Water cup

A water cup and water quality technology, which is applied to drinking water containers, water pollutants, water/sewage treatment, etc., can solve the problems of serious environmental pollution, can not meet the needs of users for precise and higher levels of use, and achieve the improvement of water quality, Ingenious structural design and enhanced antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

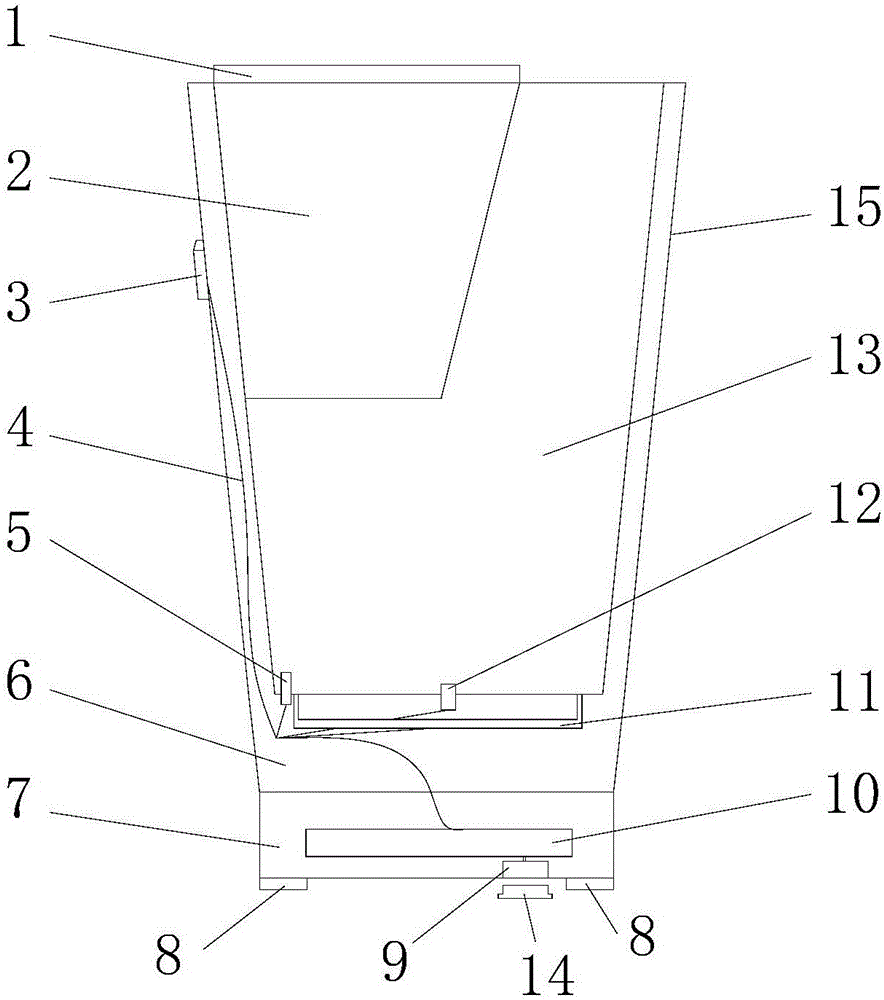

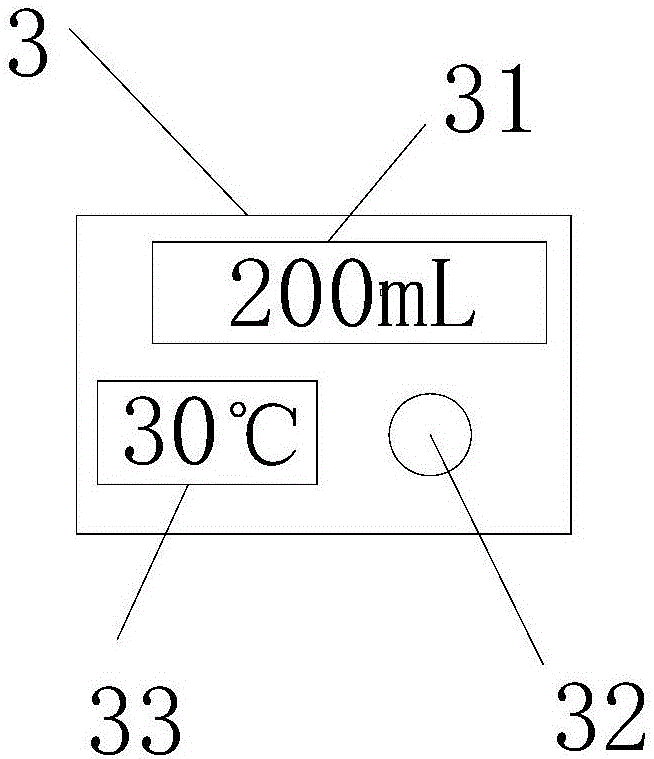

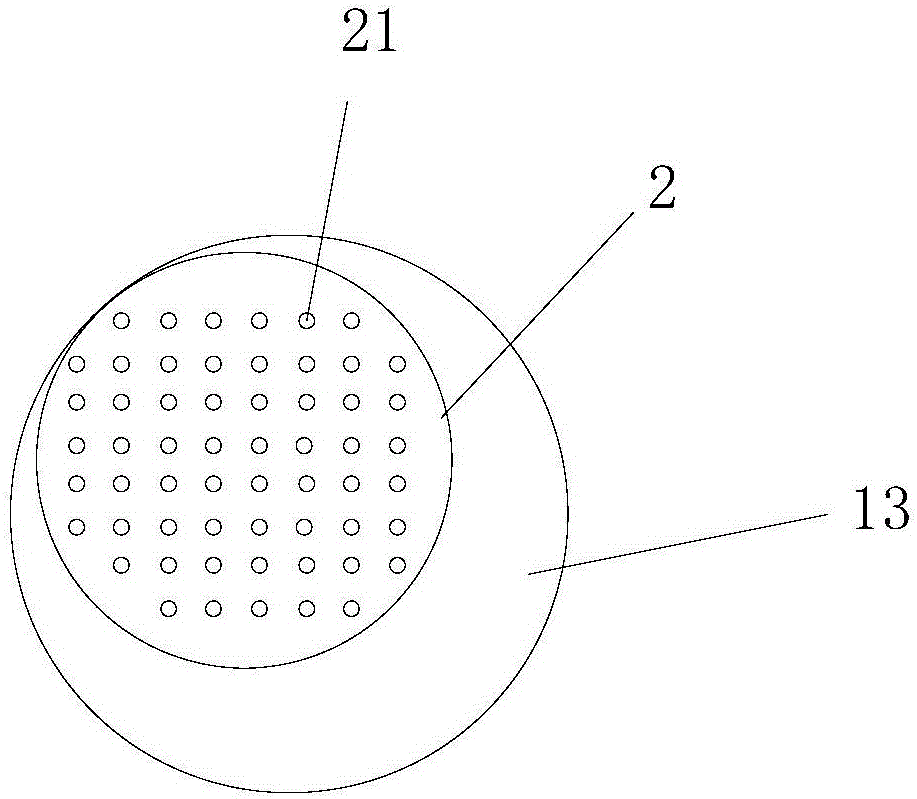

[0043] Such as Figure 1-4 As shown, a water cup includes a cup body with an opening, and the cup body includes a shell 15, an inner container, a base 7, a temperature sensor 5, a water quality detection module, a load cell 11, a display terminal and provides a temperature sensor 5, a water quality The detection module, the load cell 11 and the storage battery 10 that realizes the operation by displaying the electric energy of the terminal; the inner tank includes the inner tank A2 and the inner tank B13, the inner tank A2 is located in the inner tank B13, and the opening of the inner tank A2 is connected to the inner tank B13 The opening of the liner A2 is on the same level, the side wall of the liner A2 is close to the side liner wall of the liner B13, the height ratio of the liner A2 to the liner B13 is 1:2, the opening of the liner A2 and the liner B13 The opening area ratio of the inner container A2 is 2:1, the inner container A2 is provided with a sealing cover 1 matchin...

Embodiment 2

[0057] The working principle is the same as that of Example 1, the difference is:

[0058] 1. The diameter of the small hole 21 is 1mm.

[0059] 2. The bottom of the liner B13 is made of semiconductor refrigeration material; 25 parts of tellurium, 25 parts of bismuth, and 10 parts of antimony are respectively crushed through a 1800-mesh sieve, and then mixed to obtain a mixture, which is then smelted at 635°C for 20 minutes, and then cooled. Semiconductor refrigeration materials are available.

[0060] 3. The liner A is made of filter material, and the filter material is made of the following components by weight: 130 parts of quartz glass carrier, 15 parts of modified polyacrylimide, 3 parts of activated semi-reinforcing carbon black 3 parts of sclareol, 3 parts of specially treated naringin extract powder, 3 parts of magnesium tourmaline powder, 1 part of glyceryl laurate.

[0061] Described liner A2 is made as follows:

[0062] ①: After disinfecting the quartz glass carr...

Embodiment 3

[0068] The working principle is the same as that of Example 1, the difference is:

[0069] 1. The diameter of the small hole 21 is 5mm

[0070] 2. The bottom of the liner B13 is made of semiconductor refrigeration material; 35 parts of tellurium, 25 parts of bismuth, and 15 parts of antimony are respectively crushed through a 1800-mesh sieve, and then mixed to obtain a mixture, which is then smelted at 700°C for 30 minutes, and then cooled. Semiconductor refrigeration materials are available.

[0071] 3. The liner A is made of filter material, and the filter material is made of the following components by weight: 250 parts of quartz glass carrier, 35 parts of modified polyacrylimide, 8 parts of activated semi-reinforcing carbon black 10 parts of sclareol, 8 parts of specially treated naringin extract powder, 10 parts of magnesium tourmaline powder, and 5 parts of glyceryl laurate.

[0072] Described liner A2 is made as follows:

[0073] ①: After disinfecting the quartz glas...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap