Perpendicular soilless greening system

A substrate and accommodating cavity technology, applied in the field of greening systems, can solve the problems of long demand, several years of growth, failure to achieve long-term use for many years, secondary pollution of the surrounding environment, etc., to improve the survival rate, save costs, The effect of simple human and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

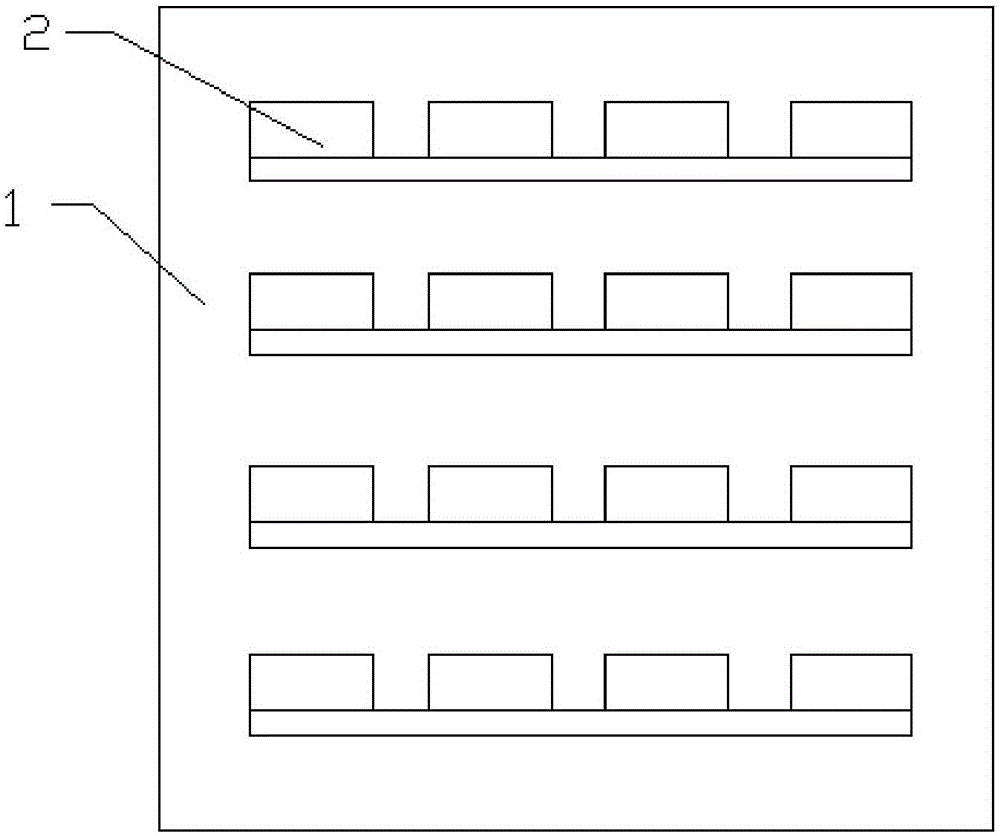

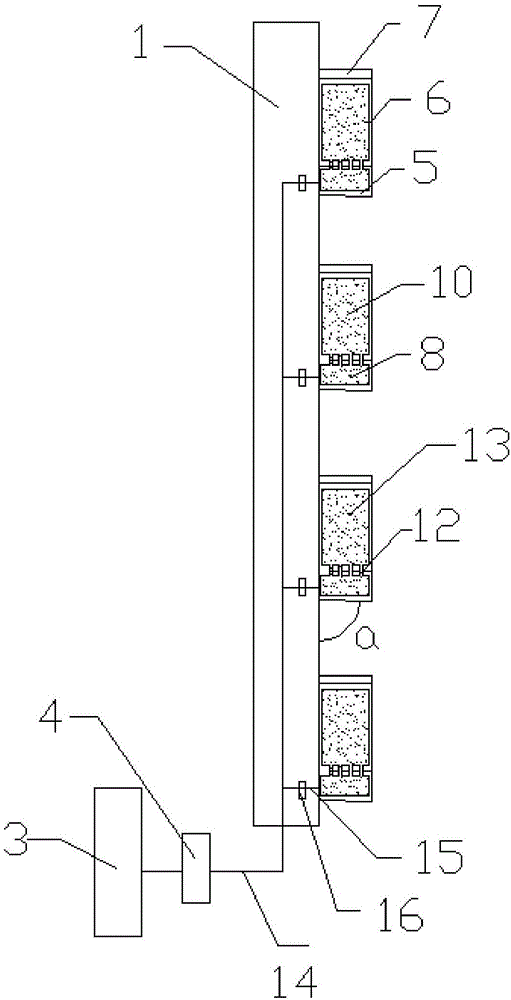

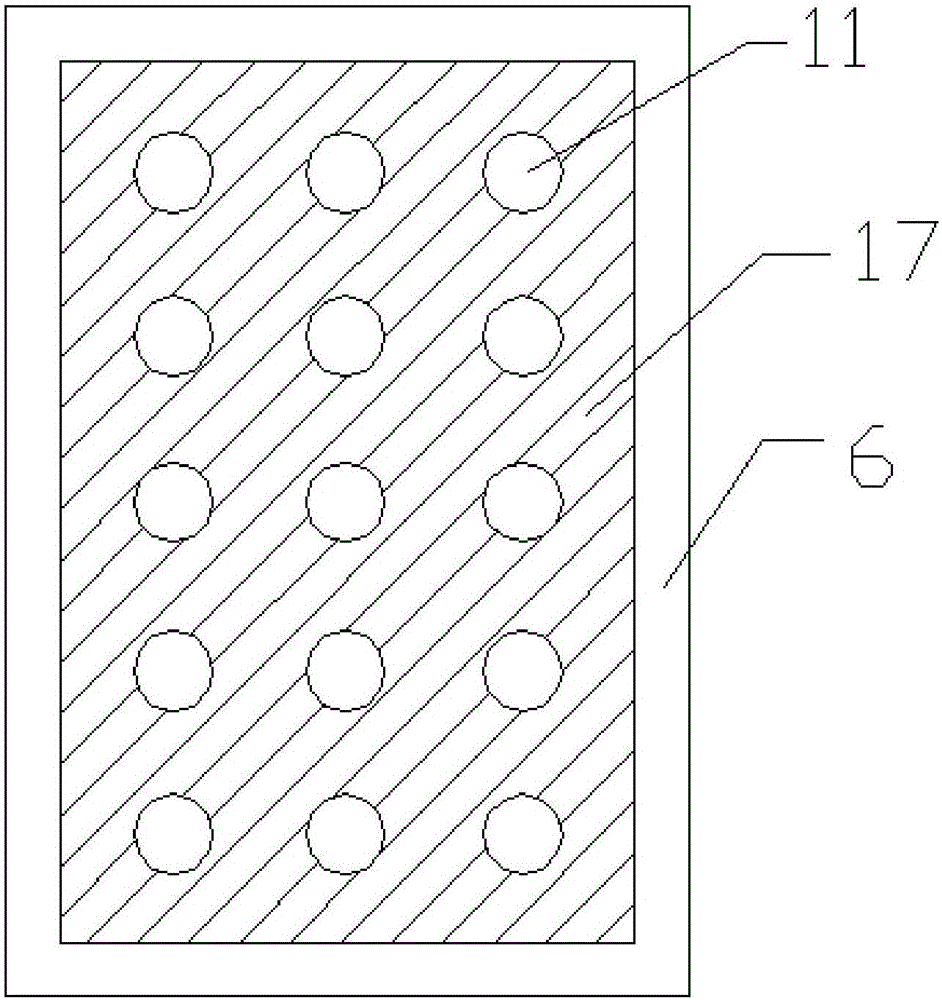

[0033] As shown in the figure, a vertical soilless greening system includes a base plate 1, a cultivation mechanism 2, a liquid storage tank 3 and a booster pump 4. The base plate is arranged vertically, and several groups of cultivation mechanisms are fixed on the base plate parallel to each other. The cultivation mechanism comprises a base 5, a cultivation seat 6 and a cover plate 7, the base is a cuboid structure, and the base is provided with a first accommodating cavity 8, the number of the cultivation seats is at least two, the cultivation seats are fixed on the base, and the cultivation seats are The box structure without a cover, the number of cover plates is the same as that of the cultivation base, the cover plate is fixed on the top of the cultivation base, the cover plate is provided with a number of fixing holes 9, and the cultivation base is provided with a second accommodating cavity 10 The bottom of the cultivation seat is provided with a number of first communi...

Embodiment 2

[0043] A kind of vertical soilless greening system as described in embodiment one, its difference is:

[0044] The preparation method of described nutrient matrix is:

[0045] (1) 5 parts by weight of urea, 1 part of manganese sulfate, 2 parts of potassium chloride, 0.5 part of magnesium nitrate, 3 parts of sodium bicarbonate, 1.2 parts of indole butyric acid, 0.6 part of carbon powder and 50 parts of water Stir at room temperature for 1 h to obtain a mixture A;

[0046] (2) After stirring, heat the mixed solution A, so that the temperature of the mixed solution A is increased at a rate of 2°C / 15min until it rises to 45°C;

[0047] (3) Add 20 parts of humic substances into the mixed solution A in parts by weight, stir at 45° C. for 2 hours to obtain a nutrient matrix, and the stirring speed is 50 r / min.

[0048] The preparation method of described humic substance is:

[0049](1) Add 10 parts of cow dung, 40 parts of mulberry leaves, 15 parts of mulberry, 40 parts of wheat s...

Embodiment 3

[0053] A kind of vertical soilless greening system as described in embodiment one, its difference is:

[0054] The preparation method of described nutrient matrix is:

[0055] (1) 8 parts by weight of urea, 6 parts of manganese sulfate, 9 parts of potassium chloride, 4 parts of magnesium nitrate, 7 parts of sodium bicarbonate, 5.8 parts of indole butyric acid, 3.2 parts of carbon powder and 80 parts of water Stir at room temperature for 3h to obtain a mixture A;

[0056] (2) After stirring, heat the mixed solution A, so that the temperature of the mixed solution A is increased at a rate of 2°C / 15min until it rises to 45°C;

[0057] (3) Add 40 parts of humic substances into the mixed solution A in parts by weight, stir at 45° C. for 4 hours to obtain a nutrient matrix, and the stirring speed is 80 r / min.

[0058] The preparation method of described humic substance is:

[0059] (1) Add 20 parts of cow dung, 60 parts of mulberry leaves, 25 parts of mulberries, 60 parts of whea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com