Aluminum-based metal organic frame-graphene oxide composite material, as well as preparation method and application thereof

An organic framework and composite material technology, applied in the field of materials science and engineering, can solve the problems of composite material preparation failure and other problems, and achieve the effects of easy large-scale production, short time consumption, and excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

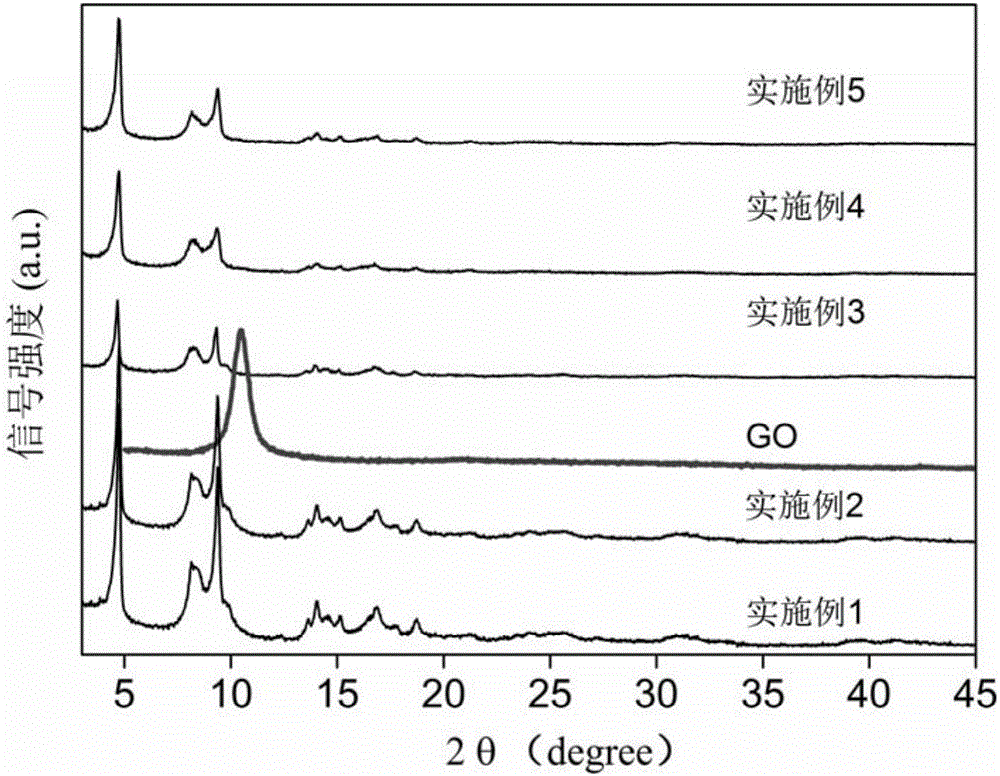

Embodiment 1

[0040] Dissolve 7.60g of aluminum nitrate and 5.0g of terephthalic acid in 300mL of N,N'-dimethylformamide, stir evenly to dissolve completely, stir and react at a constant temperature of 130°C for 12 hours, and cool naturally to room temperature. The filtered product was washed three times with N,N'-dimethylformamide and three times with methanol, and activated under vacuum for 12 hours to obtain a sample and mark it as MIL-68(Al)-1.

Embodiment 2

[0042]Dissolve 5.00g of aluminum chloride and 5.0g of terephthalic acid in 300mL of N,N'-dimethylformamide, stir evenly to dissolve completely, stir and react at a constant temperature of 130°C for 12 hours, and cool naturally to room temperature. The filtered product was washed three times with N,N'-dimethylformamide and three times with methanol, and activated under vacuum for 12 hours to obtain a sample and mark it as MIL-68(Al).

Embodiment 3

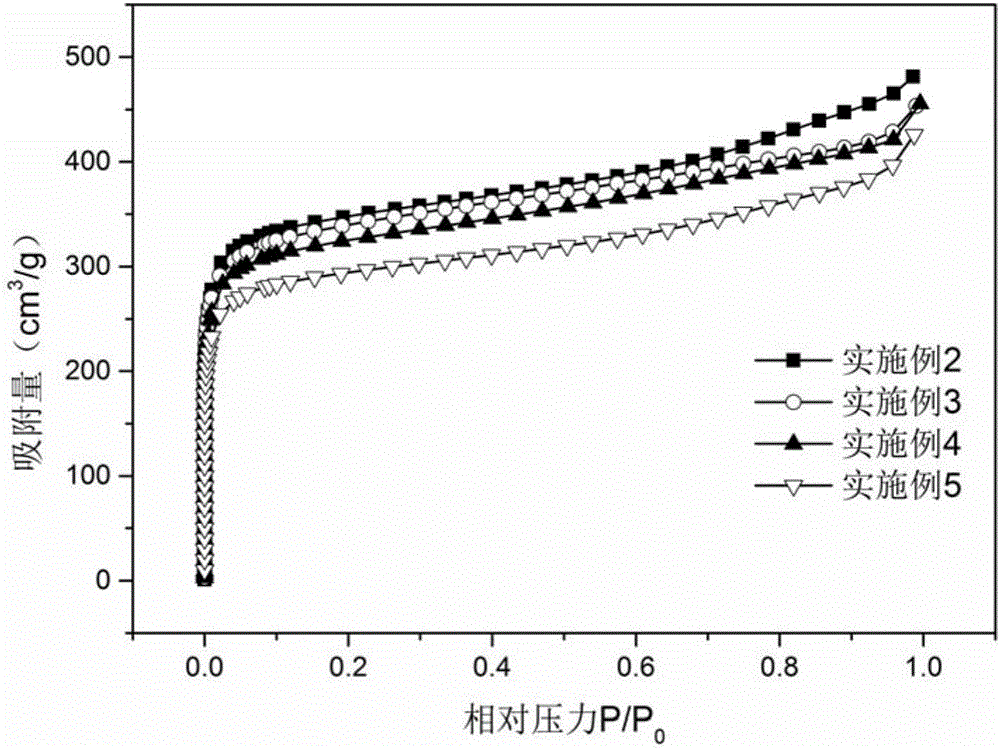

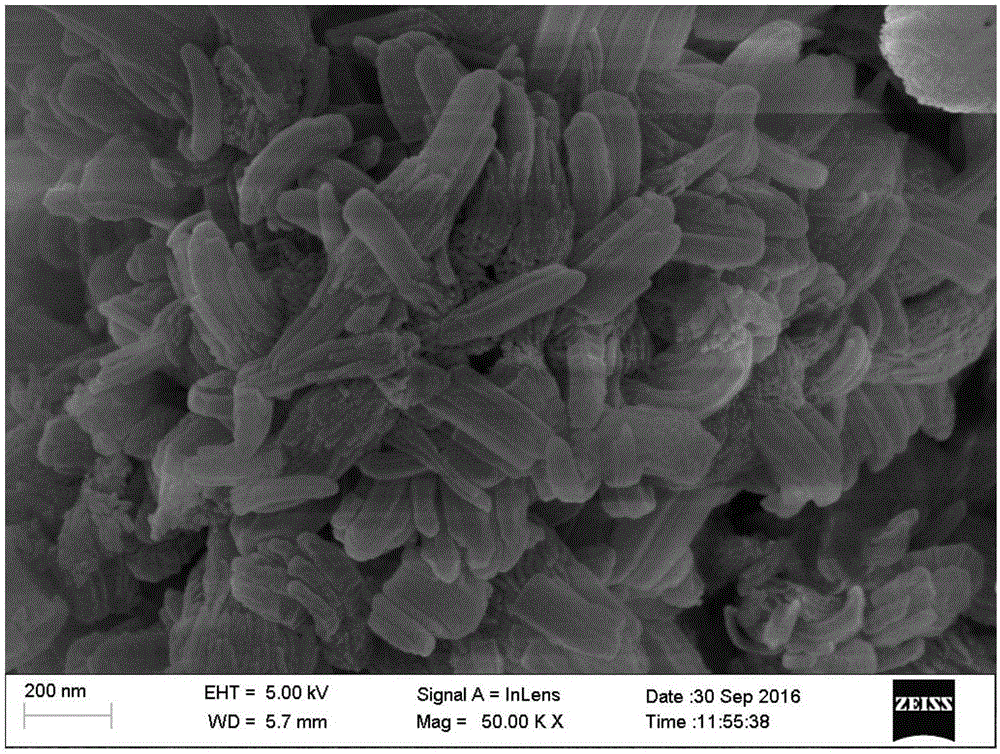

[0043] Example 3: Preparation of Al-based metal-organic framework@graphene oxide composite

[0044] Dissolve 5.00g of aluminum chloride and 5.0g of terephthalic acid in 300mL of N,N'-dimethylformamide, stir evenly to dissolve completely. Then 0.23 g of graphene oxide powder was added and ultrasonically treated to react the mixture; stirred and reacted at a constant temperature of 130° C. for 12 hours, and cooled naturally to room temperature. The filtered product was first washed with N,N'-dimethylformamide for 3 times, deionized water for 3 times, activated at 110°C for 12 hours under vacuum, and labeled as MIL-68(Al)@GO-1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com