Milk protein concentrate produced by membrane treatment technology, and preparation method of milk protein concentrate

A milk protein powder and film processing technology, applied in the direction of protein composition, protein food composition, and application of milk, can solve the problems of long supply cycle, unstable supply, large price fluctuation, etc., achieve high added value and increase content , Improve the effect of production structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

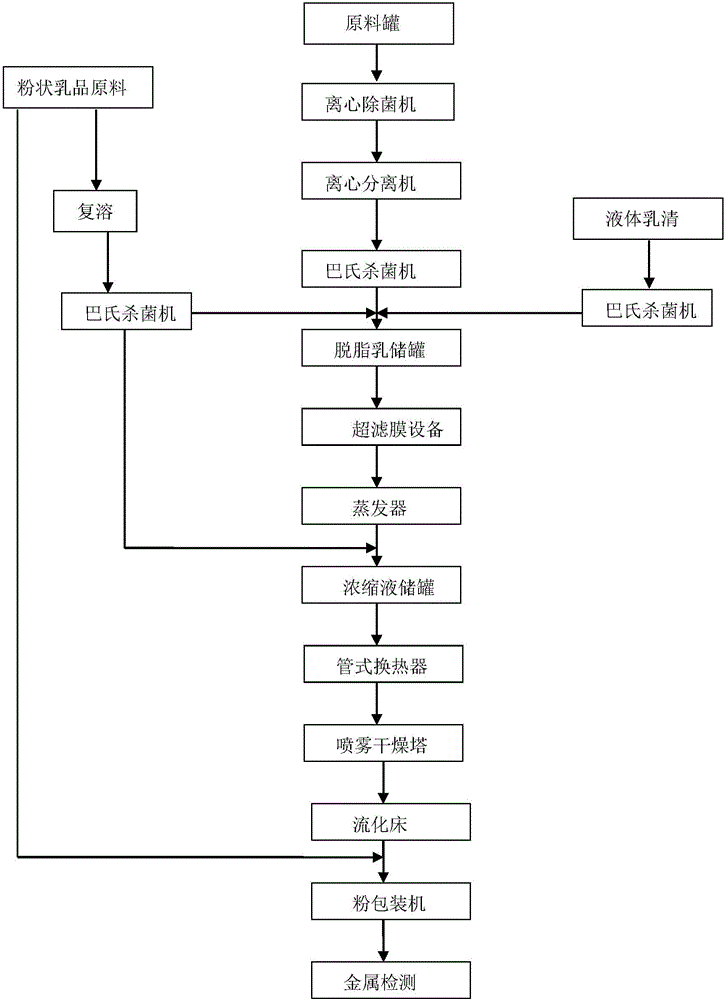

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing concentrated milk protein powder using a membrane treatment process, specifically comprising the following steps:

[0026] (1) Raw milk is temporarily stored in the raw material tank after passing the inspection according to GB 19302. The storage conditions are 2°C for 10 hours;

[0027] (2) After preheating the raw milk to a temperature of 55°C, perform centrifugal sterilization in a centrifugal sterilizer, and then use a centrifugal separator to perform centrifugal separation to obtain skim milk with a fat content of 0.05%;

[0028] (3) Pasteurize the skim milk with a pasteurization machine under the conditions of a temperature of 75° C. for 30 seconds, and then temporarily store it in a skim milk storage tank;

[0029] (4) Transport the skim milk to the ultrafiltration membrane equipment at a flow rate of 9 tons / hour and set the concentration factor to 3.0︰1, control the temperature of the system to ≤50°C, and make the skim milk circulate in th...

Embodiment 2

[0035] A method for preparing concentrated milk protein powder using a membrane treatment process, specifically comprising the following steps:

[0036] (1) Raw milk is temporarily stored in the raw material tank after passing the inspection according to GB 19302. The storage conditions are 4°C for 15 hours;

[0037] (2) After preheating raw milk to a temperature of 63°C, perform centrifugal sterilization in a centrifugal sterilizer, and then use a centrifugal separator to perform centrifugal separation to obtain skim milk with a fat content of 0.06%;

[0038] (3) Utilize the pasteurization machine to carry out pasteurization to the skim milk, the condition is, temperature 80 ℃, time 30 seconds, store temporarily in the skim milk storage tank afterwards; % reconstituted skim milk powder solution, pasteurized, the condition is, temperature 80 ℃, time 30 seconds, then mixed with skim milk and temporarily stored in the skim milk storage tank, wherein, reconstituted skim milk powd...

Embodiment 3

[0045] A method for preparing concentrated milk protein powder using a membrane treatment process, specifically comprising the following steps:

[0046] (1) Raw milk shall be temporarily stored in the raw material tank after passing the inspection according to GB 19302. The storage conditions shall be 5°C for 20 hours;

[0047] (2) After preheating the raw milk to a temperature of 65°C, perform centrifugal sterilization in a centrifugal sterilizer, and then use a centrifugal separator to perform centrifugal separation to obtain skim milk with a fat content of 0.1%;

[0048] (3) Pasteurize the skim milk with a pasteurization machine under the conditions of a temperature of 95° C. for 15 seconds, and then temporarily store it in a skim milk storage tank;

[0049] (4) Transport the skim milk to the ultrafiltration membrane equipment at a flow rate of 15 tons / hour and set the concentration factor to 6.0︰1, control the temperature of the system ≤ 50°C, and make the skim milk circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com