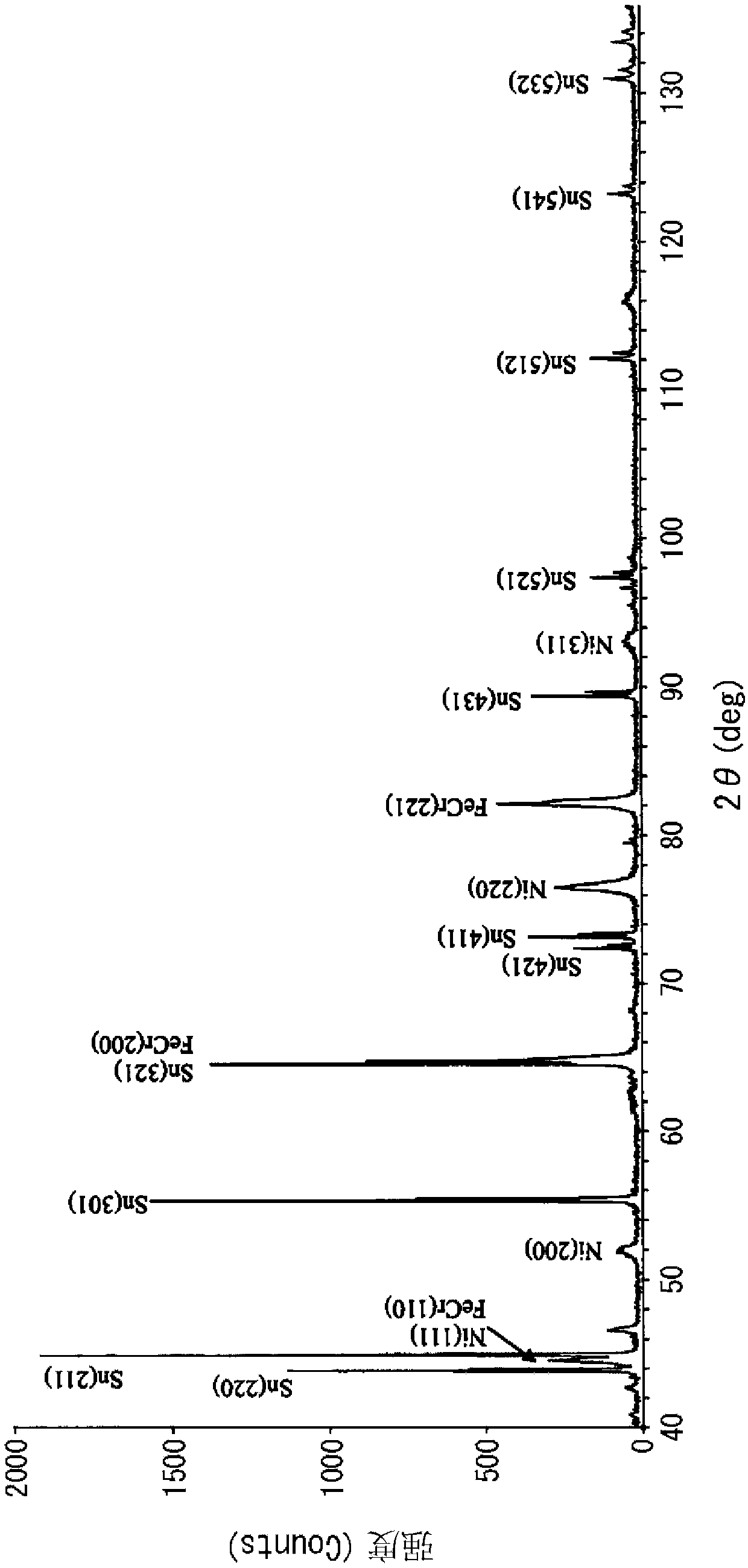

Sn plated stainless steel plate

A stainless steel plate and coating technology, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve different problems and achieve excellent whisker resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

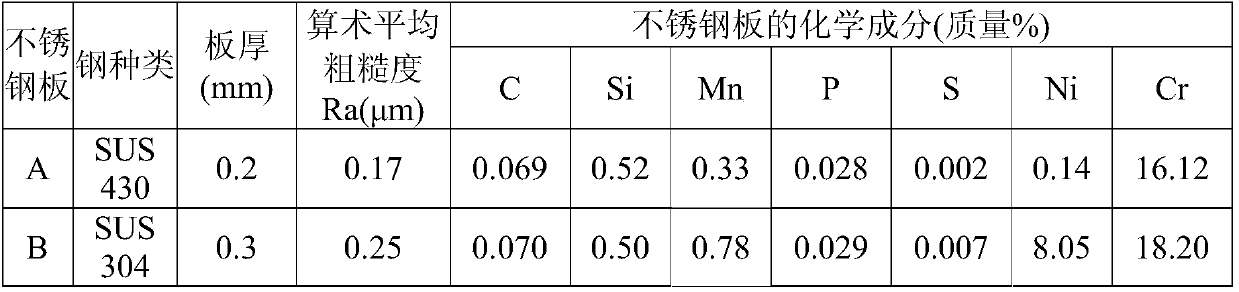

[0050] Using the stainless steel plate A as the stainless steel plate, the stainless steel plate A was acid-washed under the following conditions after performing alkali degreasing on the stainless steel plate A under the following conditions.

[0051] [conditions for alkali degreasing]

[0052] · Degreasing solution: sodium orthosilicate 50g / L

[0053] · Degreasing conditions:

[0054] Liquid temperature: 60°C

[0055] Current density: 5A / dm 2

[0056] Electrolysis time: anode 5 seconds → cathode 5 seconds

[0057] [Conditions of pickling]

[0058] ·Pickling liquid: sulfuric acid 50g / L

[0059] ·Pickling conditions:

[0060] Liquid temperature: 50°C

[0061] Dipping time: 5 seconds

[0062] Next, Ni strike plating was performed on the stainless steel plate A after the pickling under the following conditions, whereby a Ni plating layer with a thickness of 1.0 μm was formed on the stainless steel plate A.

[0063] [Conditions for impact Ni plating]

[0064] Ni platin...

Embodiment 2

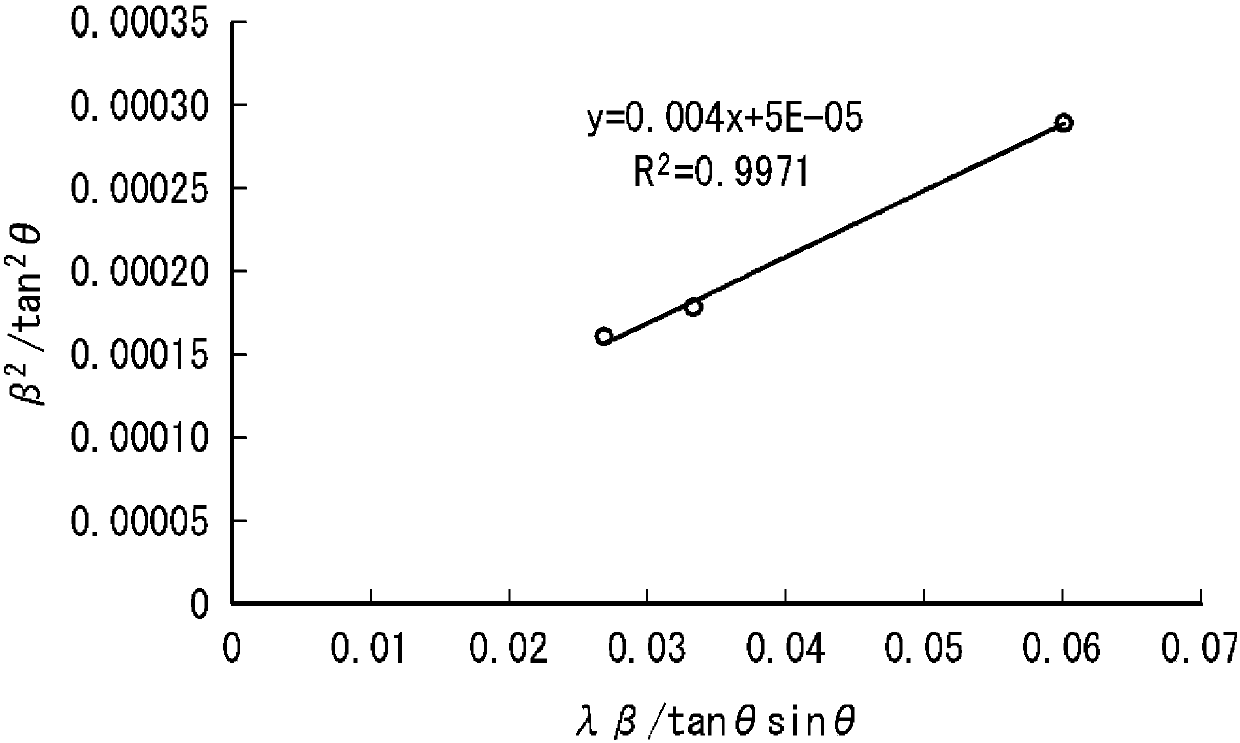

[0097] Like embodiment 1, wherein, use stainless steel plate B as stainless steel plate, change the film thickness of Ni plating layer and the film thickness of Sn plating layer as shown in Table 2, except that, carry out similarly with embodiment 1, make Sn plated stainless steel Plates were carried out in the same manner as in Example 1, and the lattice distortion rate of Ni crystals in the Ni plating layer of the obtained Sn-plated stainless steel plate and the characteristics of the Sn-plated stainless steel plate were examined. List the results in Table 2.

Embodiment 3~8

[0099] As shown in Table 2, using stainless steel plate A or stainless steel plate B as the stainless steel plate, except that the film thickness of the Ni plating layer formed by impact Ni plating was changed to 0.2 μm, it was carried out in the same manner as in Example 1. After forming the Ni strike plating layer on the surface of the plate, as the main Ni plating, Ni plating was performed under the following conditions, and the thickness of the overall Ni plating layer was adjusted as shown in Table 2, thereby forming a Ni plating layer on the surface of the stainless steel plate.

[0100] [Conditions for full-scale Ni plating]

[0101] Ni plating solution (watt bath): nickel sulfate 300g / L, nickel chloride 45g / L, boric acid 35g / L (pH: 3.9)

[0102] ·Plating conditions

[0103] Liquid temperature: 50°C

[0104]Current density: 8A / dm 2

[0105] Next, except adjusting the thickness of the Sn plating layer as shown in Table 2, it carried out similarly to Example 1, and pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com