A kind of hemostatic material and its preparation method and application

The technology of a hemostatic material and a silo, which is applied to the hemostatic material and its preparation, and the field of a hemostatic kit for preparing the hemostatic material, can solve the problems of slow wound healing, long dialysis purification time, low blood coagulation speed, etc., and achieve the wound healing speed. The effect of fast, short dialysis purification time and high blood coagulation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Example 1: A hemostatic material was prepared by using aldehyde-modified sodium hyaluronate, aldehyde-modified sodium alginate and amine-modified polyaspartic acid hydrazide.

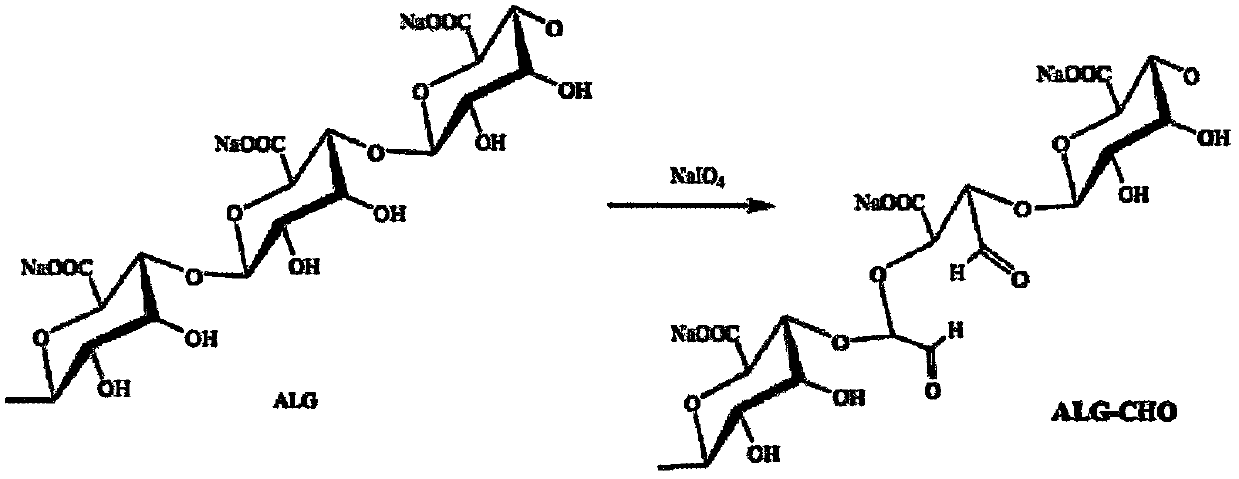

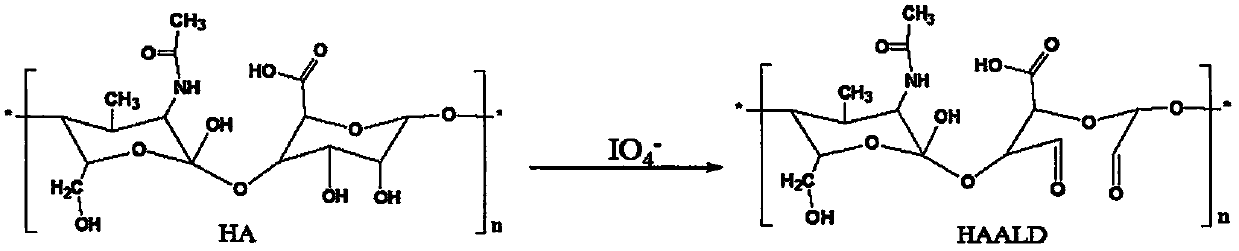

[0081] (1) At 30°C, add 6.5g of sodium periodate to a 5% sodium alginate aqueous solution with a mass concentration of 6.5g, stir and react in the dark for 3 hours, then add ethylene glycol to terminate the reaction, perform ultrafiltration with an ultrafiltration cup, and freeze-dry to obtain Aldehyde-modified sodium alginate with a grafting rate of 30% and a molecular weight of 24700Da;

[0082] (2) At 30°C, add 7.5g of sodium periodate to a 5% hyaluronic acid aqueous solution, and stir the reaction in the dark for 3 hours, then add ethylene glycol to terminate the reaction, perform ultrafiltration with an ultrafiltration cup, and freeze-dry to obtain Aldehyde-modified sodium hyaluronate with a grafting rate of 30% and a molecular weight of 480,000 Da;

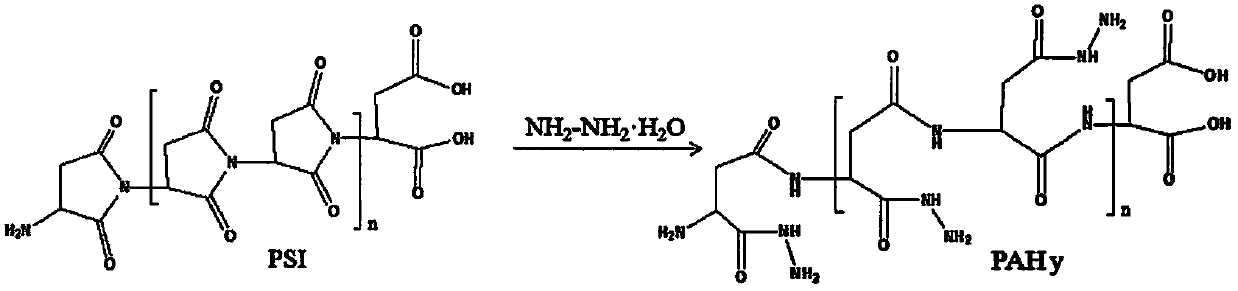

[0083] (3) Dissolve 4g of polysuccinimi...

Embodiment 2

[0085] Example 2: A hemostatic material was prepared by using aldehyde-modified sodium hyaluronate and aldehyde-modified sodium alginate and amine-modified polyaspartic acid hydrazide.

[0086] (1) At 30°C, add 7.5g of sodium periodate to a 5% sodium alginate aqueous solution with a mass concentration of 7.5g, stir and react in the dark for 3 hours, then add ethylene glycol to terminate the reaction, perform ultrafiltration with an ultrafiltration cup, and freeze-dry to obtain Aldehyde-modified sodium alginate with a grafting rate of 36% and a molecular weight of 18200Da;

[0087](2) At 30°C, add 8.5g of sodium periodate to a 5% hyaluronic acid aqueous solution, and stir the reaction in the dark for 3 hours, then add ethylene glycol to terminate the reaction, perform ultrafiltration with an ultrafiltration cup, and freeze-dry to obtain Aldehyde-modified sodium hyaluronate with a grafting rate of 36% and a molecular weight of 320,000 Da;

[0088] (3) Dissolve 4g of polysuccini...

Embodiment 3

[0090] Example 3: A hemostatic material was prepared by using aldehyde-modified sodium hyaluronate, aldehyde-modified sodium alginate and amine-modified polyaspartazide.

[0091] (1) At 30°C, add 8.5g of sodium periodate to a 5% sodium alginate aqueous solution with a mass concentration of 8.5g, stir and react in the dark for 3 hours, then add ethylene glycol to terminate the reaction, perform ultrafiltration with an ultrafiltration cup, and freeze-dry to obtain Aldehyde modified sodium alginate with a molecular weight of 9800Da;

[0092] (2) At 30°C, add 9.5g of sodium periodate to a 5% hyaluronic acid aqueous solution, and stir the reaction in the dark for 3 hours, then add ethylene glycol to terminate the reaction, perform ultrafiltration with an ultrafiltration cup, and freeze-dry to obtain Aldehyde-modified sodium hyaluronate with a grafting rate of 42% and a molecular weight of 230,000 Da;

[0093] (3) Dissolve 4g of polysuccinimide in 20mL of N,N-dimethylformamide, add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com