Stable liposoluble nutrient microcapsules as well as preparation method and application thereof

A fat-soluble nutrient and microcapsule technology, applied in the field of medicine and chemical industry, can solve the problems of decline, core material residue, vitamin, carotenoid loss, etc., and achieve the effects of improved pressure resistance, dense protective film, and stable microcapsules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

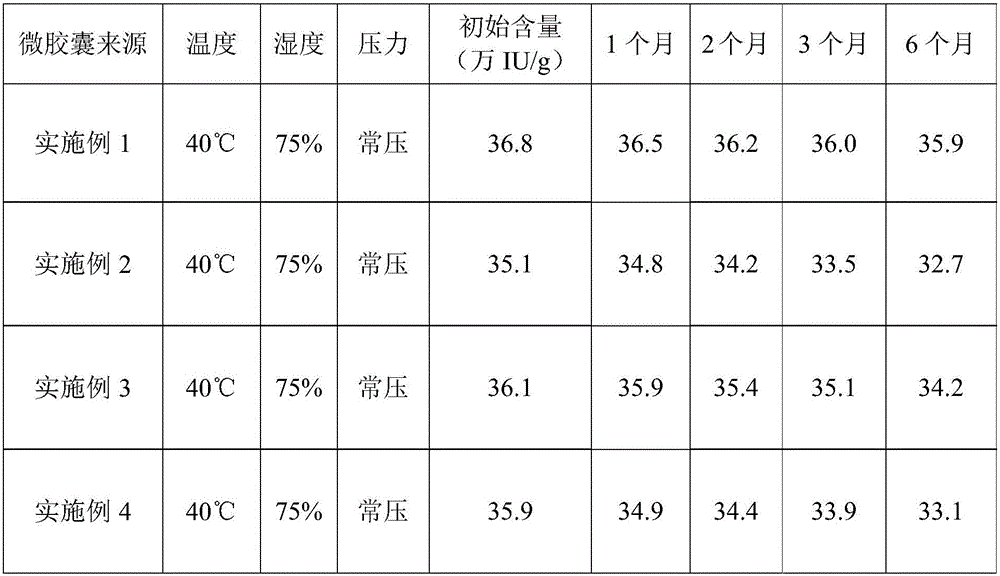

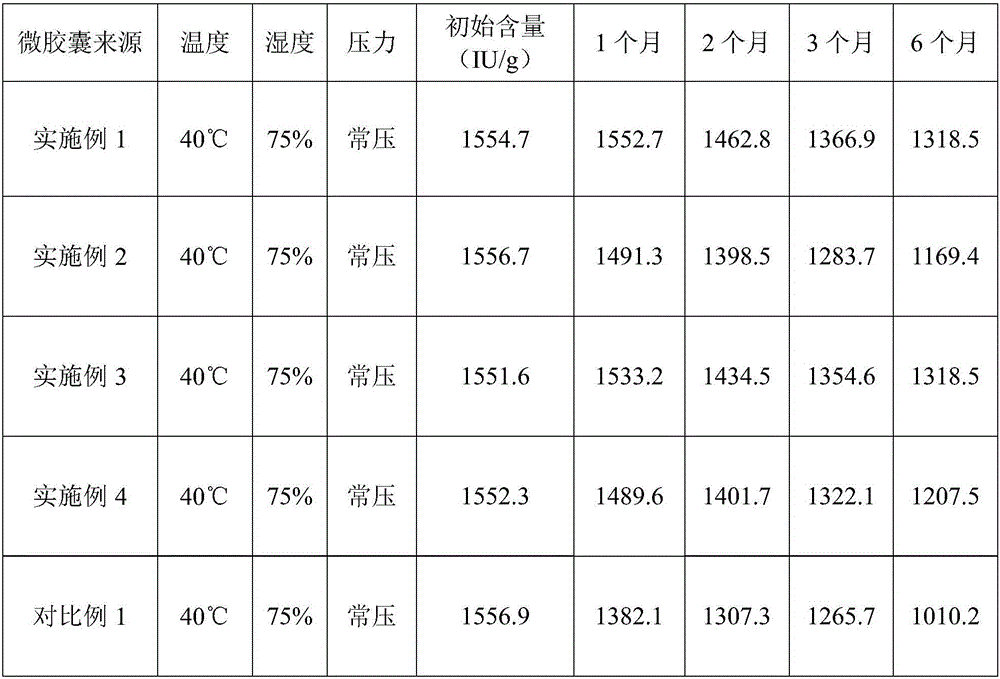

Embodiment 1

[0041] The preparation of embodiment 1 vitamin A acetate microcapsules

[0042] At 60°C, 15 parts by weight of vitamin A acetate, 1 part by weight of ethoxyquin, 4 parts by weight of corn oil, and 70 parts by weight of microcrystalline wax were mixed and dissolved, and then 10 parts by weight of magnesium carbonate was added to disperse them evenly to obtain oily phase. The oil phase is sprayed into a fluidized bed covered with potato starch granules for adsorption and granulation to obtain microcapsules whose surface is coated with starch.

[0043] The temperature in the fluidized bed is set at 50°C, and the sodium hydroxide aqueous solution with a mass concentration of 40% is added by spraying, so that the starch and oil on the surface of the microcapsules are gelatinized and saponified at the same time, and continue to stay in the fluidized bed for 30 minutes after the spraying is completed. , to obtain stable vitamin A acetate microcapsules.

Embodiment 2

[0044] The preparation of embodiment 2 vitamin A acetate microcapsules

[0045] At 60°C, 15 parts by weight of vitamin A acetate, 1 part by weight of ethoxyquin, and 64 parts by weight of corn oil were mixed and dissolved, and then 20 parts by weight of calcium carbonate was added to obtain an oil phase. The oil phase is sprayed into a fluidized bed covered with potato starch granules for adsorption and granulation to obtain microcapsules whose surface is coated with starch.

[0046] The temperature in the fluidized bed is set at 30°C, and a sodium hydroxide solution with a mass concentration of 40% is added to the spray to make the starch and oil on the surface of the microcapsules gelatinize and saponify simultaneously, and stay in the fluidized bed for 40 minutes after the spraying is completed. , to obtain vitamin A acetate microcapsules.

Embodiment 3

[0047] The preparation of embodiment 3 vitamin A acetate microcapsules

[0048] At 60°C, mix and dissolve 15 parts by weight of vitamin A acetate, 1 part by weight of ethoxyquin, 14 parts by weight of corn oil, and 60 parts by weight of microcrystalline wax, and then add 10 parts by weight of calcium carbonate to obtain an oil phase. The oil phase is sprayed into a fluidized bed covered with potato starch granules for adsorption and granulation to obtain microcapsules whose surface is coated with starch.

[0049] The temperature in the fluidized bed is set at 50°C, and a sodium hydroxide solution with a mass concentration of 40% is added to the spray to make the starch and oil on the surface of the microcapsules gelatinize and saponify simultaneously, and continue to stay in the fluidized bed for 40 minutes after the spray is completed. , discharging to obtain vitamin A acetate microcapsules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com