Rod-shaped nano nickel-containing metal solid solution catalyst and preparation method thereof

A metal catalyst and solid solution technology, which is applied in the field of rod-shaped nano-nickel-containing metal solid solution catalyst and its preparation, can solve the problems of rare morphology and structure, no reports, etc., and achieve good stability, uniform shape and size, and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

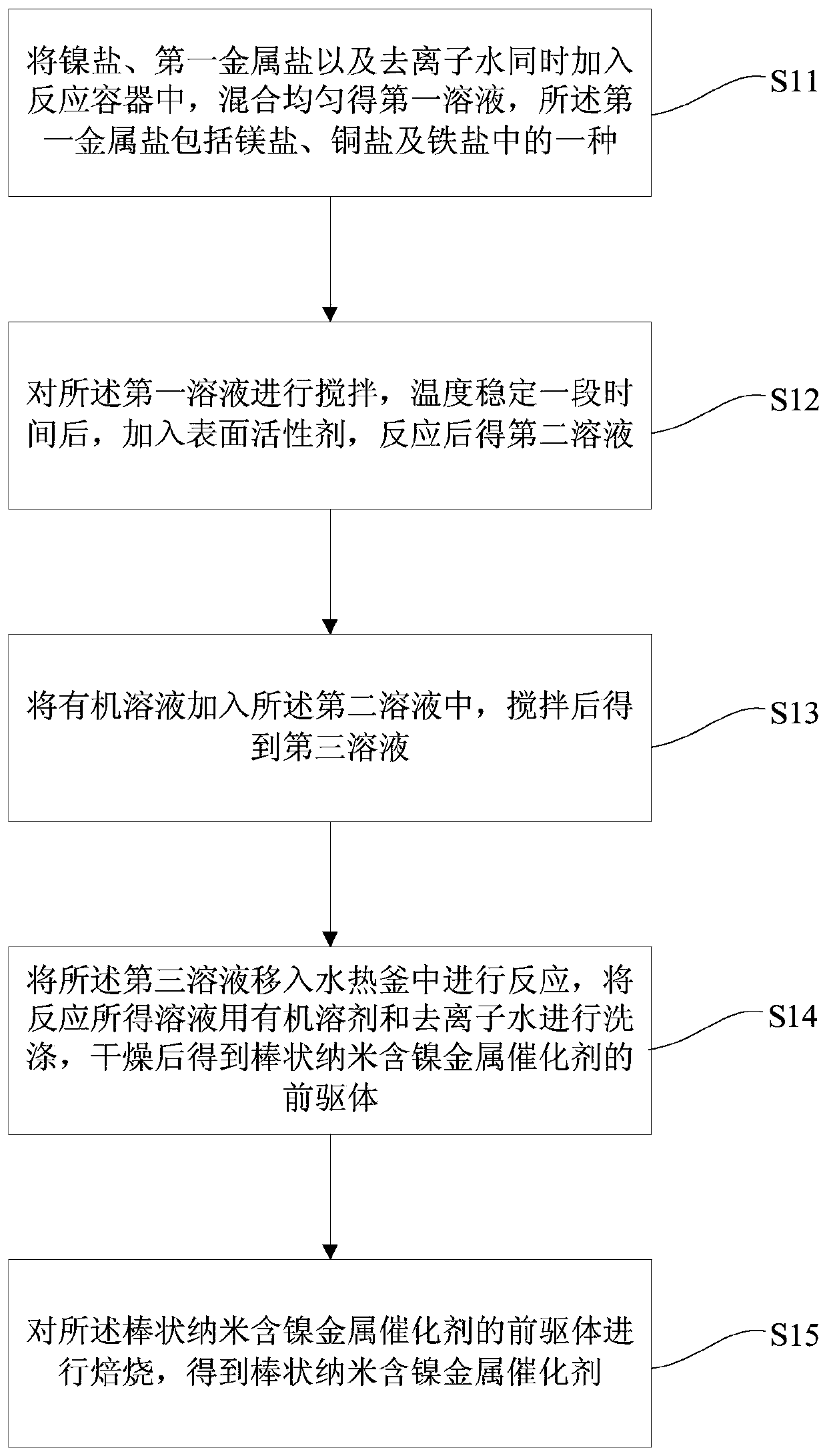

[0030] Such as figure 1 and figure 2 As shown, the present embodiment provides a method for preparing a rod-shaped nano nickel-containing metal solid solution catalyst, comprising the following steps:

[0031] Such as figure 1 As shown, first carry out step 1) S11, add nickel salt, first metal salt and deionized water into the reaction vessel at the same time, mix uniformly to obtain the first solution, and the first metal salt includes magnesium salt, copper salt and iron salt One of.

[0032] As an example, in step 1), the molar ratio of the nickel salt to the first metal salt ranges from 0.2 to 0.6:1, the nickel salt and the first metal salt are nitrate or acetate, and the mixing temperature is Room temperature ~ 70°C, holding time 5 ~ 20min.

[0033] Such as figure 1 As shown, then step 2) S12 is carried out, the first solution is stirred, and after the temperature is stabilized for a period of time, a surfactant is added to obtain the second solution after reaction....

Embodiment 2

[0049] This embodiment provides a method for preparing a rod-shaped nano-nickel-containing metal solid solution catalyst, comprising the following steps:

[0050] Weigh 4mmol of nickel nitrate and 12mmol of magnesium nitrate into a beaker, add 18ml of deionized water, and dissolve at 50°C for 15 minutes to obtain the first solution. The first solution was quickly transferred to a magnetic stirrer, and after the temperature was stabilized for 5 minutes, 1.1 g of polyethylene glycol was added to react for 30 minutes to obtain the second solution. Add 30ml of ethylene glycol to the second solution, and react for 2 hours to obtain the third solution. Move the third solution into a hydrothermal kettle and react at 170°C for 18 hours. After cooling to room temperature, centrifuge the resulting solution and wash it with ethanol and deionized water for 4 times to obtain a light green precursor. Grind the precursor evenly , baked at 650°C for 2h. Finally, the calcined body is ground ...

Embodiment 3

[0052] This embodiment provides a method for preparing a rod-shaped nano-nickel-containing metal solid solution catalyst, comprising the following steps:

[0053] Weigh 4 mmol of nickel acetate and 12 mmol of magnesium acetate into a beaker, add 18 ml of deionized water, and dissolve at a temperature of 50° C. for 15 minutes to obtain the first solution. The first solution was quickly transferred to a magnetic stirrer, and after the temperature was stabilized for 5 minutes, 0.9 g of polyethylene glycol was added to react for 30 minutes to obtain the second solution. Add 30ml of ethylene glycol to the second solution, and react for 2 hours to obtain the third solution. Move the third solution into a hydrothermal kettle and react at 170°C for 18 hours. After cooling to room temperature, centrifuge the resulting solution and wash it with ethanol and deionized water for 4 times to obtain a light green precursor. Grind the precursor evenly , baked at 650°C for 3h. Finally, the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com